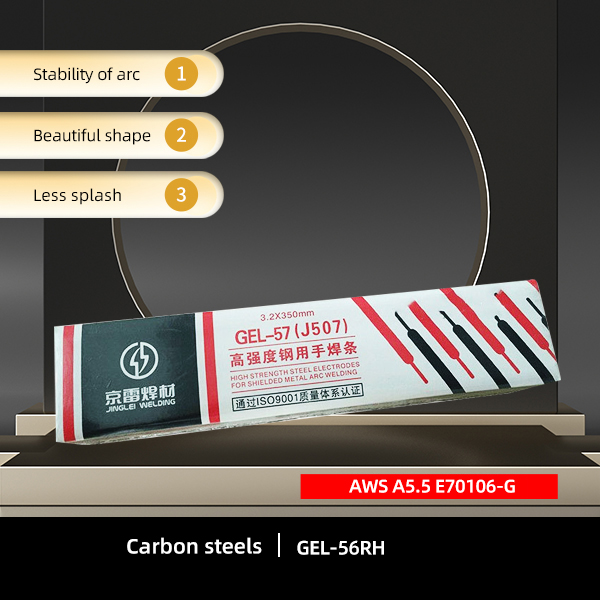

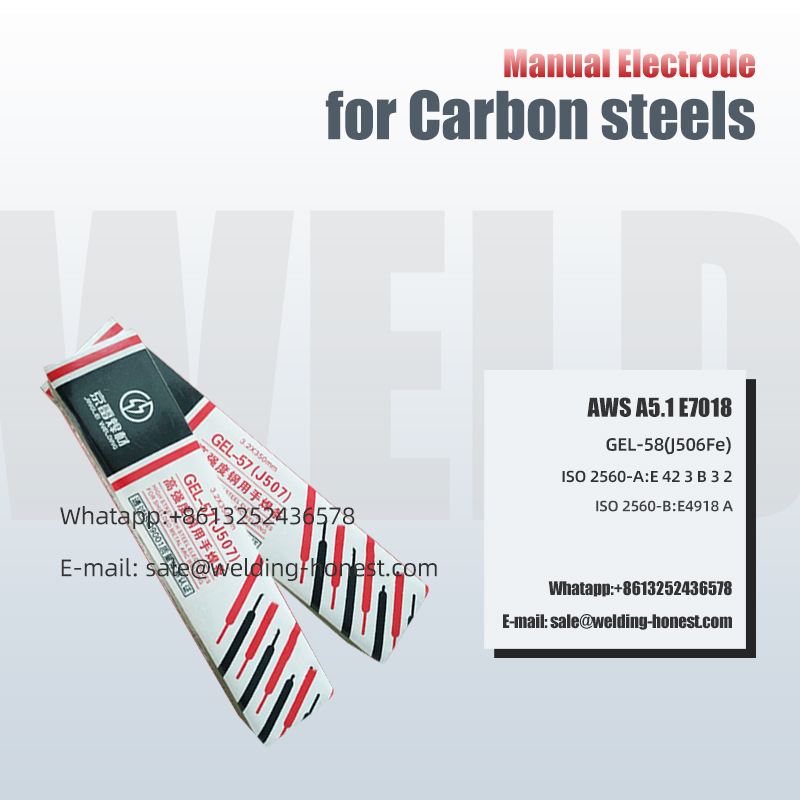

620Mpa Hand Electrode For High Strength Steel

Application&Standard

1. Suitable for low gold alloy steel, medium carbon steel welding, such as construction machinery, port machinery and other occasions.

2. The standard we met: GB/T32533 E5918-G P, AWS A5.5 E9018-G & A5.5M E6218-G, ISO18275-A:E 55 5 1.5NiMo B 3 2, ISO18275-B: E6218-G P

Preheating and inter-channel temperature: 150±15℃, heat treatment according to the welding material standard requirements, 620±15℃*1 hour post-welding heat treatment.

E9016 is a low hydrogen potassium type drug skin of low alloy high strength steel electrode, AC and DC dual use, AC welding, in the performance of stability, slightly inferior to DC welding, used for welding medium carbon steel and the corresponding strength of low alloy high strength steel structure, such as 15MnVN steel. Before welding, the electrode must be baked at 350℃ for 1h, and then used with baking. When the weldment is thick, it should be preheated above 150℃ and cooled slowly after welding.

Features

1. Iron powder low hydrogen hand electrode, high efficiency, stable arc, small splash, good forming, easy desagging, X-ray performance is excellent.

2. It has good crack resistance and stable mechanical properties.

J606 high strength steel electrode model: E9016-G high strength steel electrode characteristics: low hydrogen potassium type low alloy high strength steel electrode, AC and DC dual use, can be welding in full position, AC welding, process performance stability is slightly inferior to DC welding. Purpose: Medium carbon steel and the corresponding strength grade low alloy high strength steel, such as 15MnVN.

Company & Factory

Product composition and mechanical properties introduction

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T RULES | - | ≥1.00 | ≥0.80 | ≥0.30 | ≥0.50 | ≥0.20 | - | - | ≥0.10 |

| AWS RULES | - | ≥1.01 | ≥0.80 | ≥0.30 | ≥0.50 | ≥0.20 | 0.03 | 0.03 | ≥0.11 |

| EXAMPLE VALUE | 0.068 | 1.258 | 0.28 | 0.03 | 1.65 | 0.42 | 0.011 | 0.007 | 0.01 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | ||||||

| GB/T RULES | 490 | 590 | 620*1 | ||||||

| AWS RULES | 530 | 620 | 620*1 | ||||||

| EXAMPLE VALUE | 600 | 685 | 620*1 | ||||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| ELECTRICITY | H/W | 80-110 | 110-130 | 130-180 | 180-230 | ||||

| (Amp) | O/W | 50-80 | 90-120 | 130-160 | - | ||||

NOTE:

H/W: horizontal position welding

O/W: over-head position welding

Typical Cases

Certificate

Product composition and mechanical properties introduction

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T RULES | - | ≥1.00 | ≥0.80 | ≥0.30 | ≥0.50 | ≥0.20 | - | - | ≥0.10 |

| AWS RULES | - | ≥1.01 | ≥0.80 | ≥0.30 | ≥0.50 | ≥0.20 | 0.03 | 0.03 | ≥0.11 |

| EXAMPLE VALUE | 0.068 | 1.258 | 0.28 | 0.03 | 1.65 | 0.42 | 0.011 | 0.007 | 0.01 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | ||||||

| GB/T RULES | 490 | 590 | 620*1 | ||||||

| AWS RULES | 530 | 620 | 620*1 | ||||||

| EXAMPLE VALUE | 600 | 685 | 620*1 | ||||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| ELECTRICITY | H/W | 80-110 | 110-130 | 130-180 | 180-230 | ||||

| (Amp) | O/W | 50-80 | 90-120 | 130-160 | - | ||||

NOTE:

H/W: horizontal position welding

O/W: over-head position welding