China OEM Welding Rod Electrode E7018 E7016

To create much more benefit for shoppers is our enterprise philosophy; client growing is our working chase for China OEM Welding Rod Electrode E7018 E7016, The principle of our organization would be to offer high-quality solutions, professional support, and honest communication. Welcome all good friends to place trial purchase for developing a long-term company relationship.

To create much more benefit for shoppers is our enterprise philosophy; client growing is our working chase for China Welding Rod and Welding Electrode, In order to meet the increasing requirement of customers both home and aboard, we’ll keep carrying forward the enterprise spirit of “Quality, Creativity, Efficiency and Credit” and strive to top the current trend and lead fashion. We warmly welcome you to visit our company and make cooperation.

Application&Standard&Note:

1. Welding ordinary strength of low carbon steel structure and low strength grade of low alloy steel.

2. The standard we met: GB/T5117 E4303, AWS, ISO2560-A:E 35 0 R 1 2, ISO 2560-B: E4303A, JIS Z3211 E4303

1. The insulator must be cooked, and the electrode must be baked at 180°C. When it is being welded in the workshop, it needs to be placed within the insulation cylinder.

2. Pay care when welding: To make sure the welding region is clean, it is vital to remove any oil or other contaminants from a 20mm radius around the weld before welding. The welds must be clean, bright, and free of corrosion. Proper welding form is required (according to the welding manual grinding welding) 3. The welding environment, including the wind and dust. Pay close attention, 4, the rate of welding: a typical welding rod weld length is 40CM.”

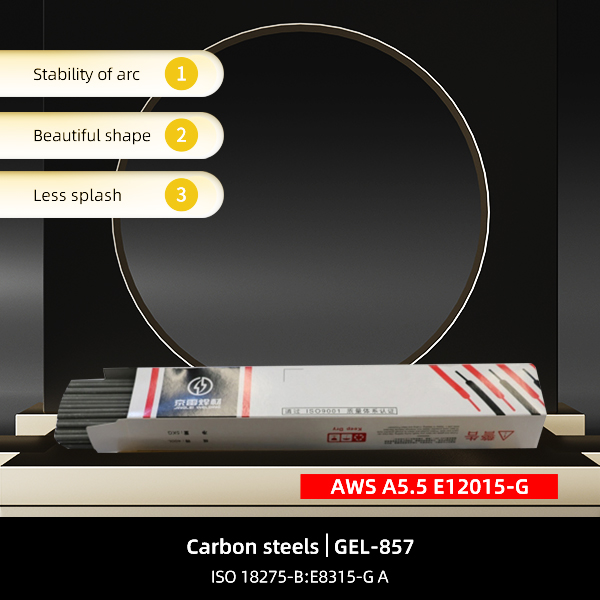

Features

1. Titanium calcium type c hemical skin carbon steel electrode.

2. Stable arc, good slag fluidity, easy slag removal, small splash, beautiful shape.

The Chinese name for the GEM-F03 low carbon hand electrode is J422, while the international label is E4303. J stands for the structural steel electrode, 42 equals 420 kg/mm2, and denotes the tensile strength of the weld metal. It is an acid electrode of the coated titanium calcium type. Used for welding LOW carbon steel structures and low strength grades of low alloy steel, commonly used for welding steel structures and standard carbon steel pipe.”

Company & Factory

Product composition and mechanical properties introduction

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T RULES | 0.2 | 1.2 | 1 | 0.2 | 0.3 | 0.3 | 0.04 | 0.035 | 0.08 |

| AWS RULES | - | - | - | - | - | - | - | - | - |

| EXAMPLE VALUE | 0.076 | 0.5 | 0.38 | 0.025 | 0.01 | 0.028 | 0.016 | 0.01 | 0.008 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | ||||||

| GB/T RULES | 330 | 430 | AW | ||||||

| AWS RULES | - | - | AW | ||||||

| EXAMPLE VALUE | 468 | 538 | AW | ||||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| ELECTRICITY | H/W | 80-120 | 90-140 | 150-190 | 180-240 | ||||

| (Amp) | O/W | 50-80 | 90-120 | 130-160 | - | ||||

NOTE:

H/W: horizontal position welding

O/W: over-head position welding

Typical Cases

Certificate

To create much more benefit for shoppers is our enterprise philosophy; client growing is our working chase for China OEM Welding Rod Electrode E7018 E7016, The principle of our organization would be to offer high-quality solutions, professional support, and honest communication. Welcome all good friends to place trial purchase for developing a long-term company relationship.

China OEM China Welding Rod and Welding Electrode, In order to meet the increasing requirement of customers both home and aboard, we’ll keep carrying forward the enterprise spirit of “Quality, Creativity, Efficiency and Credit” and strive to top the current trend and lead fashion. We warmly welcome you to visit our company and make cooperation.

Product composition and mechanical properties introduction

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T RULES | 0.2 | 1.2 | 1 | 0.2 | 0.3 | 0.3 | 0.04 | 0.035 | 0.08 |

| AWS RULES | - | - | - | - | - | - | - | - | - |

| EXAMPLE VALUE | 0.076 | 0.5 | 0.38 | 0.025 | 0.01 | 0.028 | 0.016 | 0.01 | 0.008 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | ||||||

| GB/T RULES | 330 | 430 | AW | ||||||

| AWS RULES | - | - | AW | ||||||

| EXAMPLE VALUE | 468 | 538 | AW | ||||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| ELECTRICITY | H/W | 80-120 | 90-140 | 150-190 | 180-240 | ||||

| (Amp) | O/W | 50-80 | 90-120 | 130-160 | - | ||||

NOTE:

H/W: horizontal position welding

O/W: over-head position welding