China wholesale Hard-Facing Metal Jointing Stuff Supplier - Hard-facing SAW welding wire and welding flux weld fabrication stuff – Honest Metal

China wholesale Hard-Facing Metal Jointing Stuff Supplier - Hard-facing SAW welding wire and welding flux weld fabrication stuff – Honest Metal Detail:

Application & Standard

This hard surface WEAR-resistant hand electrode is mainly suitable for low impact, intense wear parts, such as civil construction machinery surfacing regeneration, especially dredging machinery, bucket, sand suction pump. Surfacing is a welding method in which the surface or edge of steel parts is fused with a layer of wear resistance, corrosion resistance, high temperature resistance and other characteristics of metal materials. To repair and improve the service life of parts, effective use of raw materials, improve product performance, cost control has obvious economic benefits. The standard of surfacing is very complex. It is necessary to adopt suitable welding wire according to different rules. Different surfacing processes should be used for different steel parts and surfacing electrodes to obtain satisfactory actual surfacing results.

Features

This is a low sodium hydrogen coating type surfacing electrode, high hardness, no need of heat treatment, can not continue cutting, good wear resistance. Wear – resistant correct operation process can ensure that all the skin can be melted into the molten pool through the arc during fusion welding. And weld core, substrate surface metal rapidly melting to produce a new wear-resistant alloy. At the same time, efforts should be made to improve the carbon content of the electrode on the premise of ensuring that the welding layer has excellent crack resistance. Promote the formation of various carbides, increase its wear resistance. For the parts that bear impact and abrasive wear at the same time in the work, such as the hammer head of the crusher, lining plate, cage rod, etc. The above welding layer is far from meeting the requirements of its working conditions, and a completely different operation process must be adopted.

Company & Factory

Product composition and mechanical properties introduction

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | P | S |

| GB/T RULES | 0.50-0.80 | 0.50-1.50 | 1.00 | 4.00-8.00 | 0.035 | 0.035 |

| AWS RULES | - | - | - | - | - | - |

| EXAMPLE VALUE | 0.64 | 1.35 | 0.94 | 7 | 0.027 | 0.007 |

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| ELECTRICITY (Amp) |

80-120 | 120-160 | 160-210 | |||||

TYPICAL CASES

Certificates

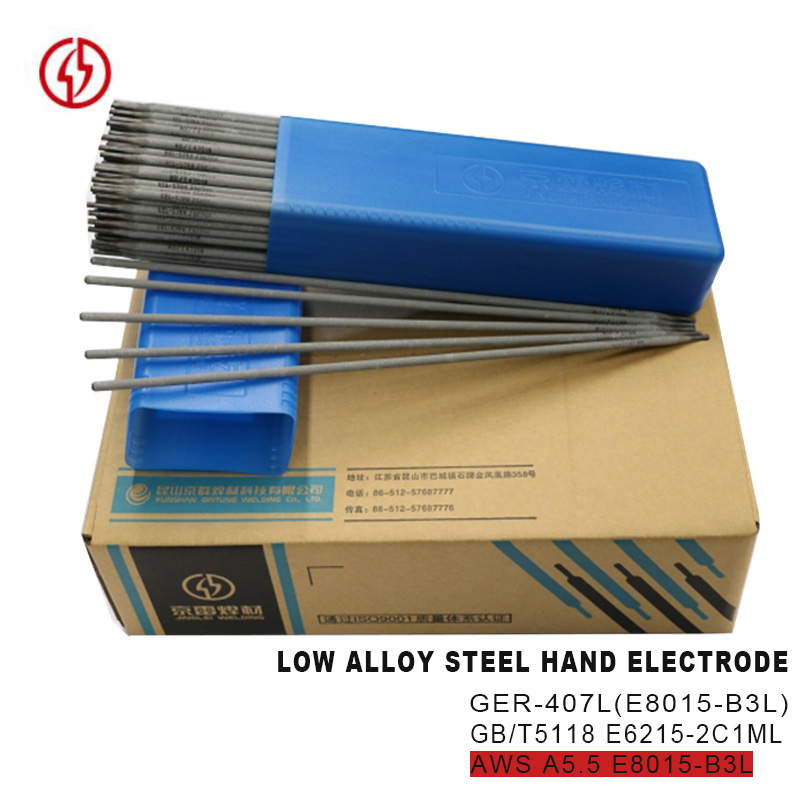

Product detail pictures:

Related Product Guide:

We've one of the most innovative manufacturing devices, experienced and qualified engineers and workers, recognized good quality handle systems and also a friendly experienced income team pre/after-sales support for China wholesale Hard-Facing Metal Jointing Stuff Supplier - Hard-facing SAW welding wire and welding flux weld fabrication stuff – Honest Metal , The product will supply to all over the world, such as: Salt Lake City, Suriname, Latvia, To meet the requirements of individual customers for each bit more perfect service and stable quality products. We warmly welcome customers around the world to visit us, with our multi-faceted cooperation, and jointly develop new markets, create a brilliant future!

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!