China wholesale Hard-Facing Weld Fabrication Materials Manufacturers - Hard-facing Flux cored wire weld fabrication stuff – Honest Metal

China wholesale Hard-Facing Weld Fabrication Materials Manufacturers - Hard-facing Flux cored wire weld fabrication stuff – Honest Metal Detail:

Application & Standard

GEH-80 hardface wear-resistant hand welding electrode is mainly used for surfacing or repairing parts working under impact load conditions with abrasive wear, such as bulldozer blade plate, dredging bucket teeth, concrete mixer blades, hydraulic machinery and mining machinery parts. Safety precautions in the process of wear-resistant electrode welding:

When the welding site is wet, the welder should stand on the dry insulation board or rubber pad, and the cooperating personnel should wear insulation shoes or stand on the insulation board or rubber pad.

When wear-resistant electrode welding preheating workpiece, there should be insulation measures such as asbestos cloth or baffle.

When removing welding slag, protective glasses or face mask should be worn, and the head should avoid the direction of knocking welding slag splashing to prevent iron slag splashing wounding people.

Features

GEH-80 is a low sodium hydrogen communication medium and low alloy steel surfacing electrode, excellent technology; It is generally used for surfacing of spare parts under normal temperature and non-corrosive conditions. Due to the high carbon content and poor toughness, it is best to use alkaline structural steel electrode (such as J507) as the base for welding.

When using arc air gouging root, protective glasses or face mask should be worn to prevent injury caused by iron slag splashing.

When multiple welders are welding together at the same time, the welding platform or weldment must be grounded, and a light-proof shed must be set up.

When TURNING MACHINERY and equipment for welding, power must be cut off and safety signs of “repair and construction, no operation” must be set up or special personnel should be responsible for guarding.

Company & Factory

Product composition and mechanical properties introduction

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | P | S |

| GB/T RULES | - | - | - | - | - | - |

| AWS RULES | - | - | - | - | - | - |

| EXAMPLE VALUE | 0.45 | 0.72 | 1.93 | 8.3 | 0.027 | 0.006 |

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| ELECTRICITY (Amp) |

80-120 | 120-160 | 160-210 | |||||

TYPICAL CASES

Certificates

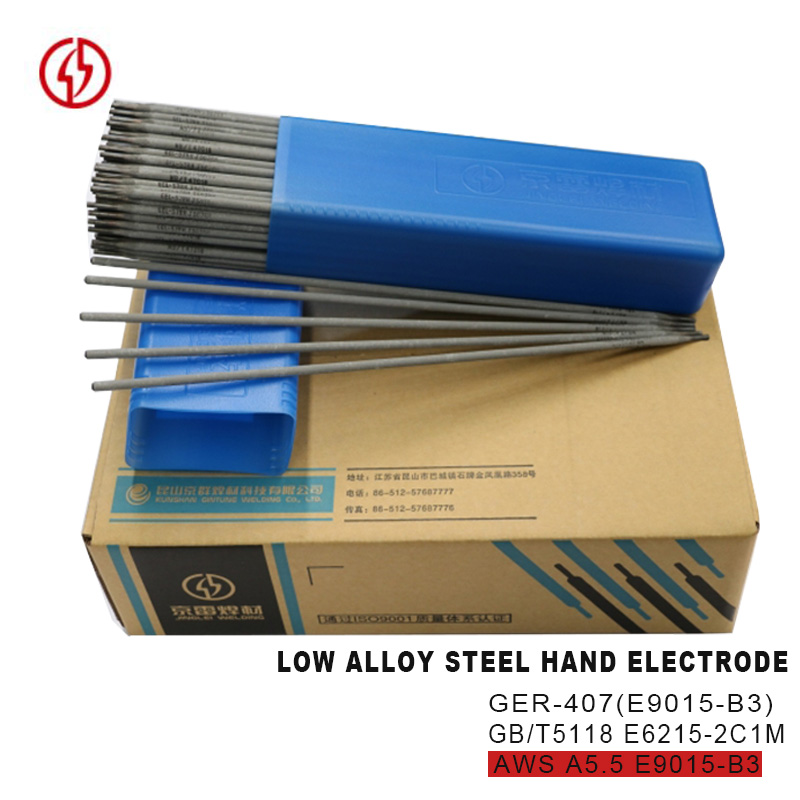

Product detail pictures:

Related Product Guide:

We continue to keep increasing and perfecting our solutions and service. At the same time, we operate actively to do research and enhancement for China wholesale Hard-Facing Weld Fabrication Materials Manufacturers - Hard-facing Flux cored wire weld fabrication stuff – Honest Metal , The product will supply to all over the world, such as: Myanmar, Canada, United Arab Emirates, Aiming to grow to be by far the most experienced supplier within this sector in Uganda, we keep researching on the creating procedure and raising the high quality of our principal merchandise. Till now, the merchandise list has been updated on a regular basis and attracted customers from around the globe. In depth data can be obtained in our web page and you'll be served with good quality consultant service by our after-sale team. They're about to make it possible for you to get complete acknowledge about our things and make a satisfied negotiation. Small business check out to our factory in Uganda can also be welcome at any time. Hope to obtain your inquiries to get a happy co-operation.

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.