China wholesale Hard-Facing Welding Materials Suppliers - Hard-facing SAW welding wire and welding flux weld fabrication accessories – Honest Metal

China wholesale Hard-Facing Welding Materials Suppliers - Hard-facing SAW welding wire and welding flux weld fabrication accessories – Honest Metal Detail:

Application & Standard

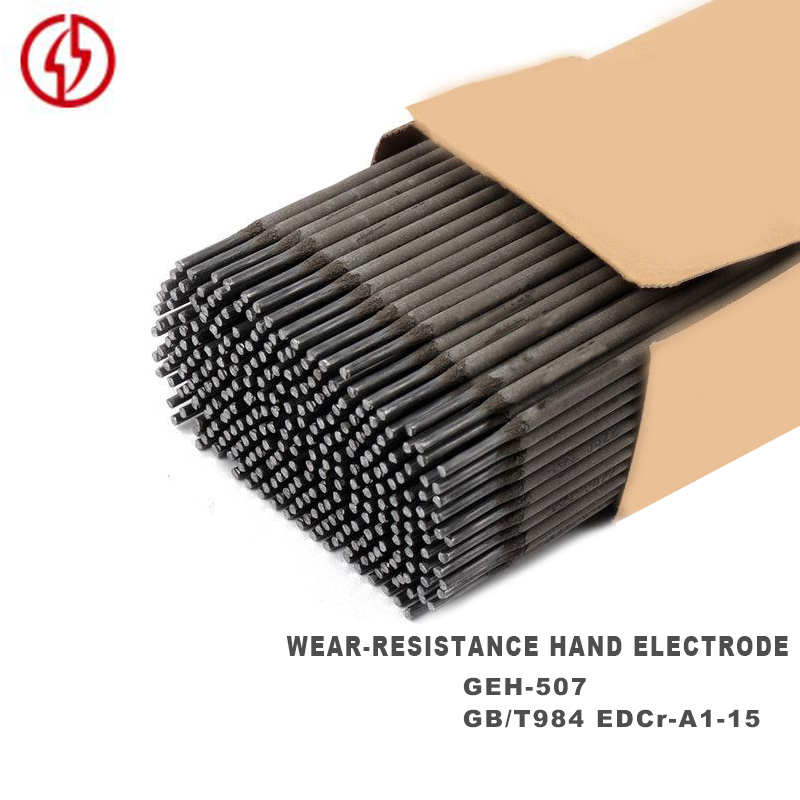

This product is mainly used for surfacing the valves and other sealing parts of high-rise boiler units in power stations working at 570℃ or below. Adopt DC reverse connection. The surfacing metal is 1Cr13 semi-ferritic high chromium steel. Generally no heat treatment is required during welding, and the hardness is uniform. It can be annealed and softened at 750-800℃. When heated to 900-1000℃, it can be re-hardened by air cooling or oil quenching. This hand electrode is also used for surfacing of shaft and valve of carbon steel or alloy steel at working temperature below 450℃. The hardness of the surfacing layer should be controlled at about 40.

Features

GEH-507 is China GB/T984EDCr-A1-15 under a low sodium hydrogen type high chromium steel for valve surfacing welding electrode, good operation, less splash, easy slag removal, beautiful shape, can be easily mechanical processing. And the surfacing layer has the characteristics of air quenching, high medium-temperature hardness and good corrosion resistance. This TYPE OF ELECTRODE IS often USED FOR metal wear and moisture, weak acid and other action of parts, such as valve sealing surface, mixer slurry, etc. Before welding, it must be dried at 300-350℃ for 1 hour. To remove the base material surface moisture, rust stains, oil. And we should pay attention to the way of arc and arc. After the arc will arc back burning, remelting arc point, when the arc to fill the arc pit.

Company & Factory

Product composition and mechanical properties introduction

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | P | S |

| GB/T RULES | 0.15 | - | - | 10.00-16.00 | 0.04 | 0.03 |

| AWS RULES | - | - | - | - | - | - |

| EXAMPLE VALUE | 0.12 | 0.60 | 1.00 | 12.8 | 0.025 | 0.008 |

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| ELECTRICITY (Amp) |

80-120 | 120-160 | 160-210 | |||||

TYPICAL CASES

Certificates

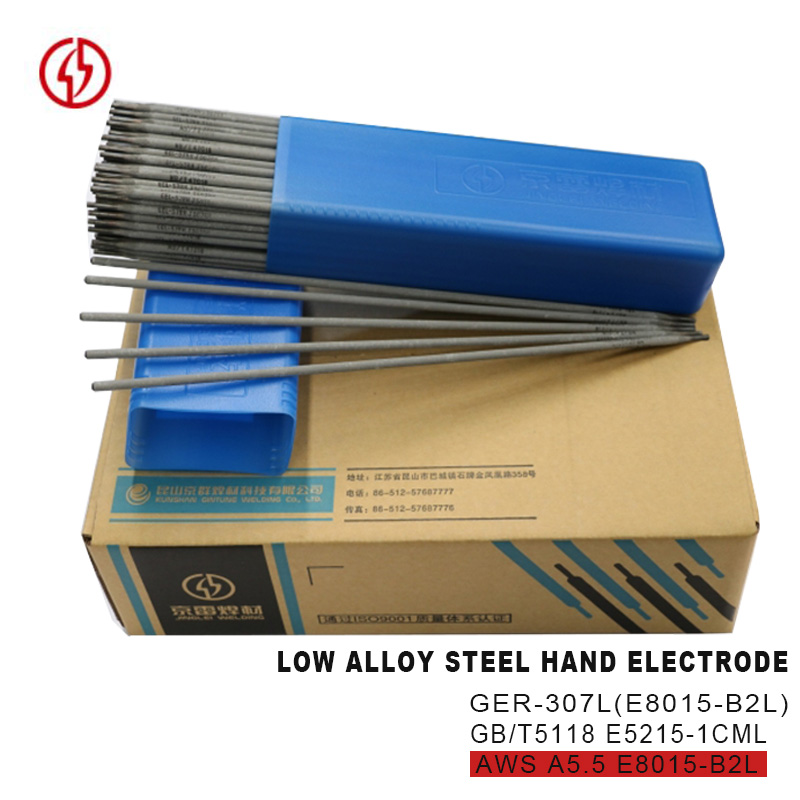

Product detail pictures:

Related Product Guide:

Our development depends on the advanced equipment ,excellent talents and continuously strengthened technology forces for China wholesale Hard-Facing Welding Materials Suppliers - Hard-facing SAW welding wire and welding flux weld fabrication accessories – Honest Metal , The product will supply to all over the world, such as: Belgium, Guinea, Swedish, We are fully aware of our customer's needs. We provide high quality products, competitive prices and the first class service. We would like to establish good business relationships as well as friendship with you in the near future.

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,