China wholesale Low-Alloy Steels E8015-B8 Welding Makings Manufacturers - AWS 8015-B6 Low-alloy steels Manual electrode Welding makings – Honest Metal

China wholesale Low-Alloy Steels E8015-B8 Welding Makings Manufacturers - AWS 8015-B6 Low-alloy steels Manual electrode Welding makings – Honest Metal Detail:

Application&Standard&Note:

AWS E8015-B6 heat-resistant steel electrodes are mainly used for high temperature hydrogen corrosion resistant pipelines with operating temperature below 400℃, such as Cr5Mo, A213-T5,A335-P5, etc. In addition, DC reverse welding operation and short arc welding operation can be adopted, and full-position welding can also be carried out. The weldment needs to be properly preheated and post-welding heat treatment according to the structural characteristics. Construction organization is also an important link affecting the quality of welding, the cooperation of each type of work is particularly important, to avoid the quality of the whole weld due to the next process is not connected, should also pay attention to the influence of weather environment. When the ambient temperature is low, increase the preheating temperature appropriately to prevent the temperature from falling too fast. At the same time, take emergency measures such as wind and rain prevention.

Features

AWS E8015-B6 hand electrode for heat resistant steel perlite heat resistant steel electrode with low sodium hydrogen coating containing Cr5%-Mo-V has high temperature resistance to hydrogen corrosion and stable mechanical properties. It has the characteristics of stable arc, less splashing, good forming, easy desagging and excellent X-Ray performance. Before welding, it shall be preheated to 175~230℃(this temperature must be maintained during the whole welding process), and after welding, it shall be heat treated at 740±15℃*1h according to the standard requirements of welding materials.

Company & Factory

Product composition and mechanical properties introduction

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Mo | P | S | Ni |

| GB/T RULES | 0.12 | 0.5-0.9 | 0.50 | 4.5-6.0 | 0.40-0.70 | 0.03 | 0.030 | 0.40 |

| AWS RULES | 0.05-0.10 | 1.00 | 0.90 | 4.5-6.0 | 0.45-0.65 | 0.03 | 0.030 | 0.40 |

| EXAMPLE VALUE | 0.077 | 0.75 | 0.35 | 5.2 | 0.52 | 0.016 | 0.012 | 0.007 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | |||||||||

| GB/T RULES | 460 | 550 | 740*1 | - | 14 | |||||||||

| AWS RULES | 460 | 550 | 740*1 | - | 19 | |||||||||

| EXAMPLE VALUE | 530 | 630 | 740*1 | 160/Nature temperature | 23 | |||||||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | ||||||

| ELECTRICITY (Amp) |

H/W | 80-110 | 100-130 | 130-180 | 170-210 | |||||

| O/W | 60-100 | 80-120 | 120-160 | - | ||||||

PACKING DETAILES:

| SEPCIFICATION | LENGTH | PCS/1KG | WEIGHT/1KG | |||

| 2.6mm | 300mm | 48PCS | 2KG | |||

| 3.2mm | 350mm | 27PCS | 5KG | |||

| 4.0mm | 350mm | 16PCS | 5KG | |||

| 5.0mm | 350mm | 12PCS | 5KG | |||

NOTE:

H/W: horizontal position welding

O/W: over-head position welding

Typical Cases

Certificate

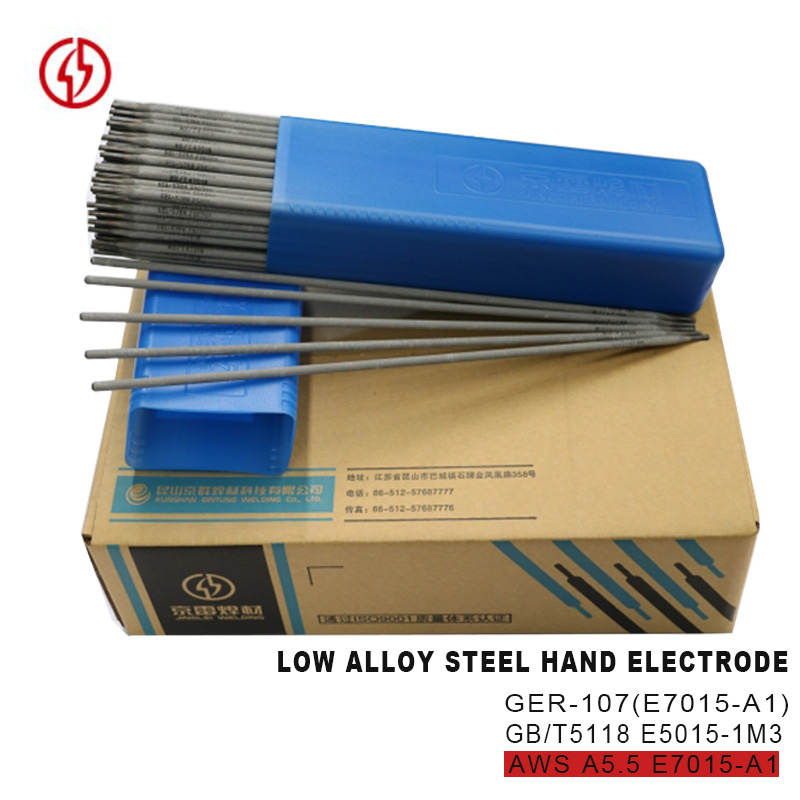

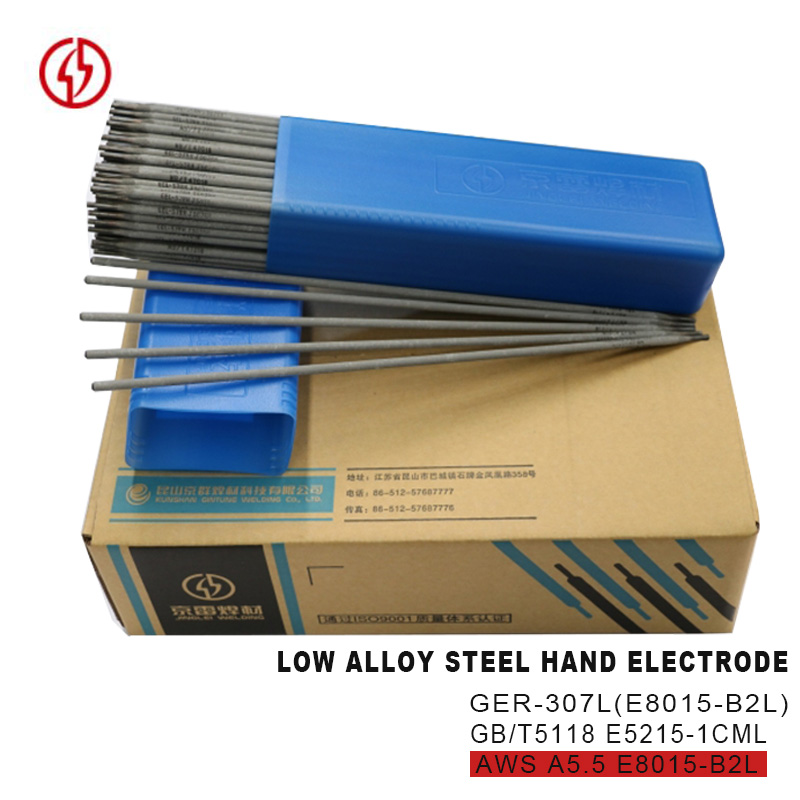

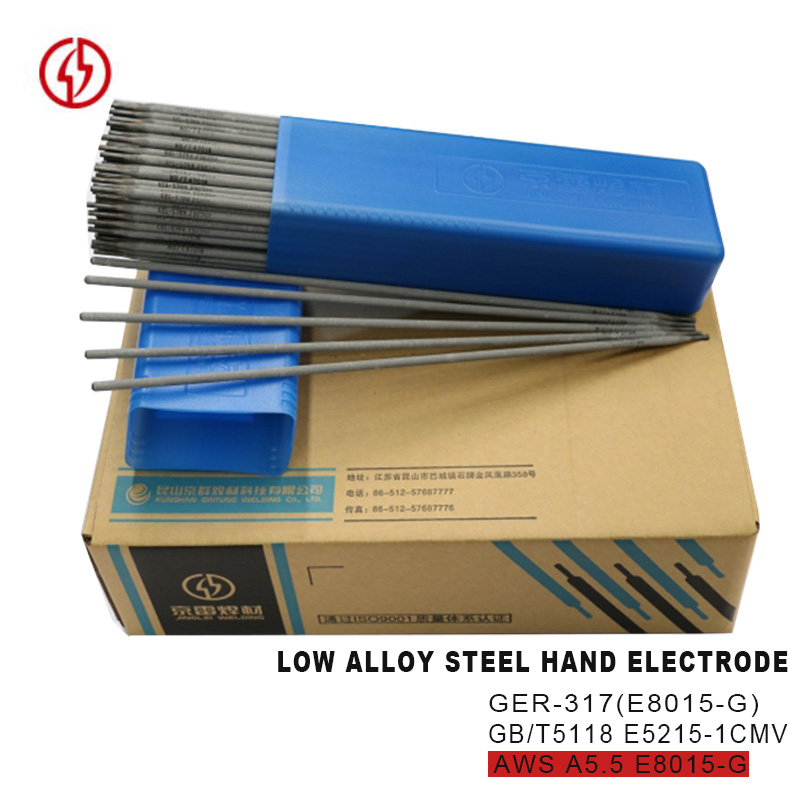

Product detail pictures:

Related Product Guide:

Persisting in High quality, Prompt Delivery, Aggressive Price, now we have established long-term cooperation with consumers from equally overseas and domestically and get new and old clients' large comments for China wholesale Low-Alloy Steels E8015-B8 Welding Makings Manufacturers - AWS 8015-B6 Low-alloy steels Manual electrode Welding makings – Honest Metal , The product will supply to all over the world, such as: Mexico, Uganda, Chicago, With strong technical strength and advanced production equipment, and SMS people purposefully , qualified, dedicated spirit of enterprise. Enterprises took the lead through the ISO 9001:2008 international quality management system certification, CE certification EU ; CCC.SGS.CQC other related product certification. We look forward to reactivating our company connection.

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!