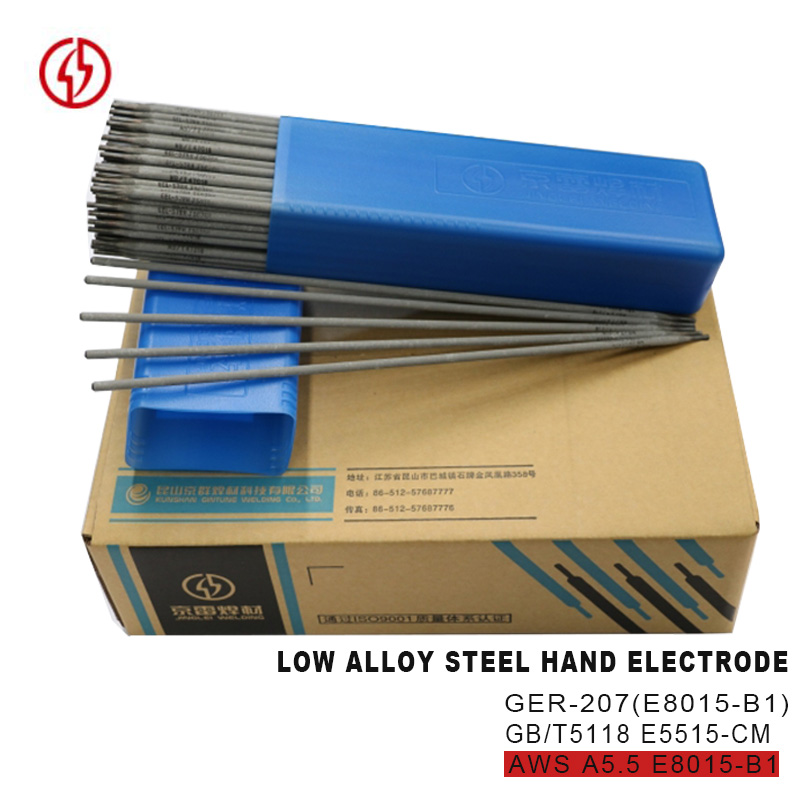

China wholesale Welding Connection Supplier - AWS E8015-B1 Low-alloy steels Manual electrode Welding stuff – Honest Metal

China wholesale Welding Connection Supplier - AWS E8015-B1 Low-alloy steels Manual electrode Welding stuff – Honest Metal Detail:

Application&Standard&Note:

GER-207 heat resistant steel hand welding rod (R207)0.5%Cr-0.5%Mo steel hand welding rod is suitable for welding CrMo pearlite heat resistant steel and high temperature, high pressure pipeline, chemical containers and other corresponding steel, such as 12CrMo tube plate, A335-P2 tube, A387Gr.2 plate. Welding conditions: preheating and channel (layer) temperature: 160~190℃; 3. Heat treatment: 690±15℃x1h heat treatment is carried out according to the standard requirements of welding materials.

AWS E8015-B1 type hand electrode for heat resistant steel is suitable for welding CrMo pearlite heat resistant steel (such as 12CrMo, etc.) and high temperature, high pressure pipeline, chemical container and other corresponding steel. Before welding, the electrode must be baked at about 350℃ for 1h, and then used with baking. Before welding, the weldment must be cleaned of rust, oil, water and other impurities.

Features

AWS E8015-B1 (R207) type hand welding electrode for heat resistant steel is a low sodium hydrogen type hand welding electrode, stable arc, less splash, good forming, easy desagging, X-Ray performance is excellent. Hand welding electrode is widely used in electric power, power engineering, petrochemical and other industries, the most commonly used Cr-Moh and Mn-Mo type heat resistant steel and Cr-Mo base multi-element alloy heat resistant steel. It is also necessary to adopt the method of preheating before positioning welding and formal welding for heat resistant steel welding. If the weldment is strong, it should be preheated as a whole. After welding, the weldment should be kept above the preheating temperature for several hours, and then slowly cooled.

Company & Factory

Product composition and mechanical properties introduction

Product composition and mechanical properties introduction

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Mo | P | S |

| GB/T RULES | 0.05-0.12 | 0.90 | 0.80 | 0.40-0.65 | 0.40-0.65 | 0.03 | 0.030 |

| AWS RULES | 0.05-0.12 | 0.90 | 0.80 | 0.40-0.65 | 0.40-0.65 | 0.03 | 0.030 |

| EXAMPLE VALUE | 0.078 | 0.72 | 0.35 | 0.56 | 0.53 | 0.016 | 0.01 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | |||||||||

| GB/T RULES | 460 | 550 | 690*1 | - | 17 | |||||||||

| AWS RULES | 460 | 550 | 690*1 | - | 19 | |||||||||

| EXAMPLE VALUE | 490 | 590 | 690*1 | 90/Normal temperature | 23 | |||||||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | ||||||

| ELECTRICITY (Amp) |

H/W | 80-110 | 100-130 | 130-180 | 170-210 | |||||

| O/W | 60-100 | 80-120 | 120-160 | - | ||||||

PACKING DETAILES:

| SEPCIFICATION | LENGTH | PCS/1KG | WEIGHT/1KG | |||

| 2.6mm | 300mm | 48PCS | 2KG | |||

| 3.2mm | 350mm | 27PCS | 5KG | |||

| 4.0mm | 350mm | 16PCS | 5KG | |||

| 5.0mm | 350mm | 12PCS | 5KG | |||

Typical Cases

Certificate

Product detail pictures:

Related Product Guide:

We usually continually offer you the most conscientious consumer services, along with the widest variety of designs and styles with finest materials. These initiatives include the availability of customized designs with speed and dispatch for China wholesale Welding Connection Supplier - AWS E8015-B1 Low-alloy steels Manual electrode Welding stuff – Honest Metal , The product will supply to all over the world, such as: Guyana, Amsterdam, South Africa, We've got won a good reputation among overseas and domestic clients. Adhering to the management tenet of credit oriented, customer first, high efficiency and mature services, we warmly welcome friends from all walks of life to cooperate with us.

This is a very professional wholesaler, we always come to their company for procurement, good quality and cheap.