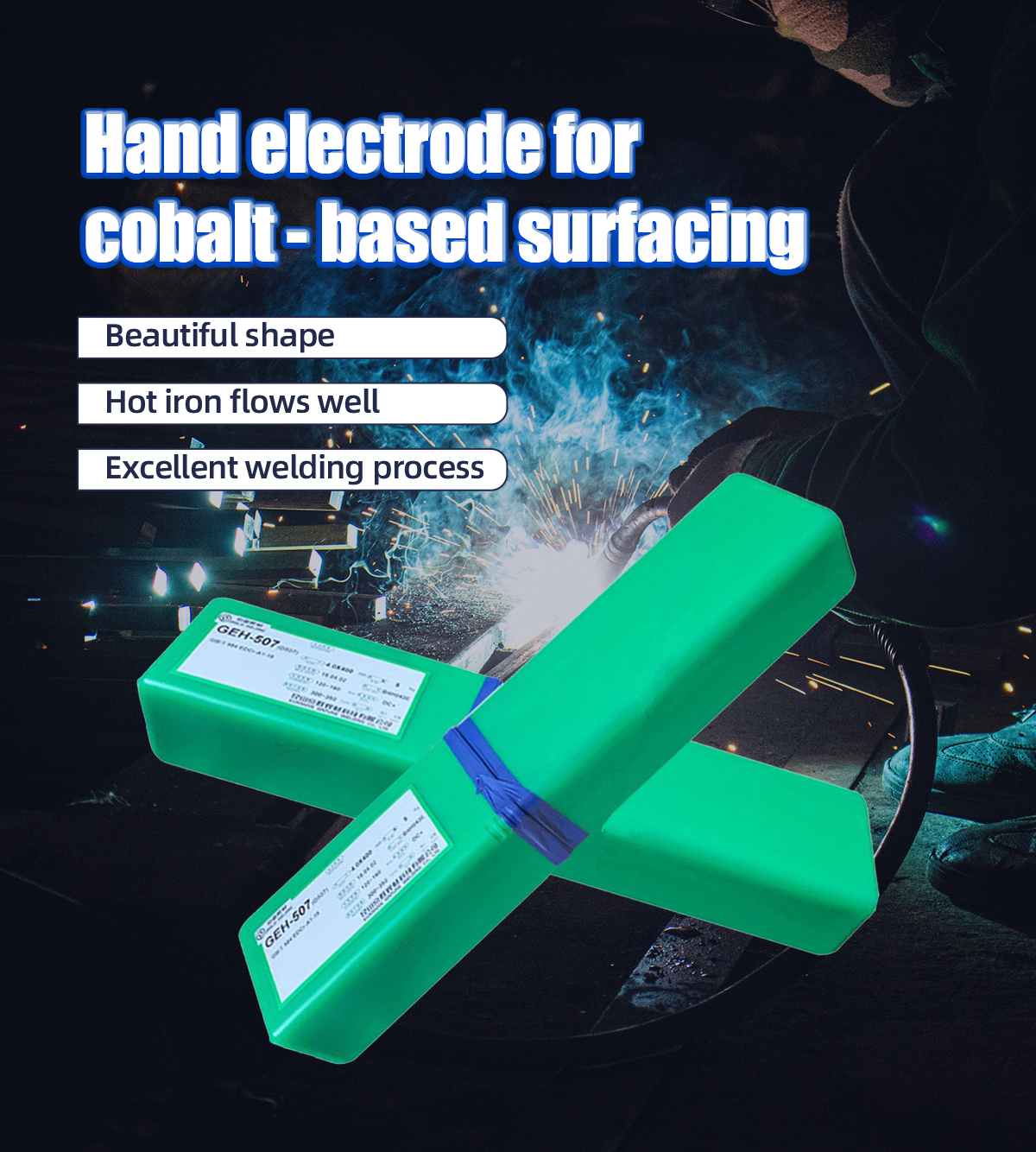

Cobalt alloys Manual electrode ECoCr-A Welding materials

Application

Used for surfacing high temperature and high pressure valves, hot shear blades, engine valves, turbine blades, etc.

Peculiarity

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | Fe | W | Co |

| GB/T RULES | 0.70-1.40 | 2.00 | 2.00 | 25.00-32.00 | - | - | 5 | 3.00-6.00 | Margin |

| AWS RULES | 0.7-1.4 | 2.00 | 2.00 | 25-32 | 3.00 | 1.00 | 5.00 | 3.0-6.0 | Margin |

| EXAMPLE VALUE | 1.03 | 1.28 | 1.11 | 30.1 | 2.4 | 0.1 | 3.650 | 4.42 | Margin |

WELD PASS HARDNESS:

Example value HRC=46

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 3.2*350 | 4.0*350 | 5.0*350 | ||||||||

| ELECTRICITY(Amp) | 120-160 | 140-190 | 150-210 | ||||||||

Titanium-calcium coated cobalt-based surfacing electrode should adopt DC reverse connection.

The surfacing metal can maintain good wear resistance and corrosion resistance at 650℃, and has strong impact resistance and cold and heat fatigue resistance.

It can be used to maintain good wear resistance and certain corrosion resistance when working at about 650℃, and it can have good performance in shock and hot and cold interlaced places.

Show details

Anti-corrosion

Wear-resisting

About us

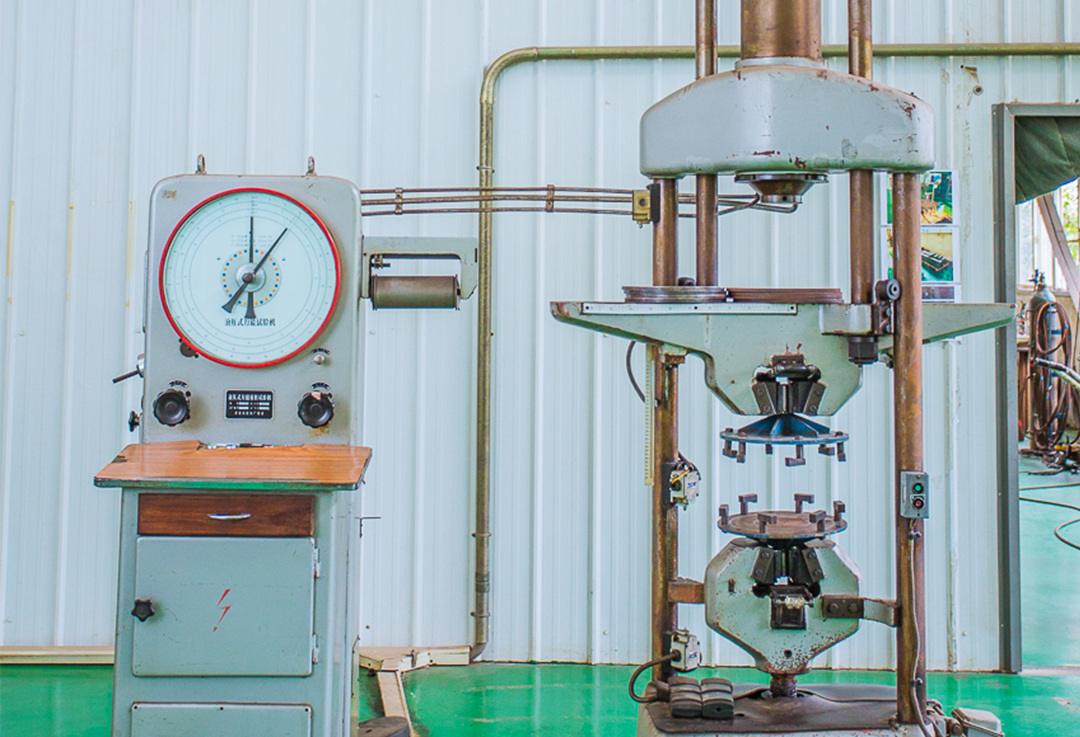

Factory fioor display

Application case

10 sets of 4000m³ spherical cans from Nanjing Jinling Petrochemical

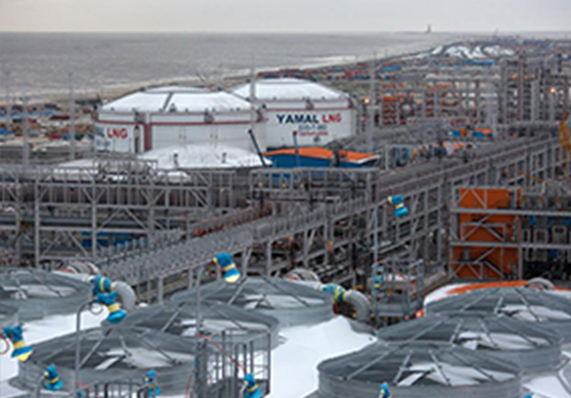

YAMAL LNG project

Actual factory shooting

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | Fe | W | Co |

| GB/T RULES | 0.70-1.40 | 2.00 | 2.00 | 25.00-32.00 | - | - | 5 | 3.00-6.00 | Margin |

| AWS RULES | 0.7-1.4 | 2.00 | 2.00 | 25-32 | 3.00 | 1.00 | 5.00 | 3.0-6.0 | Margin |

| EXAMPLE VALUE | 1.03 | 1.28 | 1.11 | 30.1 | 2.4 | 0.1 | 3.650 | 4.42 | Margin |

WELD PASS HARDNESS

Example value HRC=46

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 3.2*350 | 4.0*350 | 5.0*350 | ||||||||

| ELECTRICITY(Amp) | 120-160 | 140-190 | 150-210 | ||||||||

Write your message here and send it to us