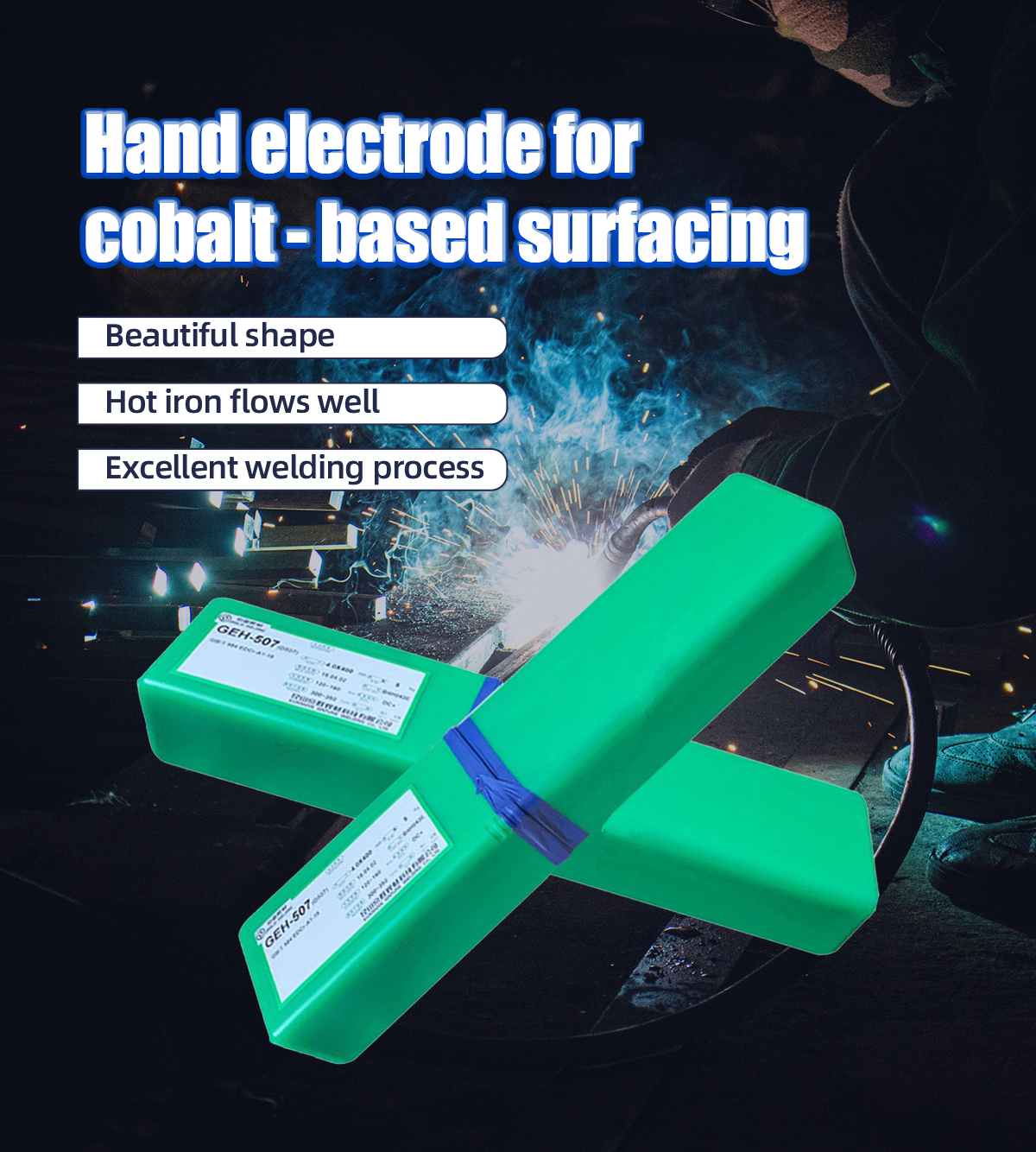

Cobalt Alloys Manual electrode EDCoCr-B Welding accessories

Application

Can be used for surfacing high temperature and high pressure valves, high pressure pump shaft sleeve and lining sleeve, chemical fiber equipment cutting edge, sawtooth, screw push rod, etc.

Peculiarity

Titanium-calcium coated cobalt-based surfacing electrode with cobalt-chromium-tungsten alloy as the core wire should be adopted.

Use DC reverse connection.

Surfacing metal can maintain good wear and corrosion resistance at 650℃.

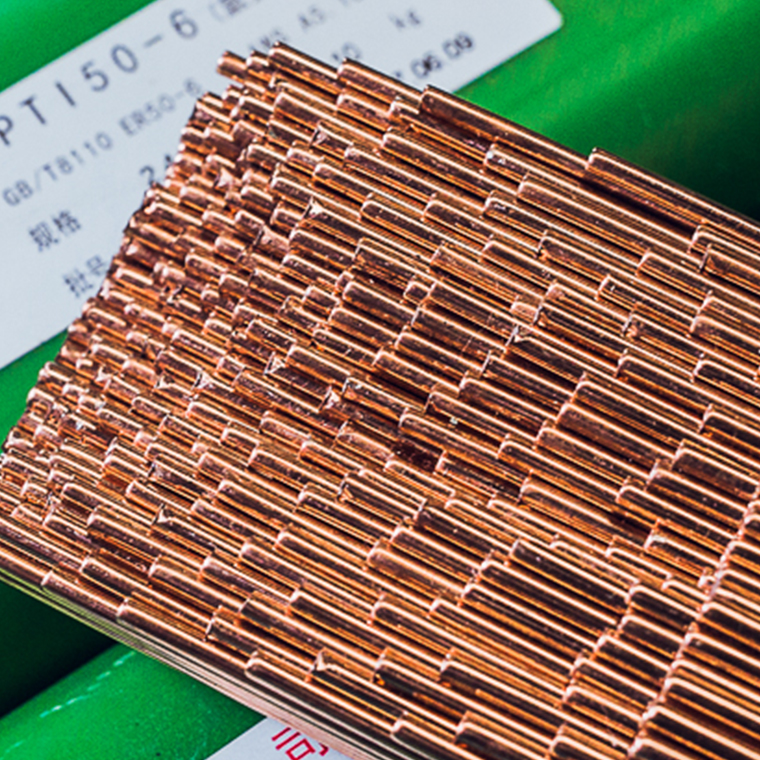

Show details

Beautiful shape

Beautiful shape

About us

Factory fioor display

Application case

Sino-russian Eastern Front

Hainan Huasheng phenol recovery tower

Actual factory shooting

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | Fe | W | Co |

| GB/T RULES | 1.00-1.70 | 2.00 | 2.00 | 25.00-32.00 | - | - | 5 | 7.00-10.00 | Margin |

| AWS RULES | 1.0-1.7 | 2.00 | 2.00 | 25-32 | 3.00 | 1.00 | 5.00 | 7.0-9.5 | Margin |

| EXAMPLE VALUE | 1.15 | 1.31 | 1.12 | 30.5 | 2.4 | 0.1 | 3.500 | 8.3 | Margin |

WELD PASS HARDNESS:

Example value HRC=46

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 3.2*350 | 4.0*350 | 5.0*350 | ||||||||

| ELECTRICITY(Amp) | 120-160 | 140-190 | 150-210 | ||||||||

Write your message here and send it to us