Have two types for Nickel alloy

Manual electrodes and Solid wire

Attention:The thermal expansion coefficient of copper is large, and large shrinkage stress occurs during solidification, resulting in cracks and deformation. Therefore, the assembly gap should be wide and the groove angle should be large. Multi-point temporary positioning spot welding can also be used. In order to obtain excellent welds, Before welding, the oxide, grease and other dirt on the edge to be welded should be removed

Copper alloys and Aluminum alloys

-

Copper alloys Manual electrode ECuNi Welding accessories

GB/T3670 E CuNi-B

AWS A5.6 ECuNi

Whatapp:+8613252436578

E-mail: sale@welding-honest.com

-

Copper alloys Solid wire ERCuNi Welding connection

GB/T9460 S Cu7158

AWS A5.7 ERCuNi

A5.7M ERCuNi

ISO 24373 S Cu 7158

Whatapp:+8613252436578

E-mail: sale@welding-honest.com

-

Aluminum alloys MIG ER5356 Welding accessories

GB/T10858 SAL5356

AWS A5.10 ER5356

ISO 18274:S Al 5356

Whatapp:+8613252436578

E-mail: sale@welding-honest.com

-

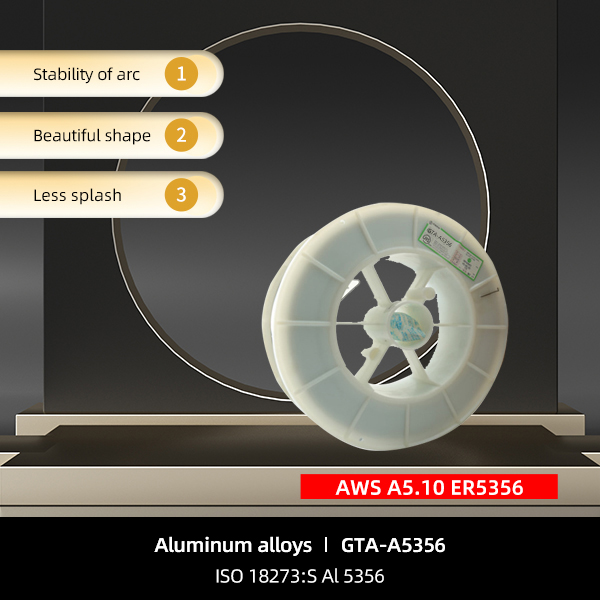

Aluminum alloys TIG ER5356 Welding jointing

GB/T10858 SAL5356

AWS A5.10 ER5356

ISO 18273:S Al 5356

Whatapp:+8613252436578

E-mail: sale@welding-honest.com