factory Outlets for Andeli Welding Rod Tungsten Electrodes 1.6/2.0/2.4/3.2mm Wt20/Wc20/Wl20/Wl15/Wz8/Wp

Often customer-oriented, and it’s our ultimate target to become not only probably the most reputable, trustable and honest provider, but also the partner for our customers for factory Outlets for Andeli Welding Rod Tungsten Electrodes 1.6/2.0/2.4/3.2mm Wt20/Wc20/Wl20/Wl15/Wz8/Wp, Welcome around the world customers to make contact with us for enterprise and long-term cooperation. We’re going to be your trustworthy partner and supplier of auto pieces and accessories in China.

Often customer-oriented, and it’s our ultimate target to become not only probably the most reputable, trustable and honest provider, but also the partner for our customers for China Wt20 Red Tungsten Electrode for TIG Welding and Red Tungsten Electrode for TIG Welding, We welcome you to visit our company & factory and our showroom displays various items that will meet your expectations. Meanwhile, it is convenient to visit our website. Our sales staff will try their best to supply you with the best services. If you have to have more information, be sure to do not hesitate to contact us via E-mail, fax or telephone.

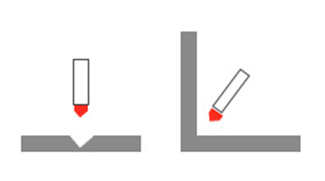

Application & Standard

GEH-547 hardface wear-resisting hand electrode is mainly used for surfacing and repairing worn parts of chemical equipment and various mechanical equipment. Such as slag crusher vulnerable parts (such as crusher hammer, hammer plate, counter plate), cement kiln unloading device (tray, spire, grate), brick machine reamer, mixer blades, dredging machine blades, power plant fan blades, steel mill blast furnace chute lining plate, roller, cone broken, charcoal machine and so on. The surfacing effect refers to the hardness, wear resistance and heat resistance of the welding layer, and its performance is related to the following factors:

1. Welding current size, arc length. Large current, long arc, alloying elements easy to burn, otherwise, favorable alloying elements transition. 2. Preheating temperature and slow cooling conditions determine the quality of the surfacing layer. 3. Different heat treatment methods can be used to obtain different hardness of some surfacing metals.

Features

GEH-547 is a low sodium hydrogen type chromium-nickel butt welding electrode, good operation, less splash, easy to slag, beautiful shape, easy to carry out mechanical processing; The strengthening of silicon enhances the hardness, abrasion resistance, corrosion resistance and oxidation resistance of the surfacing metal. The most common problem encountered in surfacing is cracking. The main methods to prevent cracking are as follows: 1. Preheat before welding, control the temperature between layers, slow cooling after welding; 2. 2. Heat treatment to eliminate stress after welding. 3, avoid multi-layer surfacing cracking, using low hydrogen type surfacing electrode. 4. Before welding, it needs to be dried at 300-350℃ for 1 hour; Need to remove the base material surface moisture, rust stains, oil, etc. Also need to pay attention to the way of arc and arc.

Company & Factory

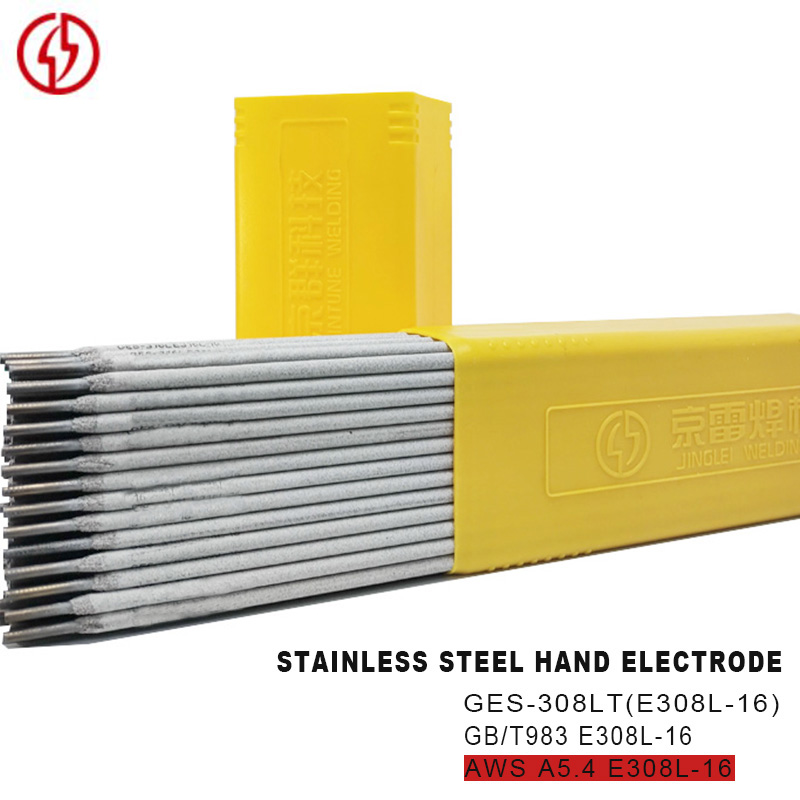

Product composition and mechanical properties introduction

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | P | S |

| GB/T RULES | 0.18 | 0.60-2.00 | 4.80-6.40 | 15.00-18.00 | 7.00-9.00 | 0.04 | 0.030 |

| AWS RULES | - | - | - | - | - | - | - |

| EXAMPLE VALUE | 0.05 | 1.26 | 5.34 | 16.8 | 7.78 | 0.028 | 0.006 |

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| ELECTRICITY (Amp) |

80-120 | 120-160 | 160-210 | |||||

TYPICAL CASES

Certificates

Often customer-oriented, and it’s our ultimate target to become not only probably the most reputable, trustable and honest provider, but also the partner for our customers for factory Outlets for Andeli Welding Rod Tungsten Electrodes 1.6/2.0/2.4/3.2mm Wt20/Wc20/Wl20/Wl15/Wz8/Wp, Welcome around the world customers to make contact with us for enterprise and long-term cooperation. We’re going to be your trustworthy partner and supplier of auto pieces and accessories in China.

factory Outlets for China Wt20 Red Tungsten Electrode for TIG Welding and Red Tungsten Electrode for TIG Welding, We welcome you to visit our company & factory and our showroom displays various items that will meet your expectations. Meanwhile, it is convenient to visit our website. Our sales staff will try their best to supply you with the best services. If you have to have more information, be sure to do not hesitate to contact us via E-mail, fax or telephone.

Product composition and mechanical properties introduction

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | P | S |

| GB/T RULES | 0.18 | 0.60-2.00 | 4.80-6.40 | 15.00-18.00 | 7.00-9.00 | 0.04 | 0.030 |

| AWS RULES | - | - | - | - | - | - | - |

| EXAMPLE VALUE | 0.05 | 1.26 | 5.34 | 16.8 | 7.78 | 0.028 | 0.006 |

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| ELECTRICITY (Amp) |

80-120 | 120-160 | 160-210 | |||||