Hard-facing D507Mo Manual electrode welding accessories

Application & Standard

1. It is used for intermetallic wear and welding of parts affected by water vapor, weak acid, cavitation, etc., such as valve sealing surface (below 510 °C), shaft, mixer pulp, screw conveyor sheet, etc

2. The standard we met: GB/T984 EDCr-A2-15

Features

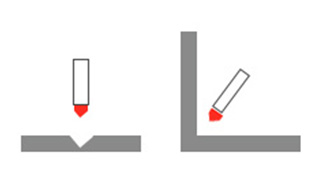

1. Low hydrogen sodium type high chromium steel surfacing electrode, good workability, less spatter, easy slag removal, beautiful forming, easy to machine operation.

2. The surfacing layer has air quenching characteristics, high medium temperature hardness, good thermal stability and corrosion resistance

Company & Factory

TYPICAL CASES

Certificates

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | W |

| GB/T RULES | 0.20 | - | - | 10.00-16.00 | 6.00 | 2.50 | 2.00 |

| AWS RULES | - | - | - | - | - | - | - |

| EXAMPLE VALUE | 0.1 | 0.35 | 1.1 | 12.8 | 2.00 | 1.41 | 0.02 |

WELDING HARDNESS

EXAMPLE:HRC=41

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 3.2*350 | 4.0*350 | 5..0*350 | ||||

| ELECTRICITY (Amp) |

80-120 | 120-160 | 160-210 |

Write your message here and send it to us