Hard-facing Manual electrode EDCr-A2-15 weld fabrication makings

Stability of arc

Beautiful shape

Splash very littel

Easy slagging

Good stomatal resistance

Stable peoperty

Application

It is used for surfacing of intermetallic wear and parts affected by water vapor, weak acid and cavitation, such as valve sealing surface (below 510℃), shaft, mixer slurry, screw conveyor blade, etc.

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | W |

| GB/T RULES | 0.20 | - | - | 10.00-16.00 | 6.00 | 2.50 | 2.00 |

| AWS RULES | - | - | - | - | - | - | - |

| EXAMPLE VALUE | 0.1 | 0.35 | 1.1 | 12.8 | 2 | 1.41 | 0.02 |

WELD PASS HARDNESS:

Example value HRC=40

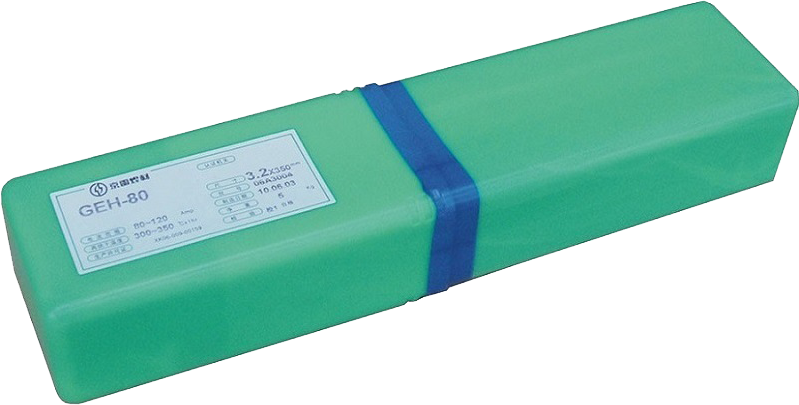

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 3.2*350 | 4.0*350 | 5.0*350 | ||||||||

| ELECTRICITY(Amp) | 80-120 | 120-160 | 160-210 | ||||||||

Low sodium hydrogen high chromium steel surfacing bar, good operation

Less splash, easy to remove slag, beautiful forming and easy machining.

The surfacing layer has the characteristics of air quenching, high medium temperature hardness, good thermal stability and corrosion resistance.

Ningbo Chengwei Metal Material Co., Ltd. is an international welding professional company with independent research and development, production, sales and management. It was established in 2020.

Zhejiang Satellite Energy 3× 60,000 m³ LPG storage tank

Cr-Mo steel series welding materials and electrode surfacing welding materials are widely used in petroleum refining equipment

GDS-2209/GXS-E330 tube surfacing site

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | W |

| GB/T RULES | 0.20 | - | - | 10.00-16.00 | 6.00 | 2.50 | 2.00 |

| AWS RULES | - | - | - | - | - | - | - |

| EXAMPLE VALUE | 0.1 | 0.35 | 1.1 | 12.8 | 2 | 1.41 | 0.02 |

WELD PASS HARDNESS:

Example value HRC=40

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 3.2*350 | 4.0*350 | 5.0*350 | ||||||||

| ELECTRICITY(Amp) | 80-120 | 120-160 | 160-210 | ||||||||