High Carbon steels ER70S-3 TIG Solid wire Welding connection

Application & Standard

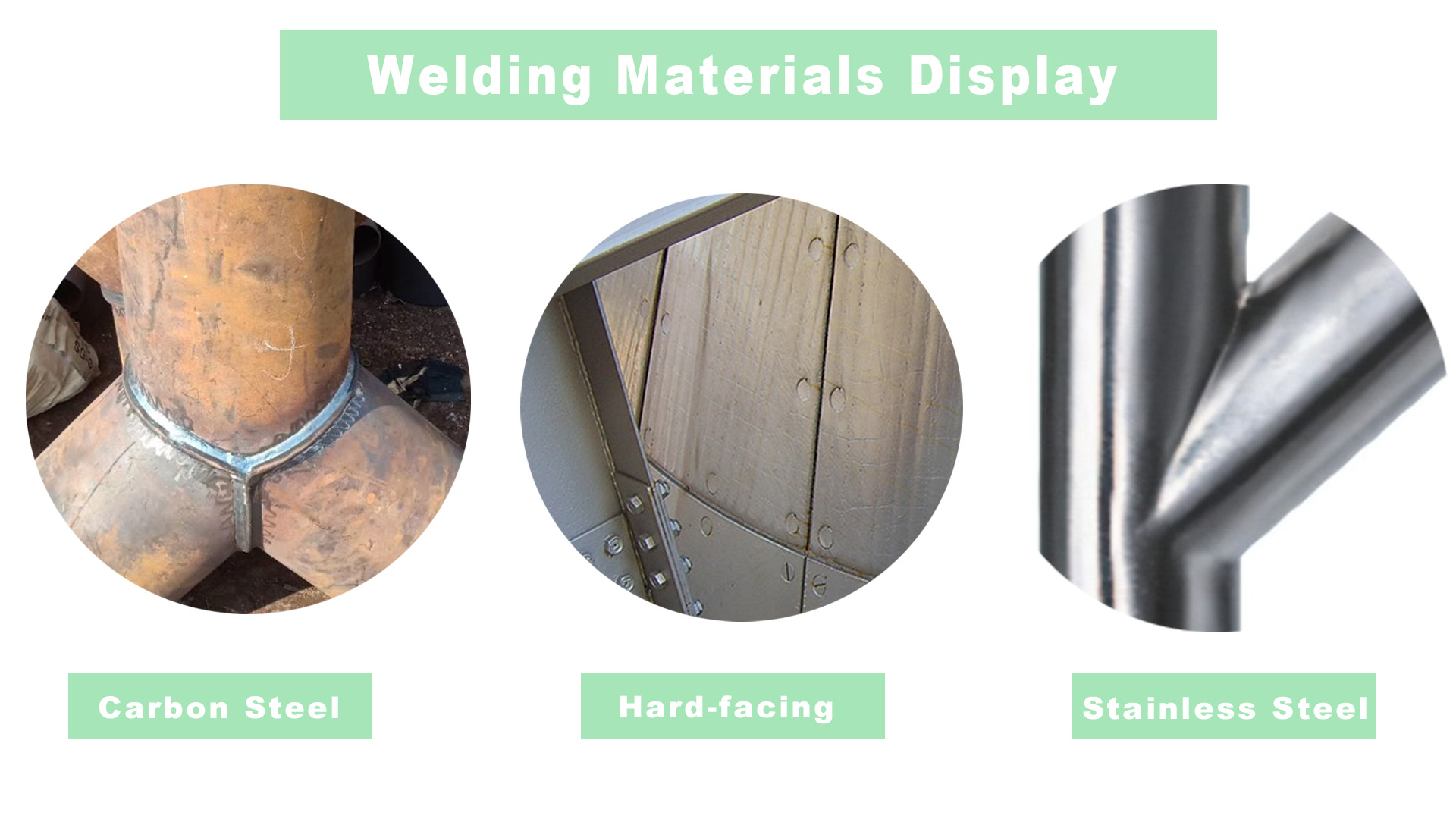

1. Suitable for boiler, chemical container, machinery, construction, shipbuilding and other industries, for higher requirements of low carbon steel and low alloy structural steel welding.

2. The standard we met: GB/T39280 W 49A/P 5 3 , AWS A5.18 ER70S-3 & A5.18M E49S-3, ISO636-A:W 42 4 2Si, ISO636-B: W 49A/P 4 3

Features

1.The wire feeding is smooth, the arc is stable, the forming is beautiful, the molten iron fluidity is good, the splash is less, has the excellent welding welding process performance.

2.The content of S and P is low in the fused metal, which has excellent plasticity, impact toughness and HIC/SSC resistance.

Company & Factory

TYPICAL CASES

Certificates

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu |

| GB/T RULES | 0.06-0.15 | 0.90-1.40 | 0.45-0.75 | 0.15 | 0.15 | 0.15 | 0.025 | 0.025 | 0.08 |

| AWS RULES | 0.06-0.15 | 0.90-1.40 | 0.45-0.75 | 0.15 | 0.15 | 0.15 | 0.025 | 0.025 | 0.08 |

| EXAMPLE VALUE | 0.078 | 1.090 | 0.67 | 0.01 | 0.01 | 0.01 | 0.005 | 0.003 | 0.23 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 390 | 490-670 | AW | 27/-50 | 18 | ||||

| AWS RULES | 400 | 490 | AW | 27/-20 | 22 | ||||

| EXAMPLE VALUE | 430 | 525 | AW | 265/-30 158/-50 | 29 | ||||

NOTE:

H/W: horizontal position welding. O/W: over-head position welding

CERTIFICATION AUTHORITY:ABS/BV/DNV/GL/CWB/CE