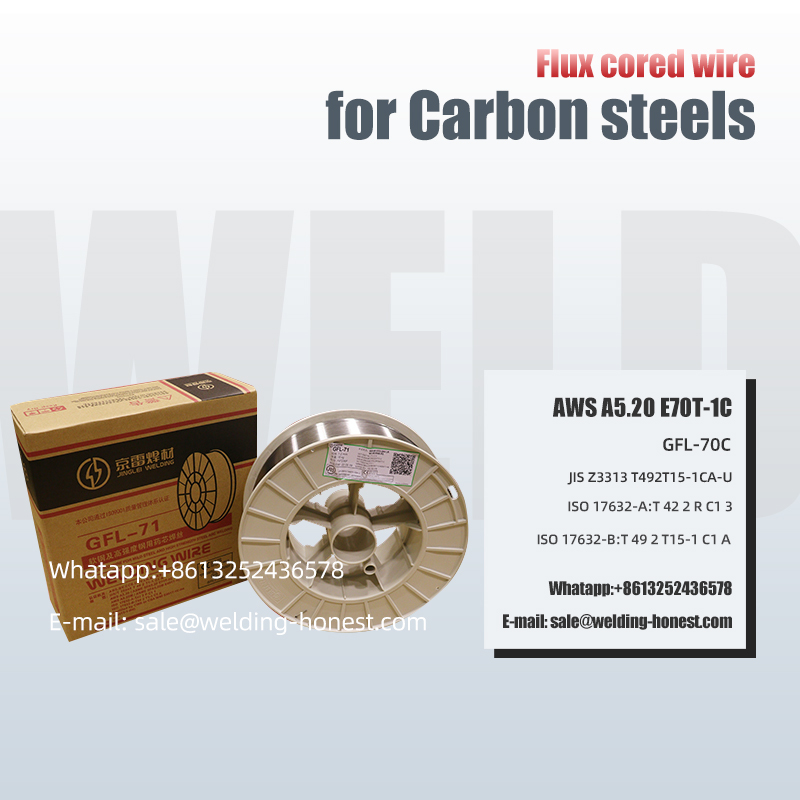

High Carbon steels Flux cored wire E71T-11 weld fabrication accessories

Application

Suitable for welding light structure of thin carbon steel and galvanized steel.

The standard we met: GB/T10045 T 49 Z T11 1 N A , AWS A5.20 E71T-11 & A5.20M E491T-11, ISO17632-A:T42 Z Y NO 1, ISO 17632-T49 Z T11-1 NO A.

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | AI |

| GB/T RULES | 0.30 | 2.00 | 0.90 | 0.20 | 0.50 | 0.30 | 0.030 | 0.030 | 2.00 |

| AWS RULES | 0.30 | 1.75 | 0.60 | 0.20 | 0.50 | 0.30 | 0.03 | 0.03 | 1.80 |

| EXAMPLE VALUE | 0.160 | 0.800 | 0.30 | 0.02 | 0.02 | 0.01 | 0.009 | 0.002 | 1.50 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | |||||

| GB/T RULES | 390 | 490-670 | AW | - | 18 | |||||

| AWS RULES | 390 | 490-670 | AW | - | 20 | |||||

| EXAMPLE VALUE | 420 | 570 | AW | - | 25 | |||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 0.8 | 0.9 | 1 | 1.2 | 1.6 | |||||

| VOLT | 14-19 | 16-20 | 18-25 | 18-25 | 20-26 | |||||

| AMP | 40-140 | 60-160 | 80-200 | 140-260 | 180-300 | |||||

| Length:MM | 10.00-15.00 | 10.00-15.00 | 10.00-15.00 | 10.00-15.00 | 10.00-15.00 | |||||

Peculiarity

Self-protecting flux-cored wire for high strength steel of class 490Mpa.

Easy to carry, and can carry the whole position of single pass and multi-pass welding.

Arc soft and stable, small splash.

Show details

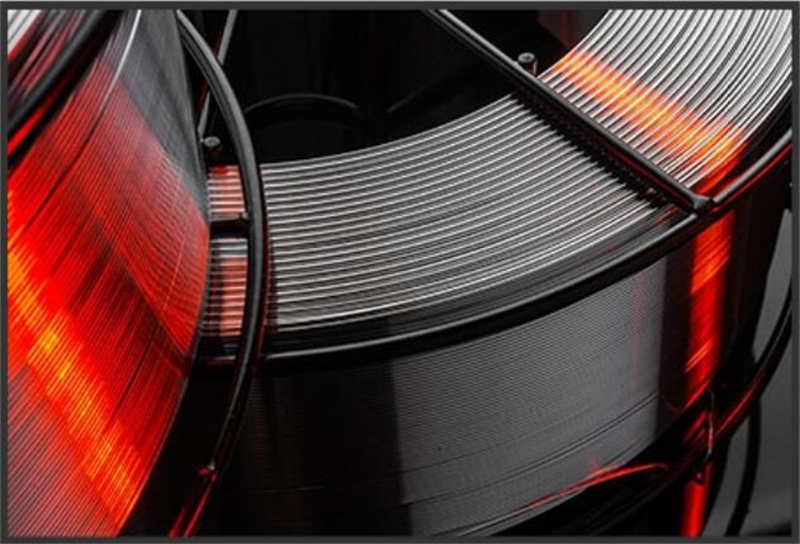

The arc is soft and stable

Small splash

About us

Factory fioor display

Application case

Upper core SG

Welding materials for aluminium alloys

Actual factory shooting

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | AI |

| GB/T RULES | 0.30 | 2.00 | 0.90 | 0.20 | 0.50 | 0.30 | 0.030 | 0.030 | 2.00 |

| AWS RULES | 0.30 | 1.75 | 0.60 | 0.20 | 0.50 | 0.30 | 0.03 | 0.03 | 1.80 |

| EXAMPLE VALUE | 0.160 | 0.800 | 0.30 | 0.02 | 0.02 | 0.01 | 0.009 | 0.002 | 1.50 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | |||||

| GB/T RULES | 390 | 490-670 | AW | - | 18 | |||||

| AWS RULES | 390 | 490-670 | AW | - | 20 | |||||

| EXAMPLE VALUE | 420 | 570 | AW | - | 25 | |||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 0.8 | 0.9 | 1 | 1.2 | 1.6 | |||||

| VOLT | 14-19 | 16-20 | 18-25 | 18-25 | 20-26 | |||||

| AMP | 40-140 | 60-160 | 80-200 | 140-260 | 180-300 | |||||

| Length:MM | 10.00-15.00 | 10.00-15.00 | 10.00-15.00 | 10.00-15.00 | 10.00-15.00 | |||||

Write your message here and send it to us