High Carbon steels Flux cored wire E71T-1C-J welding connection

Application

Suitable for offshore platform, port machinery. Ship, bridge, cryogenic vessel welding.

The standard we met: GB/T10045 T 49 4 T1-1 C1 A , AWS A5.20 E71T-1C-J & A5.20M E491T-1C-J , ISO17632-A:T42 4 P C1 1, ISO 17632-T49 4 T1-A C1 A JIS Z3313 T494T1-1CA-U.

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T RULES | 0.18 | 2.00 | 0.90 | 0.20 | 0.50 | 0.30 | 0.030 | 0.030 | 0.08 |

| AWS RULES | 0.12 | 1.75 | 0.90 | 0.20 | 0.50 | 0.30 | 0.030 | 0.030 | 0.08 |

| EXAMPLE VALUE | 0.034 | 1.240 | 0.37 | 0.03 | 0.45 | 0.01 | 0.011 | 0.005 | 0.01 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 390 | 490-670 | AW | 27/-40 | 18 | ||||

| AWS RULES | 390 | 490-670 | AW | 27/-40 | 22 | ||||

| EXAMPLE VALUE | 505 | 560 | AW | 118/-40 | 28 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 1.2 | 1.4 | 1.6 | ||||

| VOLT | 23-32 | 24-36 | 25-40 | ||||

| AMP | 150-300 | 170-360 | 200-400 | ||||

| MM | 15-20 | 15-20 | 18-25 | ||||

| L/MIN | 15-25 | 15-25 | 15-25 |

Peculiarity

The arc is soft and stable, less splashing, beautiful forming.

-40℃ impact performance is excellent, CTOD performance is stable.

Good desagging, less soot, and has excellent welding process performance.

Show details

Soft and stable

Beautiful shape

About us

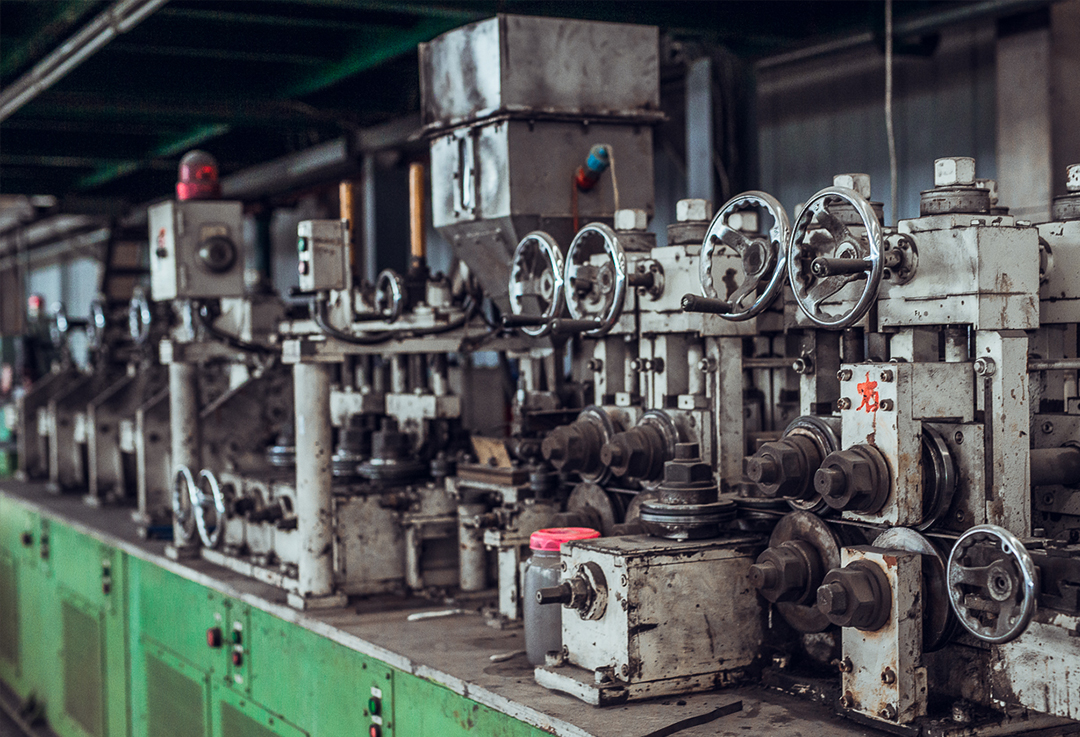

Factory fioor display

Application case

9000-ton chemical tanker

CJ50 jack-up rig

Actual factory shooting

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T RULES | 0.18 | 2.00 | 0.90 | 0.20 | 0.50 | 0.30 | 0.030 | 0.030 | 0.08 |

| AWS RULES | 0.12 | 1.75 | 0.90 | 0.20 | 0.50 | 0.30 | 0.030 | 0.030 | 0.08 |

| EXAMPLE VALUE | 0.034 | 1.240 | 0.37 | 0.03 | 0.45 | 0.01 | 0.011 | 0.005 | 0.01 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 390 | 490-670 | AW | 27/-40 | 18 | ||||

| AWS RULES | 390 | 490-670 | AW | 27/-40 | 22 | ||||

| EXAMPLE VALUE | 505 | 560 | AW | 118/-40 | 28 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 1.2 | 1.4 | 1.6 | ||||

| VOLT | 23-32 | 24-36 | 25-40 | ||||

| AMP | 150-300 | 170-360 | 200-400 | ||||

| MM | 15-20 | 15-20 | 18-25 | ||||

| L/MIN | 15-25 | 15-25 | 15-25 |

Write your message here and send it to us