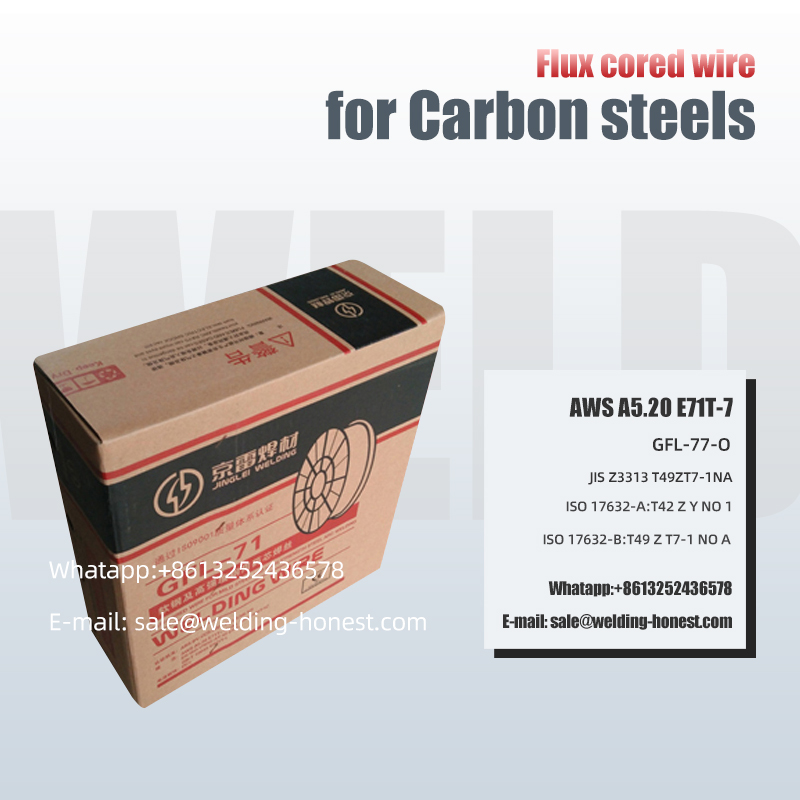

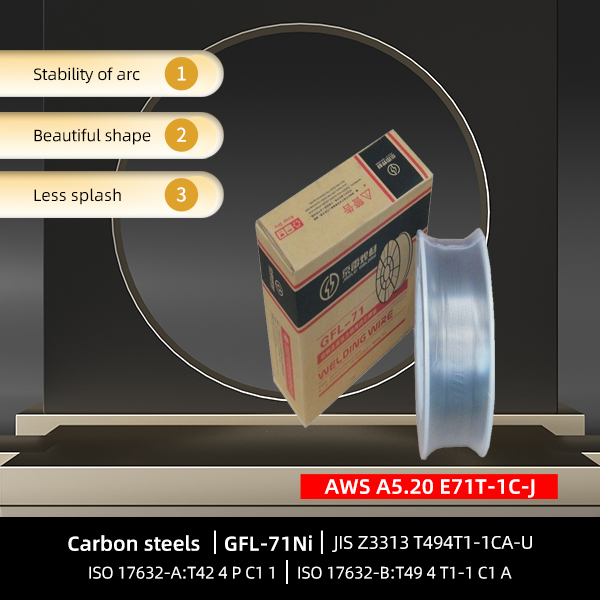

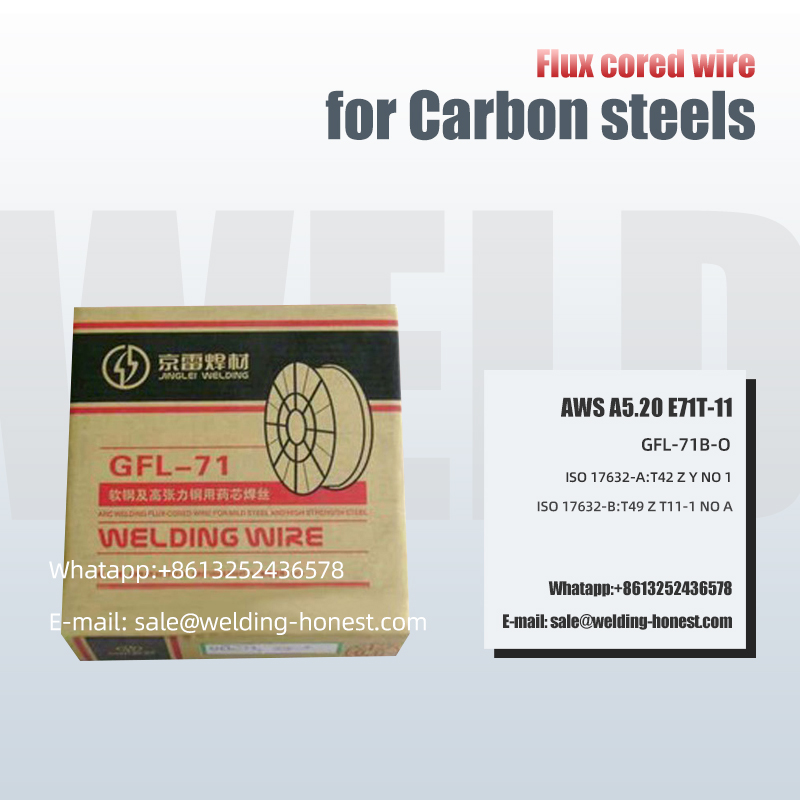

High Carbon steels Flux cored wire E71T-7 Soldering connection

Suitable for civil construction, steel frame, steel pipe hook, chimney, pipe and other structural parts of outdoor welding.

The standard we met: GB/T10045 T 49 Z T7-1 N A , AWS A5.20 E71T-A & A5.20M E491T-7, ISO17632-A:T42 Z Y NO 1, ISO 17632-B:T49 Z T7-1 NO A, JIS Z3313 T49ZT7-1NA.

What are the

characieristics?

●The melting drop is fine melting drop transition or spray transition.

●With good penetration depth, good wetting degree and fast melting filling speed.

●Low sulfur content of weld metal, good crack resistance.

●Small diameter welding wire can be used for full position welding.

Product Parameter

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | AI |

| GB/T RULES | 0.30 | 2.00 | 0.90 | 0.20 | 0.50 | 0.30 | 0.030 | 0.030 | 2.00 |

| AWS RULES | 0.30 | 1.75 | 0.60 | 0.20 | 0.50 | 0.30 | 0.030 | 0.030 | 1.80 |

| EXAMPLE VALUE | 0.250 | 0.500 | 0.10 | 0.02 | 0.01 | 0.01 | 0.01 | 0.003 | 1.5 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 390 | 490-670 | AW | - | 18 | ||||

| AWS RULES | 390 | 490-670 | AW | - | 22 | ||||

| EXAMPLE VALUE | 432 | 600 | AW | - | 27 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 1.6 | 2 | 2.4 | ||||

| VOLT | 22-30 | 24-30 | 26-34 | ||||

| AMP | 160-300 | 200-350 | 250-400 | ||||

| LENGTH:MM | 20-30 | 25-35 | 30-40 |

Look at the way

we transport

●Motor transport

●Shipping

Look at

our warenouse

The projects

we are involve in

●Shanghai Morimatsu Storage tank

●China-russia eastern front

Our products

to the world

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | AI |

| GB/T RULES | 0.30 | 2.00 | 0.90 | 0.20 | 0.50 | 0.30 | 0.030 | 0.030 | 2.00 |

| AWS RULES | 0.30 | 1.75 | 0.60 | 0.20 | 0.50 | 0.30 | 0.030 | 0.030 | 1.80 |

| EXAMPLE VALUE | 0.250 | 0.500 | 0.10 | 0.02 | 0.01 | 0.01 | 0.01 | 0.003 | 1.5 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 390 | 490-670 | AW | - | 18 | ||||

| AWS RULES | 390 | 490-670 | AW | - | 22 | ||||

| EXAMPLE VALUE | 432 | 600 | AW | - | 27 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 1.6 | 2 | 2.4 | ||||

| VOLT | 22-30 | 24-30 | 26-34 | ||||

| AMP | 160-300 | 200-350 | 250-400 | ||||

| LENGTH:MM | 20-30 | 25-35 | 30-40 |

Write your message here and send it to us