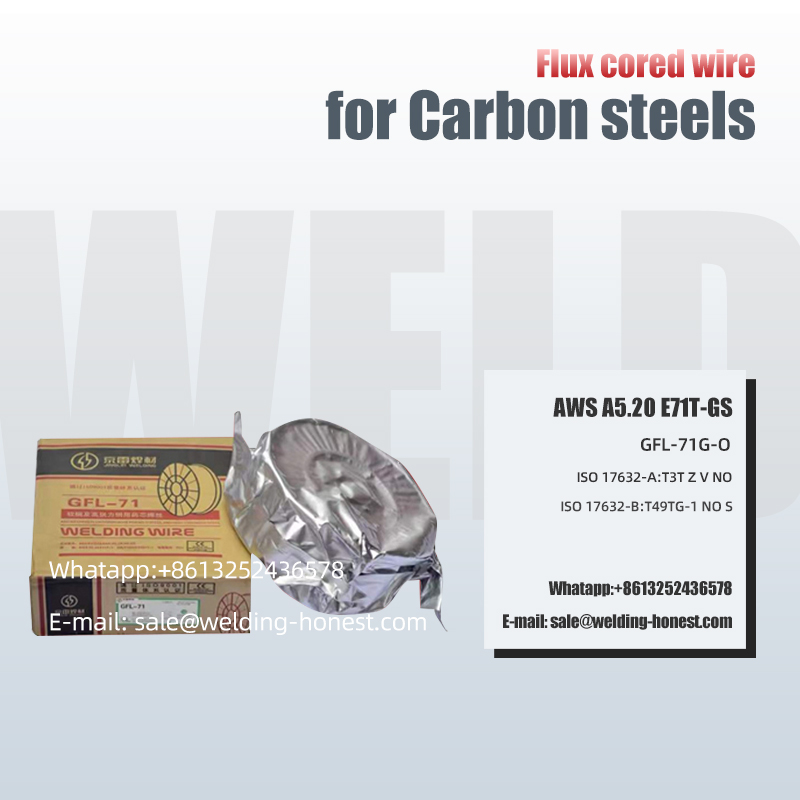

High Carbon steels Flux cored wire E71T-GS Soldering data

Suitable for welding light structure of thin carbon steel and galvanized steel.

The standard we met: GB/T10045 T49 TG-1 N S , AWS A5.20 E71T-GS & A5.20M E491T-GS, ISO17632-A:T3T Z V NO, ISO 17632-B:T49TG-1 NO S, JIS Z3313 T49T1-1CA-U.

What are the

characieristics?

●Self-protecting flux-cored wire for high strength steel of class 490Mpa.

●Easy to carry, and can carry the whole position of single pass and multi-pass welding.

●Arc soft and stable

●Small splash

Product Parameter

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T RULES | - | - | - | - | - | - | - | - | - |

| AWS RULES | - | - | - | - | - | - | - | - | - |

| EXAMPLE VALUE | 0.095 | 0.950 | 0.02 | 0.02 | 0.02 | 0.01 | 0.010 | 0.002 | 2.50 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | |||||

| GB/T RULES | - | 490 | AW | - | - | |||||

| AWS RULES | - | 490 | AW | - | - | |||||

| EXAMPLE VALUE | - | 210 | AW | - | - | |||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 0.8 | 0.9 | 1 | 1.2 | 1.6 | |||||

| VOLT | 14-19 | 16-20 | 18-25 | 18-525 | 20-26 | |||||

| AMP | 40-140 | 60-160 | 80-200 | 140-260 | 180-300 | |||||

| MM | 10.00-15.00 | 10.00-15.00 | 10.00-15.00 | 10.00-15.00 | 10.00-15.00 | |||||

Look at the way

we transport

●Motor transport

●Shipping

Look at

our warenouse

The projects

we are involve in

●Nanjing Jinling Petrochemical 10 4000m³ spherical cans

●180,000 tons Capesize bulk carrier

Our products

to the world

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T RULES | - | - | - | - | - | - | - | - | - |

| AWS RULES | - | - | - | - | - | - | - | - | - |

| EXAMPLE VALUE | 0.095 | 0.950 | 0.02 | 0.02 | 0.02 | 0.01 | 0.010 | 0.002 | 2.50 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | |||||

| GB/T RULES | - | 490 | AW | - | - | |||||

| AWS RULES | - | 490 | AW | - | - | |||||

| EXAMPLE VALUE | - | 210 | AW | - | - | |||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 0.8 | 0.9 | 1 | 1.2 | 1.6 | |||||

| VOLT | 14-19 | 16-20 | 18-25 | 18-525 | 20-26 | |||||

| AMP | 40-140 | 60-160 | 80-200 | 140-260 | 180-300 | |||||

| MM | 10.00-15.00 | 10.00-15.00 | 10.00-15.00 | 10.00-15.00 | 10.00-15.00 | |||||

Write your message here and send it to us