High Carbon Steels Manual Electrode E10018M liquefied natural gas carrier electrode

Suitable for welding THE corresponding strength grade of low alloy high strength steel structure, such as construction machinery, etc.

The standard we met: GB/T32533 E6918-N3M2, AWS A5.5 E10018M & A5.5M E6918M, ISO18275-A:, ISO 18275-B: E6918-N3M2 A.

What are the

characieristics?

●Iron powder low hydrogen potassium hand electrode, high efficiency.

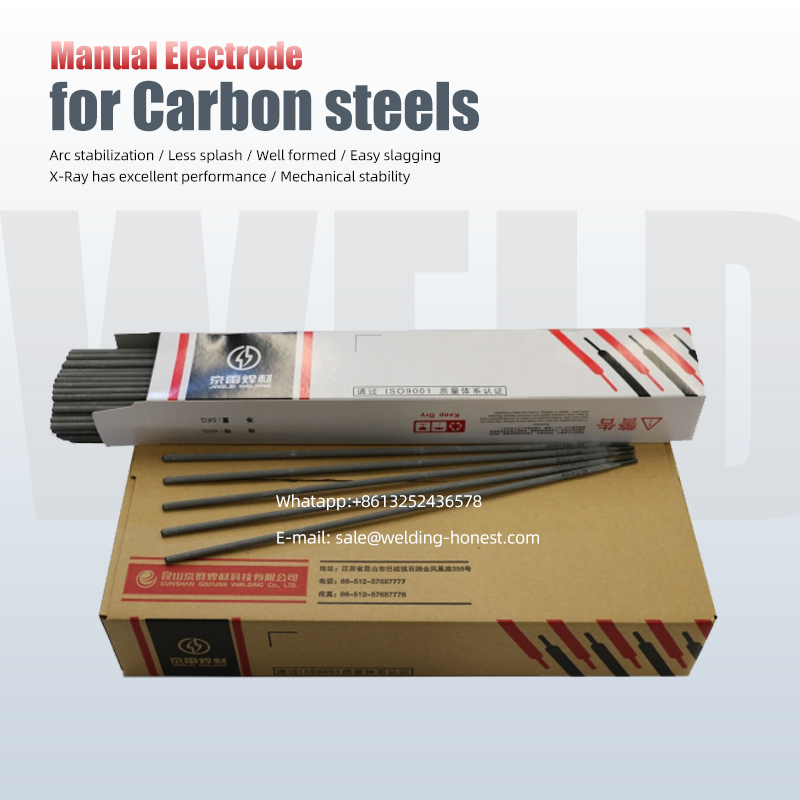

●Stable arc, small splash, good molding.

●Easy desagging, X-ray performance is good.

●Stable mechanical properties.

Product Parameter

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T RULES | 0.10 | 0.75-1.70 | 0.60 | 0.35 | 1.40-2.10 | 0.25-0.5 | 0.030 | 0.030 | 0.05 |

| AWS RULES | 0.10 | 0.75-1.70 | 0.60 | 0.35 | 1.40-2.10 | 0.25-0.5 | 0.030 | 0.030 | 0.05 |

| EXAMPLE VALUE | 0.075 | 1.54 | 0.33 | 0.02 | 1.85 | 0.38 | 0.010 | 0.006 | 0.002 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 610-690 | 690 | AW | 27/-50 | 18 | ||||

| AWS RULES | 610-690 | 690 | AW | 27/-50 | 20 | ||||

| EXAMPLE VALUE | 655 | 735 | AW | 85/-50 | 23 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| ELECTRICITY (Amp) |

H/W | 80-110 | 100-130 | 130-180 | 180-230 | ||||

| O/W | 50-80 | 90-120 | 130-160 | - | |||||

Look at the way

we transport

●Motor transport

●Shipping

Lookat

our warenouse

The projects

we are involve in

●400,000 tons ore carrier

●3,000-meter deepwater semi-submersible drilling platform "Haiyang Shiyou 981"

Our products

to the world

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T RULES | 0.10 | 0.75-1.70 | 0.60 | 0.35 | 1.40-2.10 | 0.25-0.5 | 0.030 | 0.030 | 0.05 |

| AWS RULES | 0.10 | 0.75-1.70 | 0.60 | 0.35 | 1.40-2.10 | 0.25-0.5 | 0.030 | 0.030 | 0.05 |

| EXAMPLE VALUE | 0.075 | 1.54 | 0.33 | 0.02 | 1.85 | 0.38 | 0.010 | 0.006 | 0.002 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 610-690 | 690 | AW | 27/-50 | 18 | ||||

| AWS RULES | 610-690 | 690 | AW | 27/-50 | 20 | ||||

| EXAMPLE VALUE | 655 | 735 | AW | 85/-50 | 23 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| ELECTRICITY (Amp) |

H/W | 80-110 | 100-130 | 130-180 | 180-230 | ||||

| O/W | 50-80 | 90-120 | 130-160 | - | |||||

Write your message here and send it to us