High Carbon steels Manual electrode E10018M weld fabrication makings

Application

Suitable for welding THE corresponding strength grade of low alloy high strength steel structure, such as construction machinery, etc.

The standard we met: GB/T32533 E6918-N3M2, AWS A5.5 E10018M & A5.5M E6918M, ISO18275-A:, ISO 18275-B: E6918-N3M2 A.

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T RULES | 0.10 | 0.75-1.70 | 0.60 | 0.35 | 1.40-2.10 | 0.25-0.5 | 0.030 | 0.030 | 0.05 |

| AWS RULES | 0.10 | 0.75-1.70 | 0.60 | 0.35 | 1.40-2.10 | 0.25-0.5 | 0.030 | 0.030 | 0.05 |

| EXAMPLE VALUE | 0.075 | 1.54 | 0.33 | 0.02 | 1.85 | 0.38 | 0.010 | 0.006 | 0.002 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 610-690 | 690 | AW | 27/-50 | 18 | ||||

| AWS RULES | 610-690 | 690 | AW | 27/-50 | 20 | ||||

| EXAMPLE VALUE | 655 | 735 | AW | 85/-50 | 23 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| ELECTRICITY (Amp) |

H/W | 80-110 | 100-130 | 130-180 | 180-230 | ||||

| O/W | 50-80 | 90-120 | 130-160 | - | |||||

Peculiarity

Iron powder low hydrogen potassium hand electrode, high efficiency.

Stable arc, small splash, good molding, easy desagging.

X-ray performance is good, stable mechanical properties.

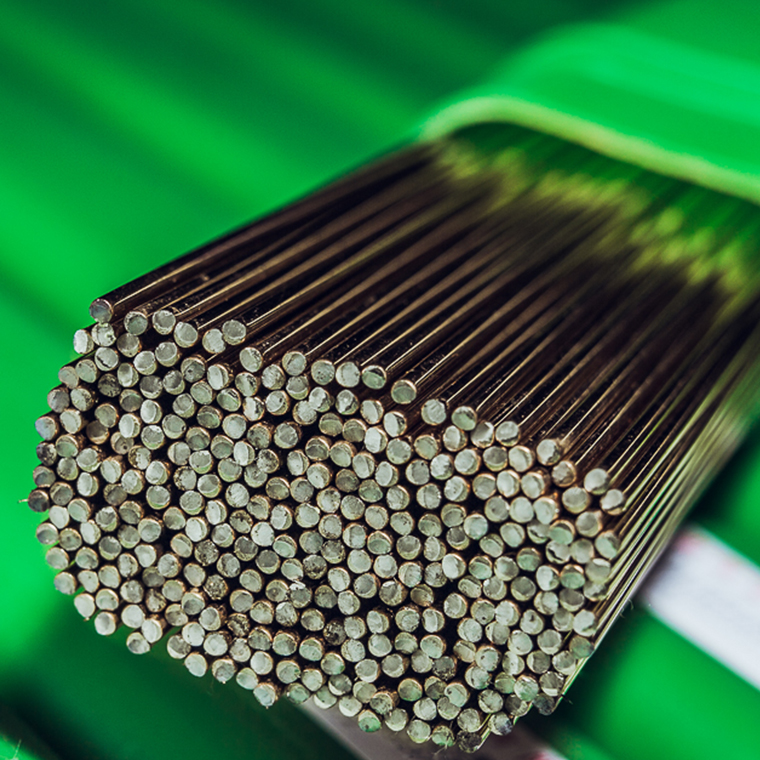

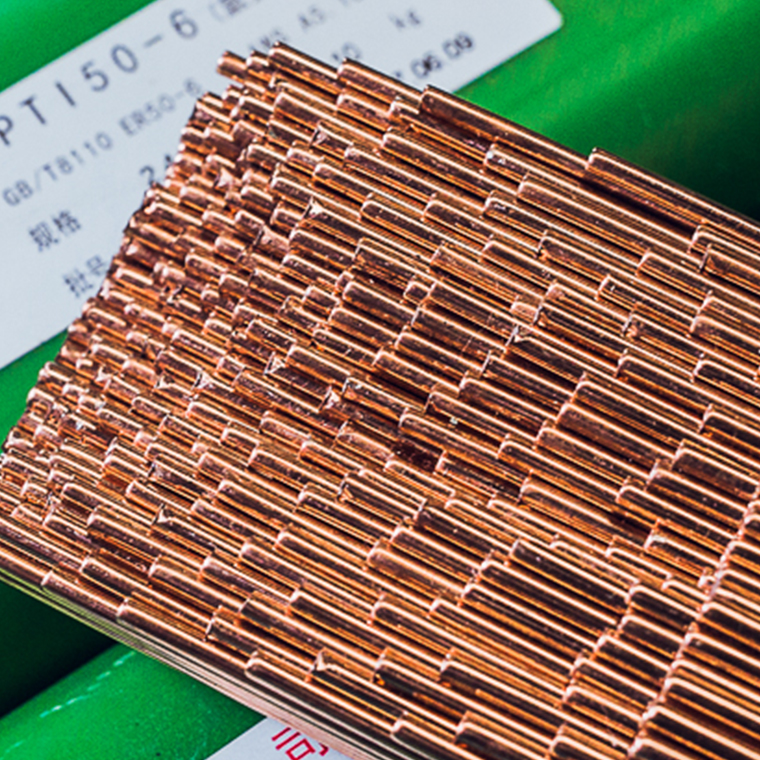

Show details

Beautiful shape

Beautiful shape

About us

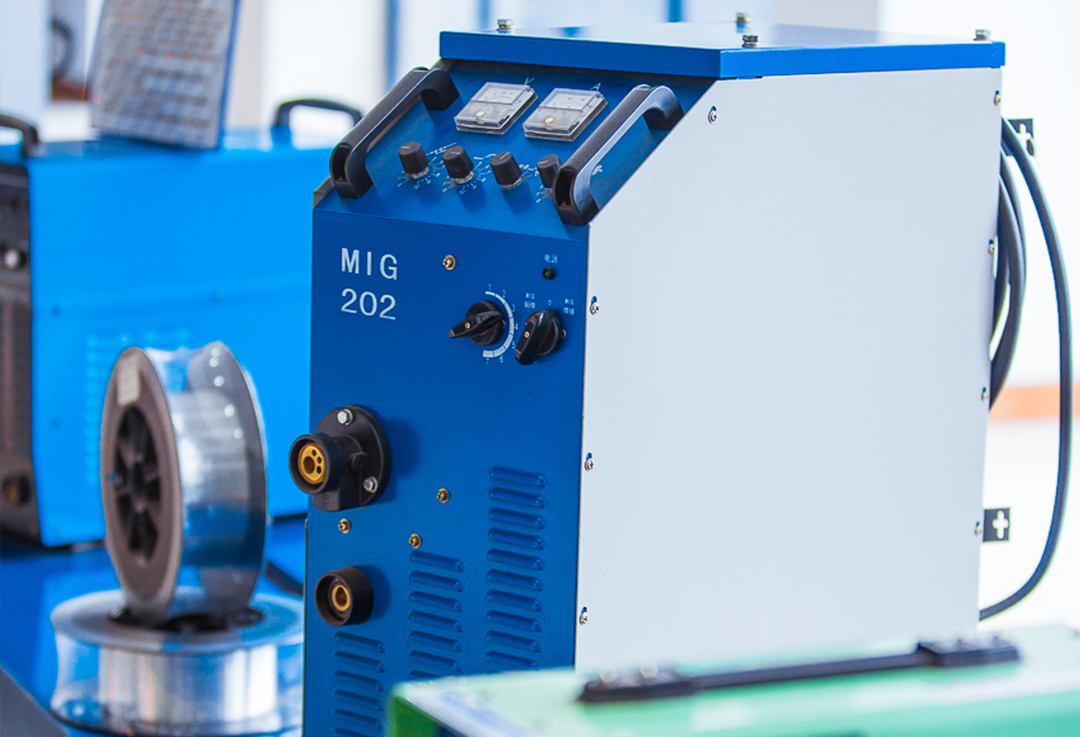

Factory fioor display

Application case

300,000-ton offshore Floating Production and Storage Tanker (FPSO)

308,000 tons VLCC crude oil ship

Actual factory shooting

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T RULES | 0.10 | 0.75-1.70 | 0.60 | 0.35 | 1.40-2.10 | 0.25-0.5 | 0.030 | 0.030 | 0.05 |

| AWS RULES | 0.10 | 0.75-1.70 | 0.60 | 0.35 | 1.40-2.10 | 0.25-0.5 | 0.030 | 0.030 | 0.05 |

| EXAMPLE VALUE | 0.075 | 1.54 | 0.33 | 0.02 | 1.85 | 0.38 | 0.010 | 0.006 | 0.002 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 610-690 | 690 | AW | 27/-50 | 18 | ||||

| AWS RULES | 610-690 | 690 | AW | 27/-50 | 20 | ||||

| EXAMPLE VALUE | 655 | 735 | AW | 85/-50 | 23 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| ELECTRICITY (Amp) |

H/W | 80-110 | 100-130 | 130-180 | 180-230 | ||||

| O/W | 50-80 | 90-120 | 130-160 | - | |||||

Write your message here and send it to us