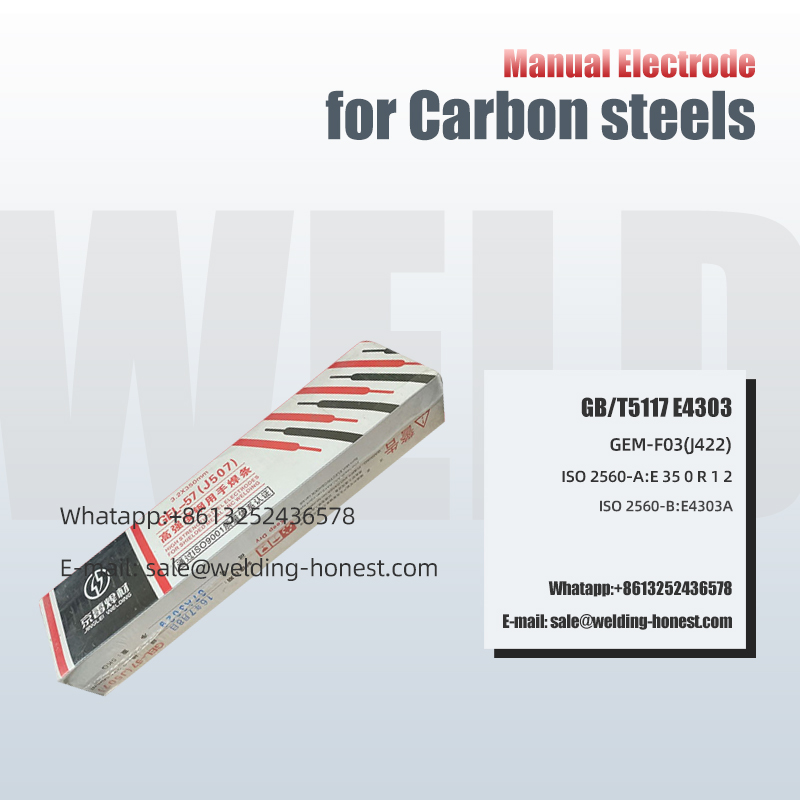

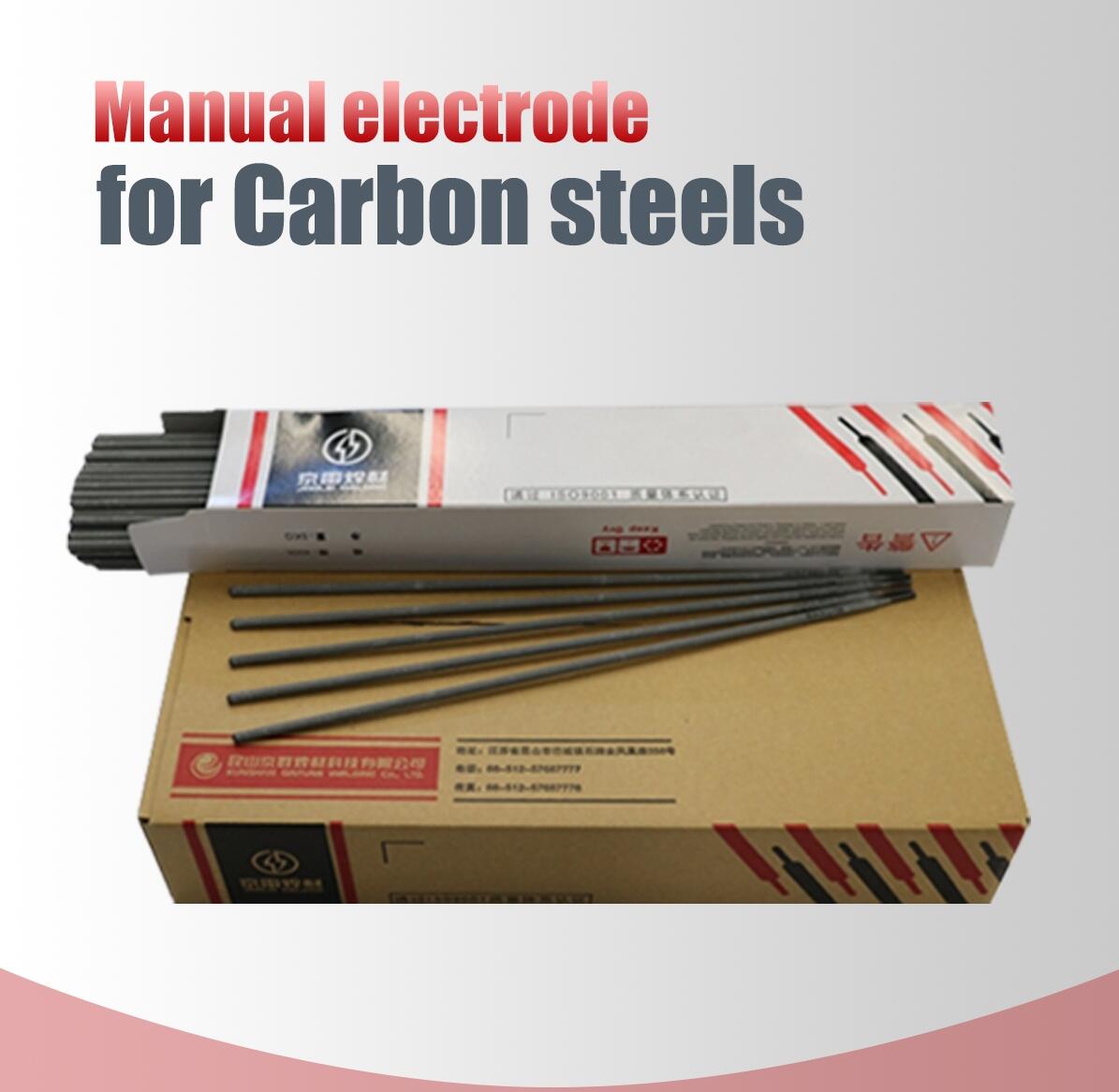

High Carbon steels Manual electrode E4303 metal Jointing stuff

Welding ordinary strength of low carbon steel structure and low strength grade of low alloy steel.

The standard we met: GB/T5117 E4303, AWS, ISO2560-A:E 35 0 R 1 2, ISO 2560-B: E4303A, JIS Z3211 E4303.

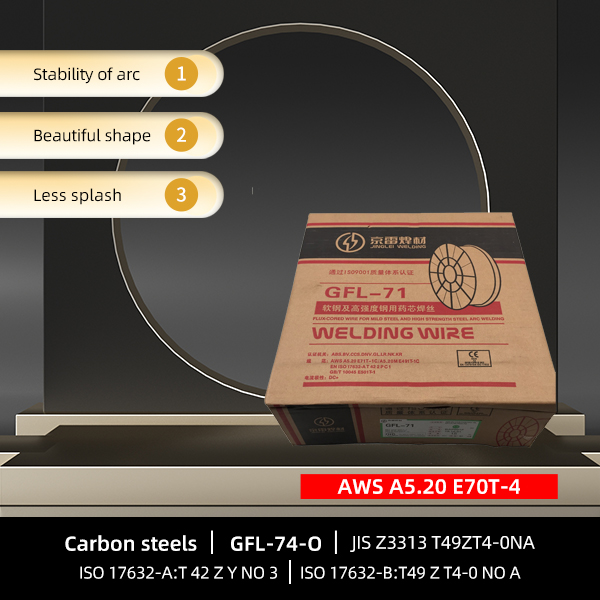

What are the

characieristics?

●Titanium calcium type c hemical skin carbon steel electrode.

●Stable arc, good slag fluidity

●Easy slag removal

●Small splash, beautiful shape.

Product Parameter

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T RULES | 0.20 | 1.20 | 1.00 | 0.20 | 0.30 | 0.30 | 0.040 | 0.035 | 0.080 |

| AWS RULES | - | - | - | - | - | - | - | - | - |

| EXAMPLE VALUE | 0.076 | 0.50 | 0.38 | 0.025 | 0.01 | 0.028 | 0.016 | 0.010 | 0.008 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 330 | 430 | AW | 27/0 | 20 | ||||

| AWS RULES | - | - | AW | - | - | ||||

| EXAMPLE VALUE | 468 | 538 | AW | 59/0 | 23.5 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| ELECTRICITY (Amp) |

H/W | 80-120 | 90-140 | 150-190 | 180-240 | ||||

| O/W | 50-80 | 90-120 | 130-160 | - | |||||

Look at the way

we transport

●Motor transport

●Shipping

Look at

our warenouse

The projects

we are involve in

●Safety injection tank

●Xinjiang Kela 2 Central treatment plant project

Our products

to the world

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T RULES | 0.20 | 1.20 | 1.00 | 0.20 | 0.30 | 0.30 | 0.040 | 0.035 | 0.080 |

| AWS RULES | - | - | - | - | - | - | - | - | - |

| EXAMPLE VALUE | 0.076 | 0.50 | 0.38 | 0.025 | 0.01 | 0.028 | 0.016 | 0.010 | 0.008 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 330 | 430 | AW | 27/0 | 20 | ||||

| AWS RULES | - | - | AW | - | - | ||||

| EXAMPLE VALUE | 468 | 538 | AW | 59/0 | 23.5 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| ELECTRICITY (Amp) |

H/W | 80-120 | 90-140 | 150-190 | 180-240 | ||||

| O/W | 50-80 | 90-120 | 130-160 | - | |||||

Write your message here and send it to us