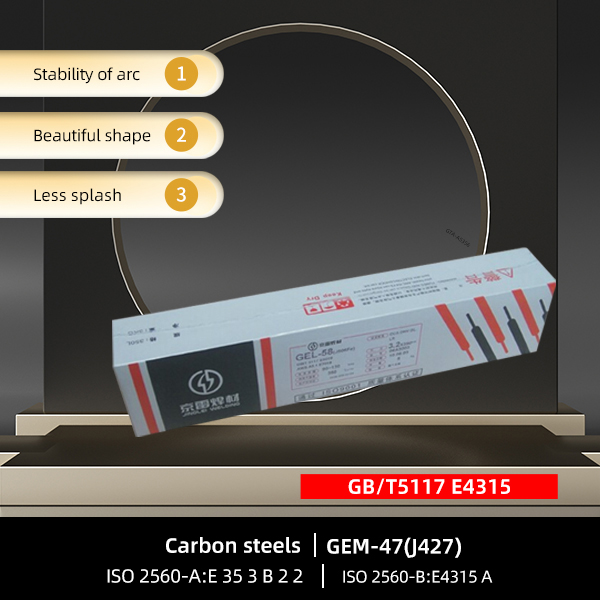

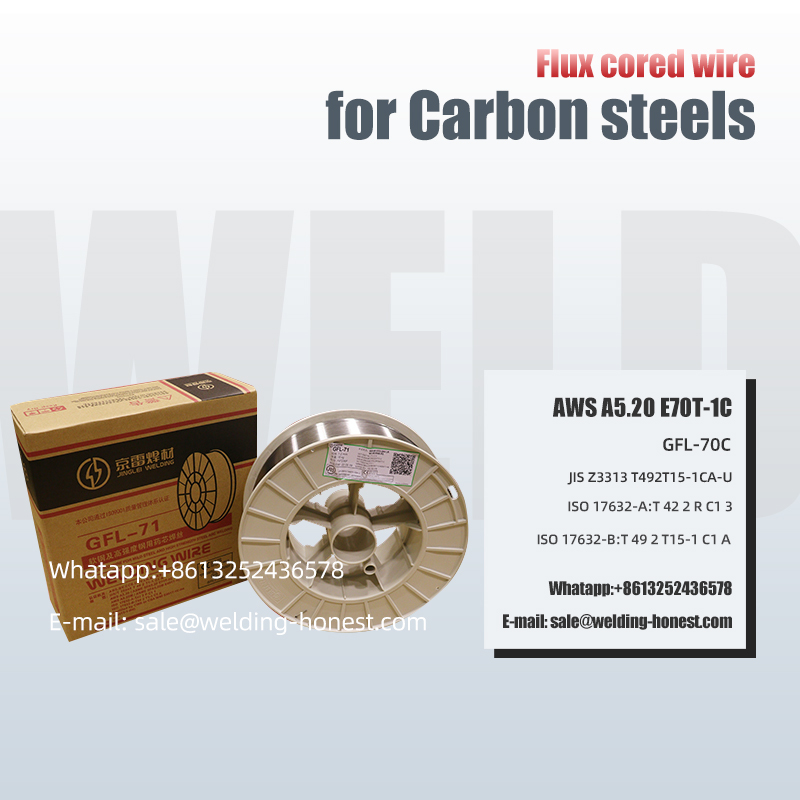

High Carbon steels Manual electrode E7015-G welding makings

Application

SSuitable FOR WELDING OF CARBON STEEL AND LOW ALLOY STEEL, AS WELL AS THE corresponding strength of boiler, pipeline, pressure vessel, ocean engineering structure welding, such as Q345, X60 pipeline steel, etc.

The standard we met: GB/T5117 E5015-G AP, AWS A5.5 E7015-G & A5.5M E4915-G, ISO2560-A:E 42 4 Z0.5 Ni B 2 2, ISO 2560-B: E4915 G-AP.

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T RULES | - | - | - | - | - | - | - | - | - |

| AWS RULES | - | ≥1.00 | ≥0.80 | ≥0.30 | ≥0.50 | ≥0.20 | 0.030 | 0.030 | ≥0.10 |

| EXAMPLE VALUE | 0.075 | 1.45 | 0.40 | 0.03 | 0.50 | 0.004 | 0.014 | 0.006 | 0.01 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 400 | 490 | 620*1 | - | 20 | ||||

| AWS RULES | 390 | 490 | 620*1 | - | 22 | ||||

| EXAMPLE VALUE | 450 | 550 | 620*1 | 114/-50 | 27 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| ELECTRICITY (Amp) |

H/W | 80-110 | 110-130 | 130-180 | 180-230 | ||||

| O/W | 50-80 | 90-120 | 130-160 | - | |||||

Peculiarity

Low hydrogen potassium electrode, stable arc, beautiful forming, exquisite, little splash, easy de-slagging, good skin fire resistance, good porosity resistance.

Table mechanical properties, good plasticity, impact toughness and crack resistance.

Diffused hydrogen content is low.

Show details

Fine ripple

Splash very little

About us

Factory fioor display

Application case

Xinjiang Kela 2 Central treatment plant project

Welding material for silencer

Actual factory shooting

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T RULES | - | - | - | - | - | - | - | - | - |

| AWS RULES | - | ≥1.00 | ≥0.80 | ≥0.30 | ≥0.50 | ≥0.20 | 0.030 | 0.030 | ≥0.10 |

| EXAMPLE VALUE | 0.075 | 1.45 | 0.40 | 0.03 | 0.50 | 0.004 | 0.014 | 0.006 | 0.01 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 400 | 490 | 620*1 | - | 20 | ||||

| AWS RULES | 390 | 490 | 620*1 | - | 22 | ||||

| EXAMPLE VALUE | 450 | 550 | 620*1 | 114/-50 | 27 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| ELECTRICITY (Amp) |

H/W | 80-110 | 110-130 | 130-180 | 180-230 | ||||

| O/W | 50-80 | 90-120 | 130-160 | - | |||||