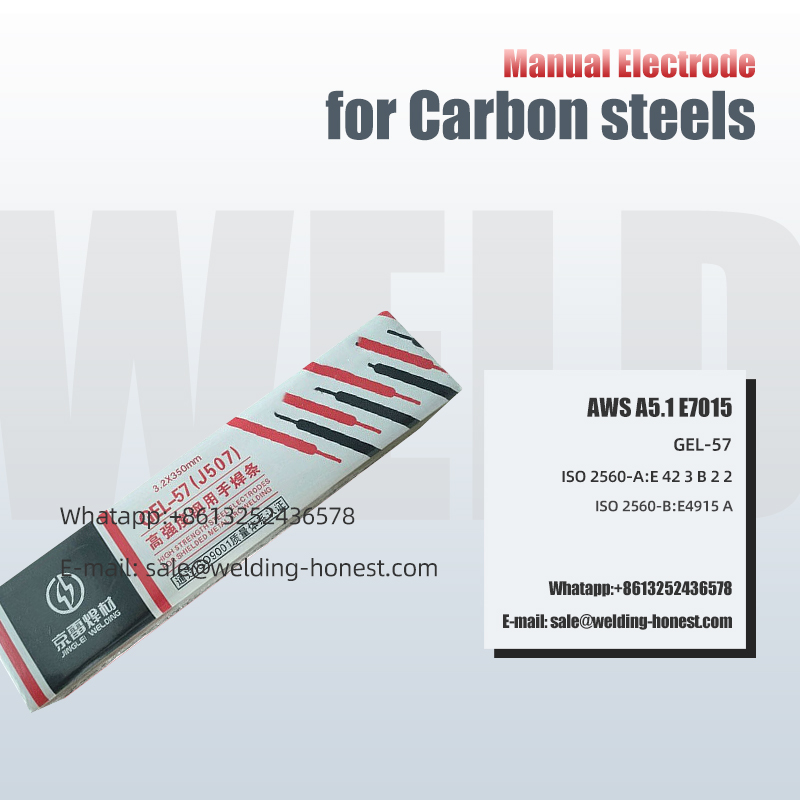

High Carbon steels Manual electrode E7015 metal Jointing connection

Suitable FOR WELDING OF CARBON STEEL AND LOW ALLOY STEEL, AS WELL AS THE CORRESPONDING STRENGTH OF BOILER, pipeline, vehicle, BUILDING, BRIDGE AND other STRUCTURES, SUCH AS Q345.

The standard we met: GB/T5117 E501, AWS A5.1 E701 & A5.1M E491, ISO2560-A:E 42 3 B 2 2, ISO 2560-B: E4915 A.

What are the

characieristics?

●Low hydrogen potassium electrode, stable arc, beautiful forming, exquisite.

● Little splash, easy de-slagging, good skin fire resistance, good porosity resistance.

●Table mechanical properties, good plasticity.

●Impact toughness and crack resistance.

Product Parameter

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T RULES | 0.15 | 1.60 | 0.90 | 0.20 | 0.30 | 0.30 | 0.035 | 0.035 | 0.08 |

| AWS RULES | 0.15 | 1.25 | 0.75 | 0.20 | 0.30 | 0.30 | 0.035 | 0.035 | 0.08 |

| EXAMPLE VALUE | 0.075 | 1317 | 0.5 | 0.04 | 0.02 | 0.007 | 0.017 | 0.009 | 0.01 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 400 | 490 | AW | 27/-30 | 20 | ||||

| AWS RULES | 400 | 490 | AW | 27/-30 | 22 | ||||

| EXAMPLE VALUE | 460 | 555 | AW | 120/-30 | 30 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| ELECTRICITY (Amp) |

H/W | 80-110 | 100-130 | 130-180 | 180-230 | ||||

| O/W | 50-80 | 90-120 | 130-160 | - | |||||

Look at the way

we transport

●Motor transport

●Shipping

Look at

our warenouse

The projects

we are involve in

●Welding materials for silencers

●8.2-ton bulk carrier

Our products

to the world

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T RULES | 0.15 | 1.60 | 0.90 | 0.20 | 0.30 | 0.30 | 0.035 | 0.035 | 0.08 |

| AWS RULES | 0.15 | 1.25 | 0.75 | 0.20 | 0.30 | 0.30 | 0.035 | 0.035 | 0.08 |

| EXAMPLE VALUE | 0.075 | 1317 | 0.5 | 0.04 | 0.02 | 0.007 | 0.017 | 0.009 | 0.01 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 400 | 490 | AW | 27/-30 | 20 | ||||

| AWS RULES | 400 | 490 | AW | 27/-30 | 22 | ||||

| EXAMPLE VALUE | 460 | 555 | AW | 120/-30 | 30 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| ELECTRICITY (Amp) |

H/W | 80-110 | 100-130 | 130-180 | 180-230 | ||||

| O/W | 50-80 | 90-120 | 130-160 | - | |||||

Write your message here and send it to us