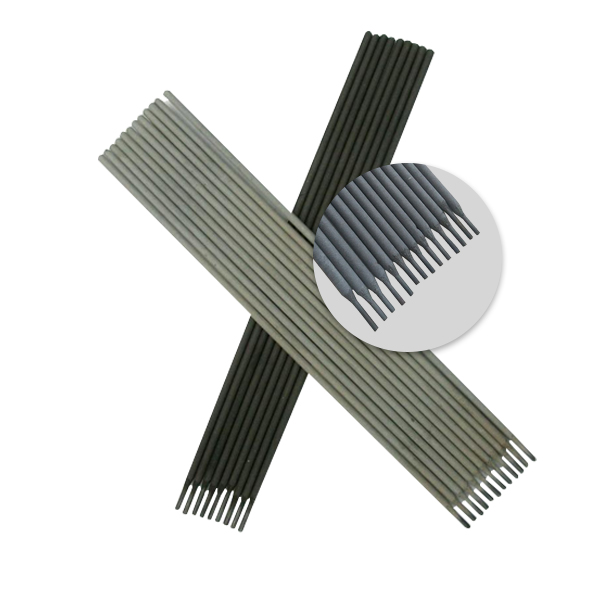

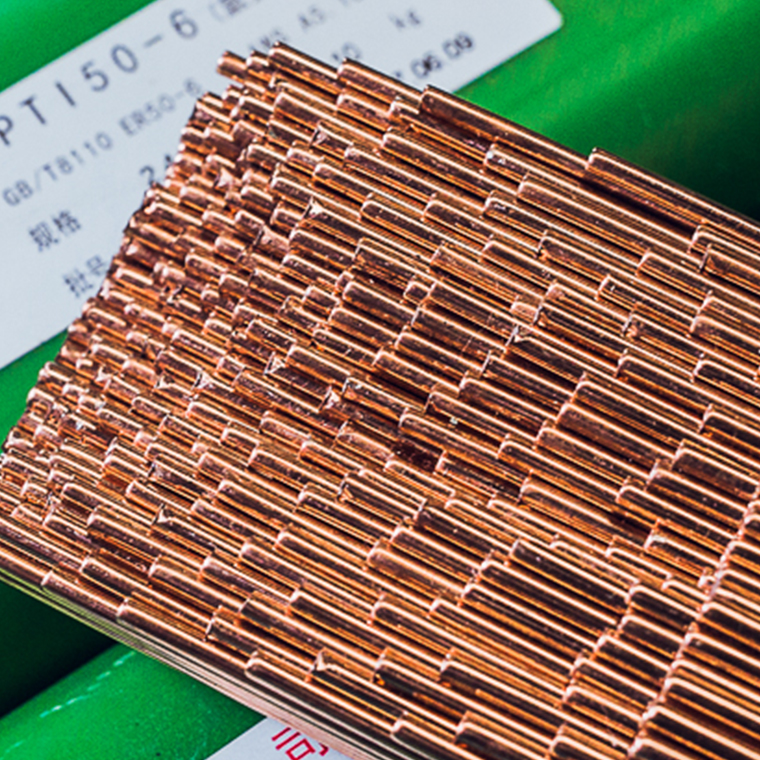

High Carbon steels Manual electrode E8815-G Soldering connection

Application

Suitable for the same grade of low alloy steel welding in construction machinery.

The standard we met: GB/T32533 E8815-G, AWS, ISO18275-A, ISO 18275-B.

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu | V |

| GB/T RULES | - | ≥1.00 | ≥0.80 | ≥0.30 | ≥0.50 | ≥0.20 | - | - | ≥0.20 | ≥0.10 |

| AWS RULES | - | - | - | - | - | - | - | - | - | - |

| EXAMPLE VALUE | 0.056 | 1.56 | 0.25 | 0.92 | 2.52 | 0.28 | 0.010 | 0.005 | 0.020 | 0.01 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | |||||

| GB/T RULES | 780 | 880 | AW | - | 12 | |||||

| AWS RULES | - | - | - | - | - | |||||

| EXAMPLE VALUE | 843 | 949 | AW | 51/-50 | 20 | |||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | ||||||

| ELECTRICITY (Amp) |

H/W | 80-110 | 100-130 | 130-180 | 180-230 | |||||

| O/W | 50-80 | 90-120 | 130-160 | - | ||||||

Peculiarity

Low sodium hydrogen electrode, stable arc, small splash.

Good forming, easy desagging.

X-ray performance is good, stable mechanical properties.

Show details

Arc stabilization

Beautiful shape

About us

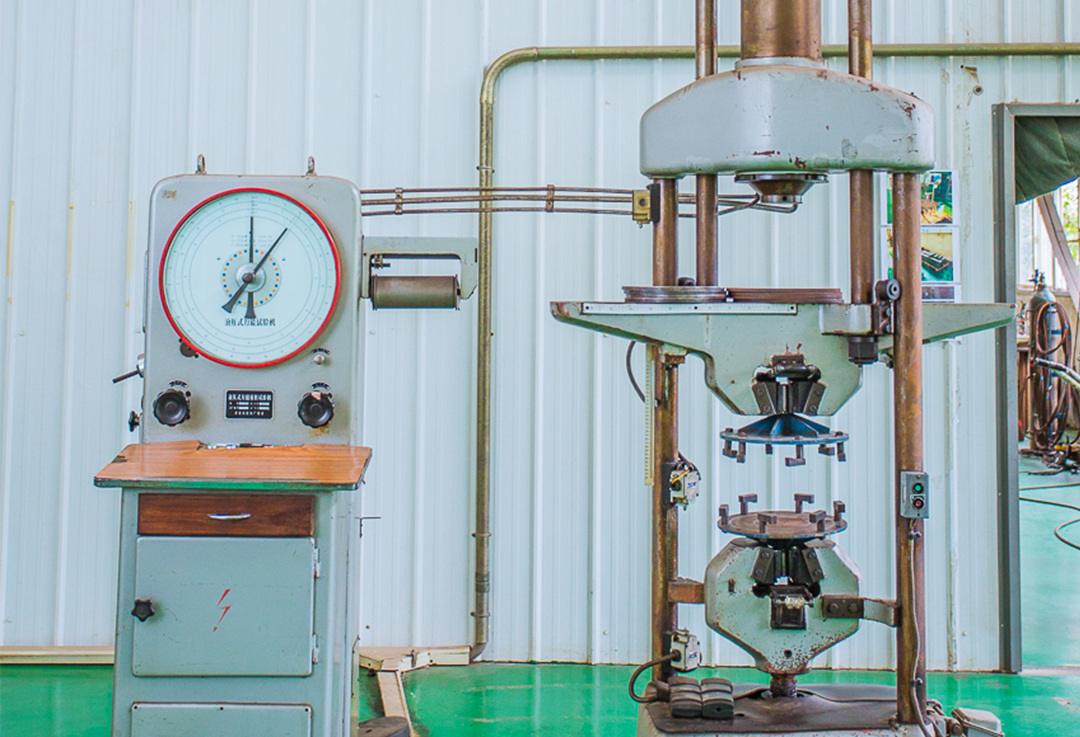

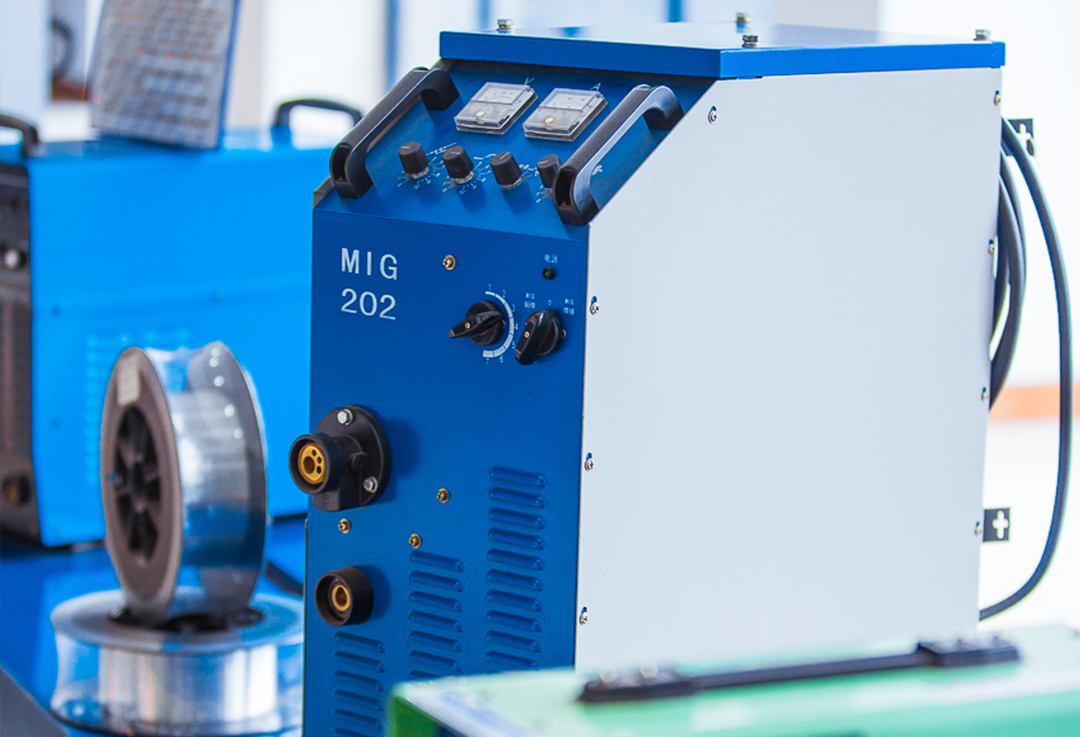

Factory fioor display

Application case

Welding materials for containers

Petrochemical equipment

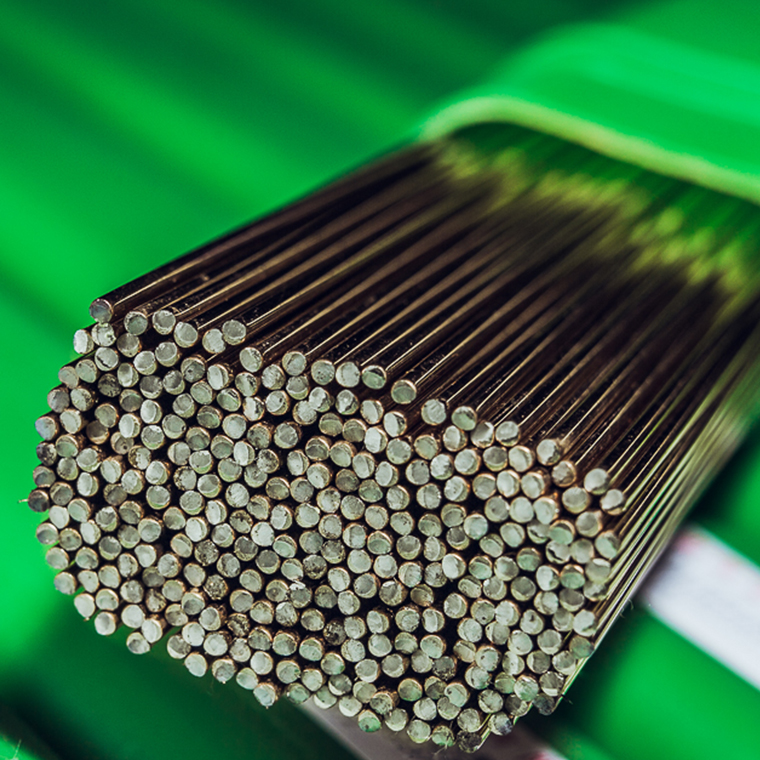

Actual factory shooting

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu | V |

| GB/T RULES | - | ≥1.00 | ≥0.80 | ≥0.30 | ≥0.50 | ≥0.20 | - | - | ≥0.20 | ≥0.10 |

| AWS RULES | - | - | - | - | - | - | - | - | - | - |

| EXAMPLE VALUE | 0.056 | 1.56 | 0.25 | 0.92 | 2.52 | 0.28 | 0.010 | 0.005 | 0.020 | 0.01 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | |||||

| GB/T RULES | 780 | 880 | AW | - | 12 | |||||

| AWS RULES | - | - | - | - | - | |||||

| EXAMPLE VALUE | 843 | 949 | AW | 51/-50 | 20 | |||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | ||||||

| ELECTRICITY (Amp) |

H/W | 80-110 | 100-130 | 130-180 | 180-230 | |||||

| O/W | 50-80 | 90-120 | 130-160 | - | ||||||

Write your message here and send it to us