High Carbon steels Manual electrode E9016-G weld fabrication jointing

Application

Suitable for welding of low alloy steel and medium carbon steel of the same strength grade.

The standard we met: GB/T32533 E5916-G P, AWS A5.5 E9016-G & A5.5M E6216-G, ISO256018275-A, ISO 18275-B: E6216-G P.

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T RULES | - | ≥1.00 | ≥0.80 | ≥0.30 | ≥0.50 | ≥0.20 | - | - | ≥0.10 |

| AWS RULES | - | ≥1.00 | ≥0.80 | ≥0.30 | ≥0.50 | ≥0.20 | 0.035 | 0.030 | ≥0.10 |

| EXAMPLE VALUE | 0.07 | 1.55 | 0.38 | 0.03 | 0.70 | 0.31 | 0.012 | 0.006 | 0.001 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 490 | 590 | 620*1 | 27/-20 | 16 | ||||

| AWS RULES | 530 | 620 | 620*1 | - | 17 | ||||

| EXAMPLE VALUE | 570 | 660 | 620*1 | 150/-30 | 27 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| ELECTRICITY (Amp) |

H/W | 80-110 | 110-130 | 130-180 | 180-230 | ||||

| O/W | 50-80 | 90-120 | 130-160 | - | |||||

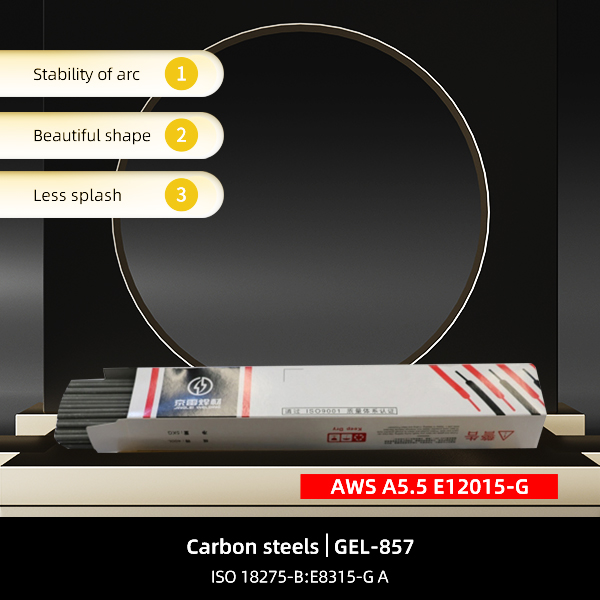

Peculiarity

Low hydrogen potassium electrode.

Stable arc, small splash, beautiful shape.

Stable mechanical properties.

Show details

Stability of arc

Splash small

About us

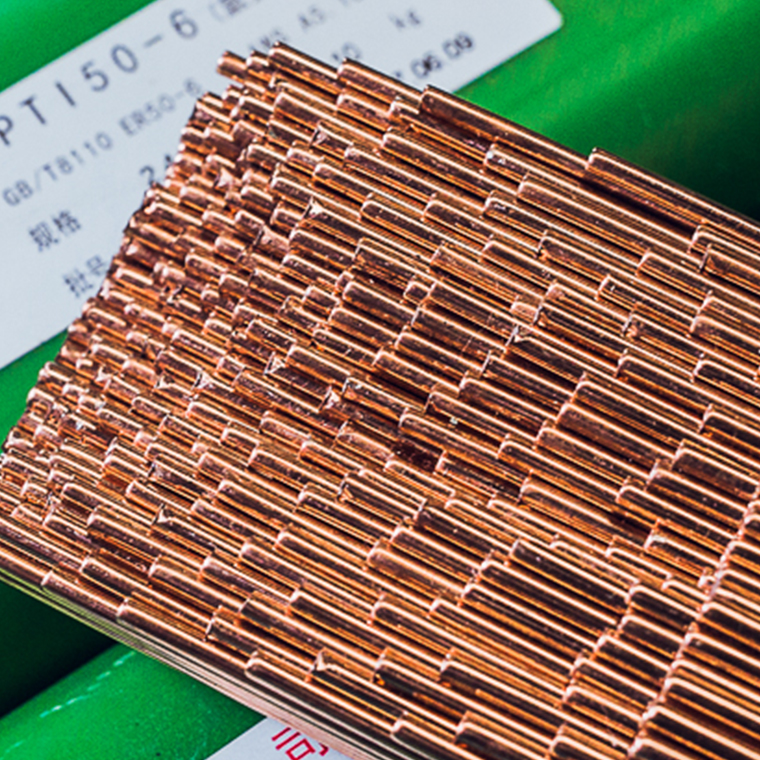

Factory fioor display

Application case

Gansu Lanke Petrochemical -50℃ propane spherical tank project

High pressure heater of Hangzhou Boiler Group Co. LTD

Actual factory shooting

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T RULES | - | ≥1.00 | ≥0.80 | ≥0.30 | ≥0.50 | ≥0.20 | - | - | ≥0.10 |

| AWS RULES | - | ≥1.00 | ≥0.80 | ≥0.30 | ≥0.50 | ≥0.20 | 0.035 | 0.030 | ≥0.10 |

| EXAMPLE VALUE | 0.07 | 1.55 | 0.38 | 0.03 | 0.70 | 0.31 | 0.012 | 0.006 | 0.001 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 490 | 590 | 620*1 | 27/-20 | 16 | ||||

| AWS RULES | 530 | 620 | 620*1 | - | 17 | ||||

| EXAMPLE VALUE | 570 | 660 | 620*1 | 150/-30 | 27 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| ELECTRICITY (Amp) |

H/W | 80-110 | 110-130 | 130-180 | 180-230 | ||||

| O/W | 50-80 | 90-120 | 130-160 | - | |||||

Write your message here and send it to us