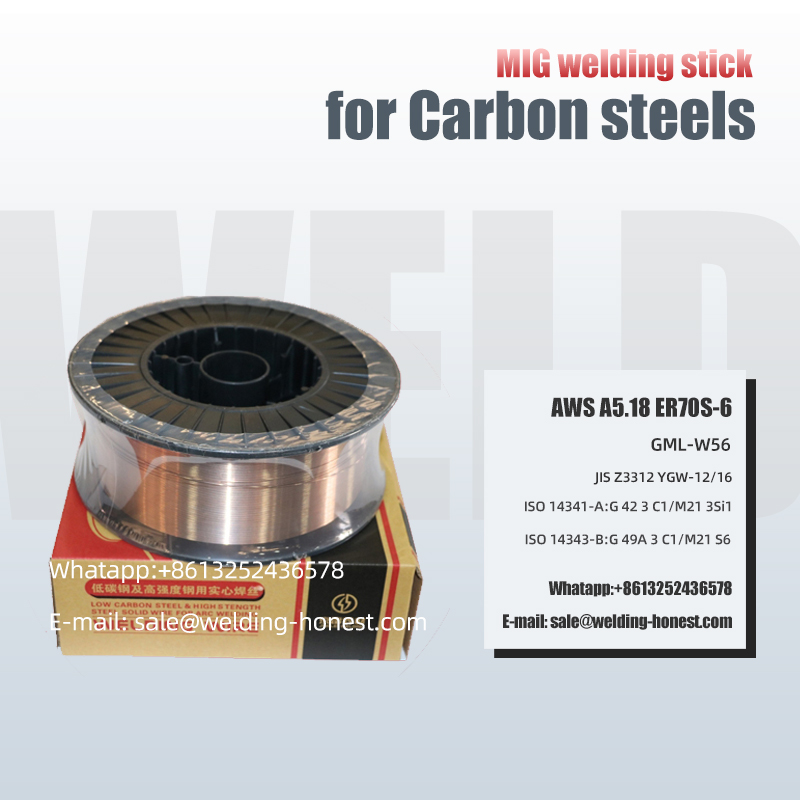

High Carbon steels MIG ER70S-6 Seal makings

Suitable for automobile, bridge, construction, shipbuilding, machinery, pressure vessel, boiler and other welding occasions, can also be used for plate, pipe welding.

The standard we met: GB/T8110 G 49A 3 C1/M21 S6 N , AWS A5.18 ER70S-6 & A5.18M ER49S-6, ISO14341-A:G 42 3 C1/M21 3Si1, ISO14341-B:G 49A 3 C1/M21 S6, JIS Z3312 YGW-12/16.

What are the

characieristics?

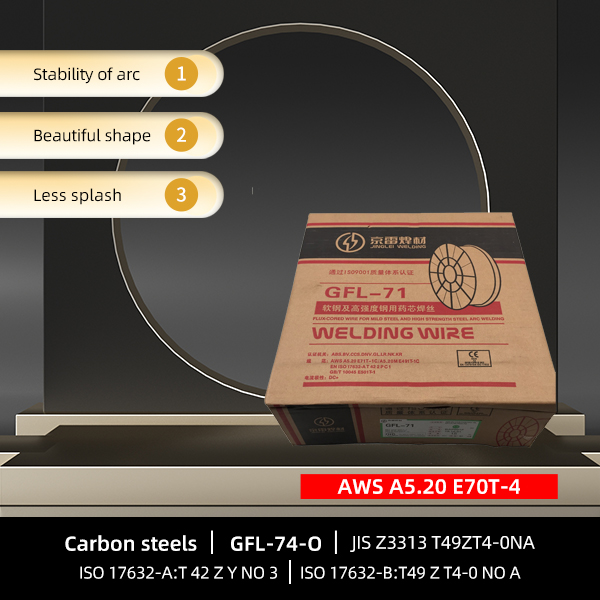

●Can be applied to a large welding current range, and in the low current welding arc stability.

●Less spark splash, weld forming beautiful.

●Weld metal porosity sensitivity is low.

●Has excellent mechanical properties.

Product Parameter

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu |

| GB/T RULES | 0.06-0.15 | 1.40-1.85 | 0.80-1.15 | 0.15 | 0.15 | 0.15 | 0.025 | 0.025 | 0.50 |

| AWS RULES | 0.06-0.15 | 1.40-1.85 | 0.80-1.15 | 0.15 | 0.15 | 0.15 | 0.025 | 0.035 | 0.50 |

| EXAMPLE VALUE | 0.075 | 1.450 | 0.83 | 0.02 | 0.02 | 0.001 | 0.015 | 0.010 | 0.020 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 390 | 490-670 | AW | 27/-30 | 18 | ||||

| AWS RULES | 400 | 490 | AW | 27/-30 | 22 | ||||

| EXAMPLE VALUE | 455 | 560 | AW | 73/-30 | 28 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 1 | 1.2 | 1.6 | ||||

| ELECTRICITY (Amp) |

H/W | 80-250 | 100-350 | 250-300 | |||

| O/W | 70-120 | 80-150 | |||||

Look at the way

we transport

●Motor transport

●Shipping

Look at

our warenouse

The projects

we are involve in

●China Global demethane Tower

●GDS-2209/GXS-E330 tube surfacing site

Our products

to the world

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu |

| GB/T RULES | 0.06-0.15 | 1.40-1.85 | 0.80-1.15 | 0.15 | 0.15 | 0.15 | 0.025 | 0.025 | 0.50 |

| AWS RULES | 0.06-0.15 | 1.40-1.85 | 0.80-1.15 | 0.15 | 0.15 | 0.15 | 0.025 | 0.035 | 0.50 |

| EXAMPLE VALUE | 0.075 | 1.450 | 0.83 | 0.02 | 0.02 | 0.001 | 0.015 | 0.010 | 0.020 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 390 | 490-670 | AW | 27/-30 | 18 | ||||

| AWS RULES | 400 | 490 | AW | 27/-30 | 22 | ||||

| EXAMPLE VALUE | 455 | 560 | AW | 73/-30 | 28 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 1 | 1.2 | 1.6 | ||||

| ELECTRICITY (Amp) |

H/W | 80-250 | 100-350 | 250-300 | |||

| O/W | 70-120 | 80-150 | |||||

Write your message here and send it to us