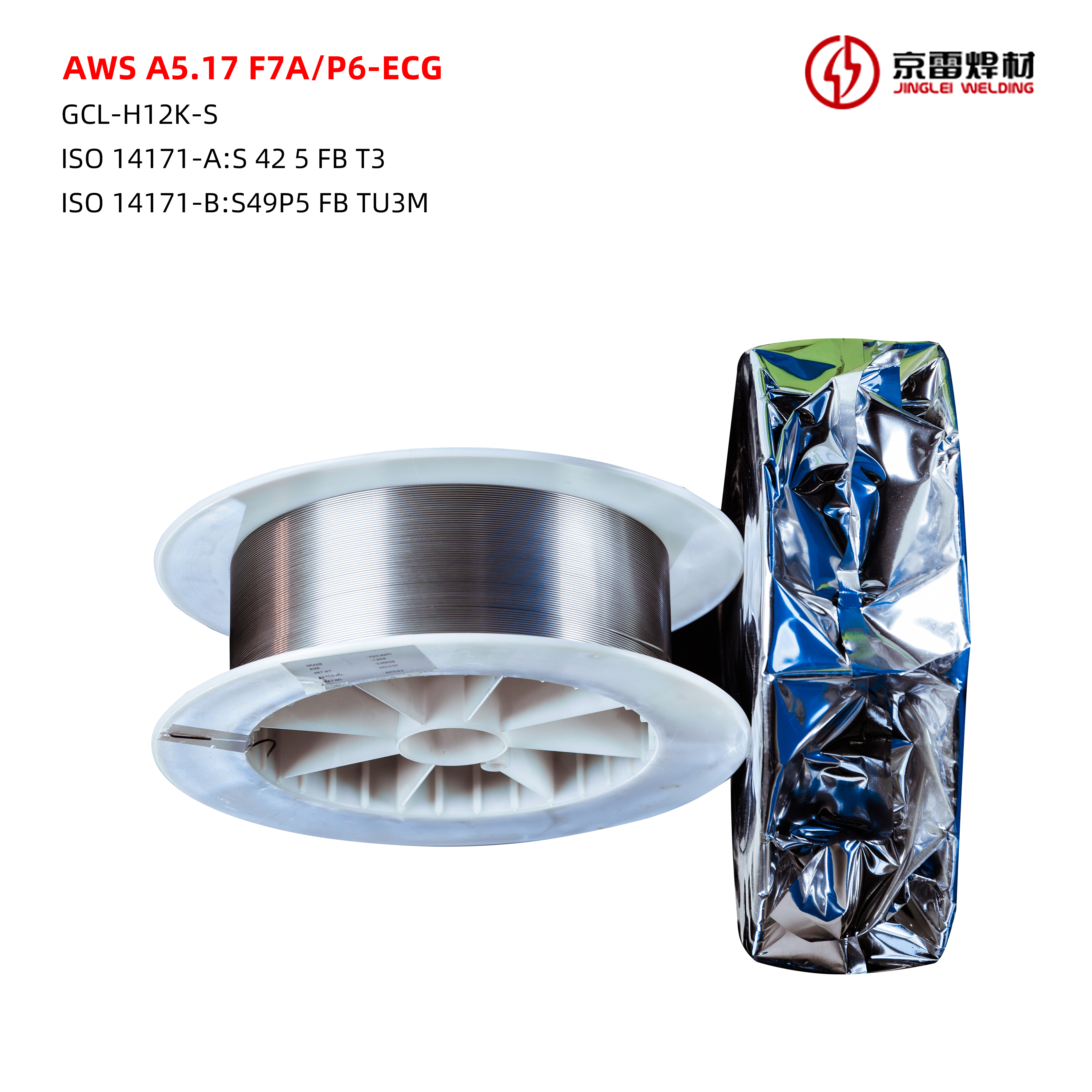

High Carbon steels SAW welding wire F7A/P6-ECG and welding flux weld fabrication stuff

Used for -50C impact required environment, generally used for shipbuilding, pipeline, pressure vessel welding.

What are the characieristics?

●Metal powder core submerged arc welding wire for 480MPa grade high strength steel; With GXL-121 flux welding, welding arc combustion is stable, easy to remove slag, welding pass forming beautiful.

●The weld metal has excellent mechanical properties, low content of P and S, and excellent low temperature impact performance.

Product Parameter

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Si | Mn | P | S | Ni | Cr | Mo |

| GB/T RULES | 0.056 | 0.295 | 1.65 | 0.015 | 0.005 | 0.015 | 0.024 | 0.25 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | ELONGATION % | IMAPACT VALUE J/℃ | Heat treatment °C*h | ||||

| GB/T RULES | 463 | 550 | 31 | 110/-50 | 590*5 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 3.2 | 4.0 | |||

| Voltage(Volt) | 28-32 | 28-32 | |||

| Electricity(Amp) | 400-550 | 500-650 | |||

| Speed(mm/min) | 300-420 | 400-480 | |||

| Dry stretch length(mm) | 22-26 | 30-34 |

Mode of transportation

●Motor transport

●Shipping

Our warehouse

We participate in the program

●Guangxi Huayi esterification tower

●Thermal power application

Our products to the world

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Si | Mn | P | S | Ni | Cr | Mo |

| GB/T RULES | 0.056 | 0.295 | 1.65 | 0.015 | 0.005 | 0.015 | 0.024 | 0.25 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | ELONGATION % | IMAPACT VALUE J/℃ | Heat treatment °C*h | ||||

| GB/T RULES | 463 | 550 | 31 | 110/-50 | 590*5 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 3.2 | 4.0 | |||

| Voltage(Volt) | 28-32 | 28-32 | |||

| Electricity(Amp) | 400-550 | 500-650 | |||

| Speed(mm/min) | 300-420 | 400-480 | |||

| Dry stretch length(mm) | 22-26 | 30-34 |

Write your message here and send it to us