Low-alloy steels Flux cored wire E71T-1C-J Seal stuff

Application

Suitable for ship, bridge, construction, offshore platform, pipeline, steel structure welding.

The standard we met: GB/T10045 T 49 4 T1-1 C1 P , AWS A5.20 E71T-1C-J & A5.20M E491T-1C-J, ISO17632-A:T42 4 P C1 1, ISO 17632-B:T49 4 T1-1 C1 P.

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T RULES | 0.18 | 2.00 | 0.90 | 0.20 | 0.50 | 0.30 | 0.030 | 0.030 | 0.08 |

| AWS RULES | 0.12 | 1.75 | 0.90 | 0.20 | 0.50 | 0.30 | 0.03 | 0.03 | 0.08 |

| EXAMPLE VALUE | 0.040 | 1.200 | 0.30 | 0.02 | 0.45 | 0.01 | 0.010 | 0.005 | 0.01 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 390 | 490-670 | AW | 27/-40 | 18 | ||||

| AWS RULES | 390 | 490-670 | AW | 27/-40 | 22 | ||||

| EXAMPLE VALUE | 495 | 560 | AW | 121/-40 | 31 | ||||

| EXAMPLE VALUE | 470 | 545 | 620*5 | 100/-40 | 30 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 1.2 | 1.4 | 1.6 | ||||

| VOLT | 23-32 | 24-36 | 25-40 | ||||

| AMP | 150-300 | 170-360 | 200-400 | ||||

| LENGTH:MM | 15-20 | 15-20 | 18-25 | ||||

| L/MIN | 15-25 | 15-25 | 15-25 |

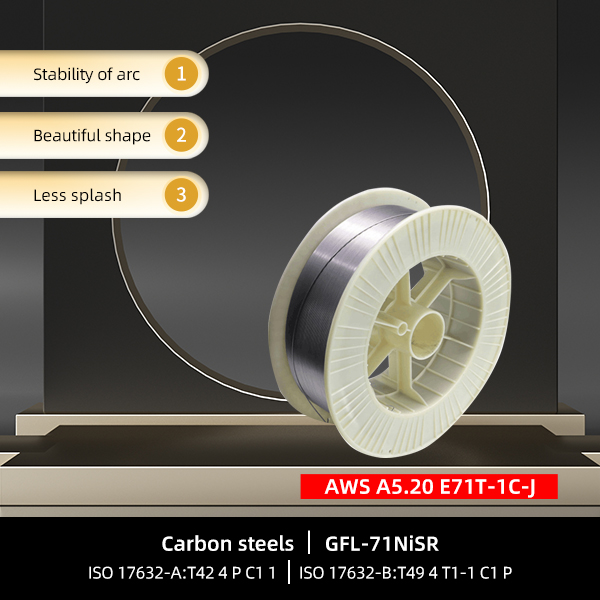

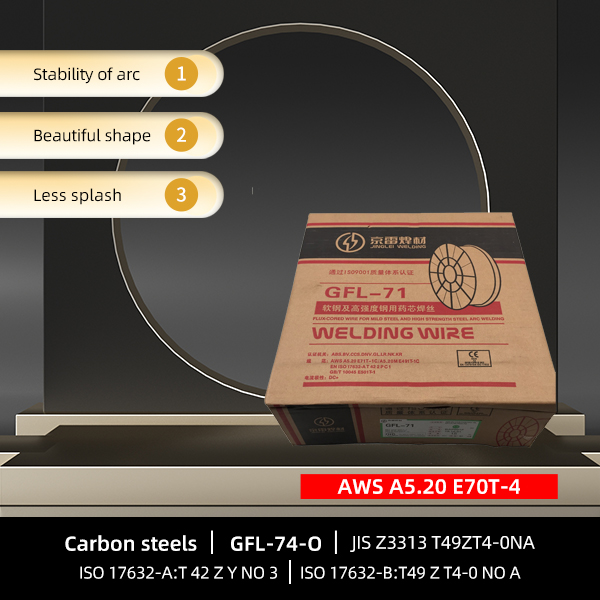

Peculiarity

Post-welding heat treatment is available.

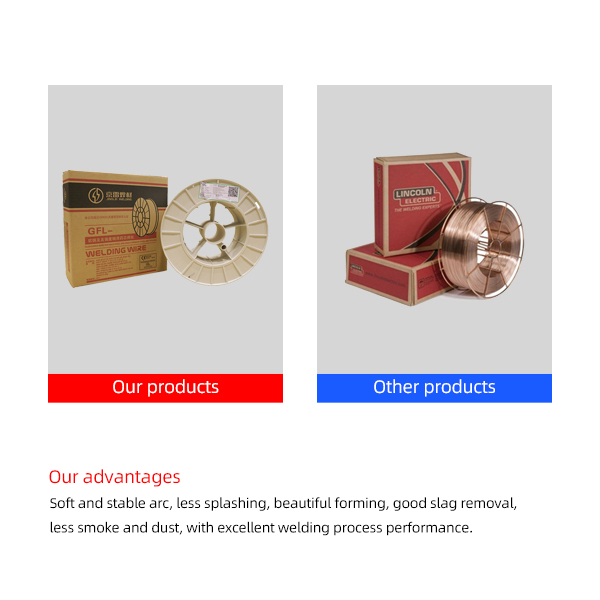

The arc is soft and stable, less splash, beautiful forming, good slag removal, less soot, with excellent welding process performance.

Excellent performance in welding state and heat treatment state.

-40℃ low temperature impact performance is excellent, CTOD performance is stable.

Show details

Soft and stable

Less splash

About us

Factory fioor display

Application case

Sino-russian Eastern Front

Polypropylene reactor

Actual factory shooting

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T RULES | 0.18 | 2.00 | 0.90 | 0.20 | 0.50 | 0.30 | 0.030 | 0.030 | 0.08 |

| AWS RULES | 0.12 | 1.75 | 0.90 | 0.20 | 0.50 | 0.30 | 0.03 | 0.03 | 0.08 |

| EXAMPLE VALUE | 0.040 | 1.200 | 0.30 | 0.02 | 0.45 | 0.01 | 0.010 | 0.005 | 0.01 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 390 | 490-670 | AW | 27/-40 | 18 | ||||

| AWS RULES | 390 | 490-670 | AW | 27/-40 | 22 | ||||

| EXAMPLE VALUE | 495 | 560 | AW | 121/-40 | 31 | ||||

| EXAMPLE VALUE | 470 | 545 | 620*5 | 100/-40 | 30 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 1.2 | 1.4 | 1.6 | ||||

| VOLT | 23-32 | 24-36 | 25-40 | ||||

| AMP | 150-300 | 170-360 | 200-400 | ||||

| LENGTH:MM | 15-20 | 15-20 | 18-25 | ||||

| L/MIN | 15-25 | 15-25 | 15-25 |

Write your message here and send it to us