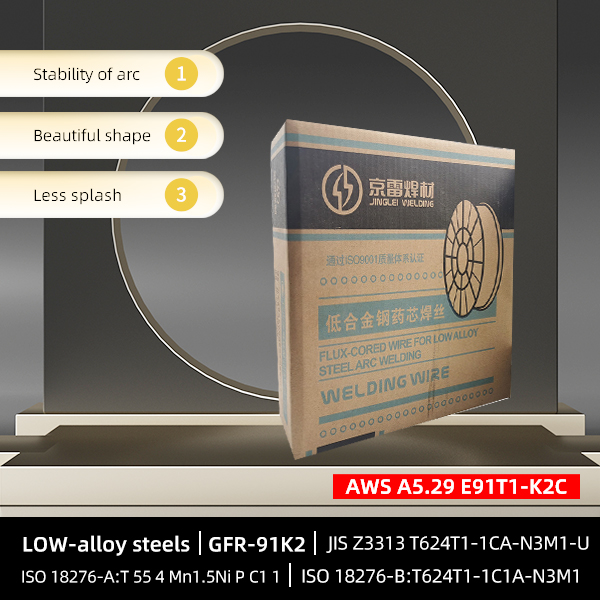

Low-alloy steels Flux cored wire E81T1-B6C Welding jointing

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu |

| GB/T RULES | 0.05-0.12 | 1.25 | 1.00 | 4.0-6.0 | 0.40 | 0.45-0.65 | 0.03 | 0.03 | 0.50 |

| AWS RULES | 0.05-0.12 | 1.25 | 1.00 | 4.0-6.0 | 0.40 | 0.45-0.65 | 0.03 | 0.03 | 0.50 |

| EXAMPLE VALUE | 0.055 | 0.7 | 0.3 | 5 | 0.02 | 0.55 | 0.005 | 0.005 | 0.01 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | Heat treatment°Cxh | |||||

| GB/T RULES | 470 | 550-690 | - | 17 | 745*2 | |||||

| AWS RULES | 470 | 550-690 | - | 19 | 745*2 | |||||

| EXAMPLE VALUE | 585 | 655 | 60/Normal temperature | 22 | 745*2 | |||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 1.2 | ||||

| Volt | 24-35 | ||||

| Amp | 160-320 | ||||

| Dry extension length(mm) | 15-20 | ||||

| Gas flow(l/min) | 15-25 | ||||

The arc is soft and stable, less splash, beautiful forming.

Good slag removal, less soot.

With excellent welding process performance.

Zhangjiagang CIMC Sundayin Cryogenic Equipment Co., LTD. Cryogenic Container (LNG Filling station)

Tangshan LNG export pipeline project

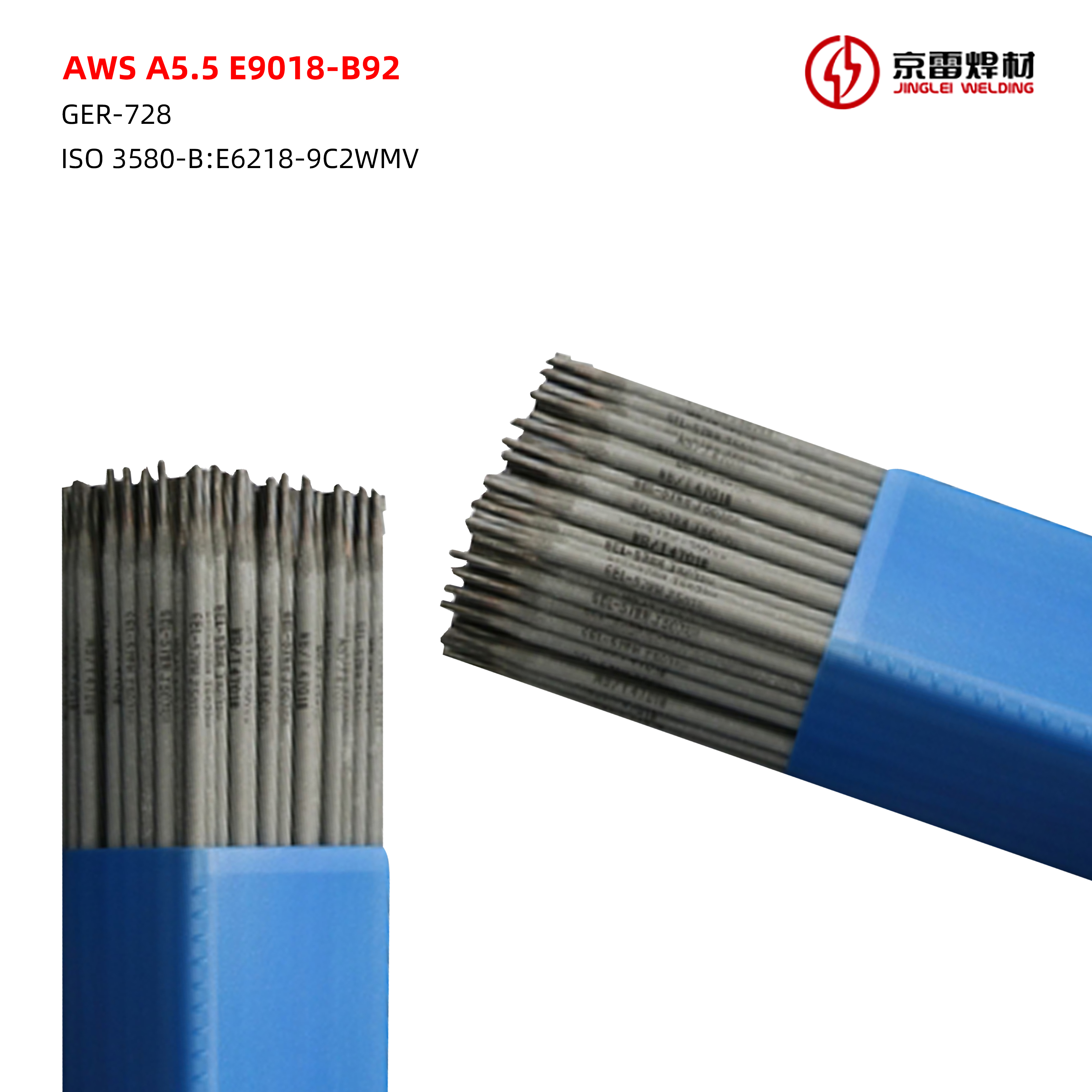

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu |

| GB/T RULES | 0.05-0.12 | 1.25 | 1.00 | 4.0-6.0 | 0.40 | 0.45-0.65 | 0.03 | 0.03 | 0.50 |

| AWS RULES | 0.05-0.12 | 1.25 | 1.00 | 4.0-6.0 | 0.40 | 0.45-0.65 | 0.03 | 0.03 | 0.50 |

| EXAMPLE VALUE | 0.055 | 0.7 | 0.3 | 5 | 0.02 | 0.55 | 0.005 | 0.005 | 0.01 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | Heat treatment°Cxh | |||||

| GB/T RULES | 470 | 550-690 | - | 17 | 745*2 | |||||

| AWS RULES | 470 | 550-690 | - | 19 | 745*2 | |||||

| EXAMPLE VALUE | 585 | 655 | 60/Normal temperature | 22 | 745*2 | |||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 1.2 | ||||

| Volt | 24-35 | ||||

| Amp | 160-320 | ||||

| Dry extension length(mm) | 15-20 | ||||

| Gas flow(l/min) | 15-25 | ||||

Write your message here and send it to us