Low-alloy steels Flux cored wire E91T1-B3C Welding data

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S |

| GB/T RULES | 0.05-0.12 | 1.25 | 0.80 | 2.0-2.5 | - | 0.90-1.20 | 0.03 | 0.03 |

| AWS RULES | 0.05-0.12 | 1.25 | 0.80 | 2.0-2.5 | - | 0.90-1.20 | 0.03 | 0.03 |

| EXAMPLE VALUE | 0.055 | 0.63 | 0.32 | 2.2 | 0.02 | 1 | 0.01 | 0.005 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | Heat treatment°Cxh | |||||

| GB/T RULES | 540 | 620-760 | - | 15 | 690*1 | |||||

| AWS RULES | 540 | 620-760 | - | 17 | 690*1 | |||||

| EXAMPLE VALUE | 650 | 730 | 90/Normal temperature | 20 | 690*1 | |||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 1.2 | ||||

| Volt | 24-35 | ||||

| Amp | 160-320 | ||||

| Dry extension length(mm) | 15-20 | ||||

| Gas flow(l/min) | 15-25 | ||||

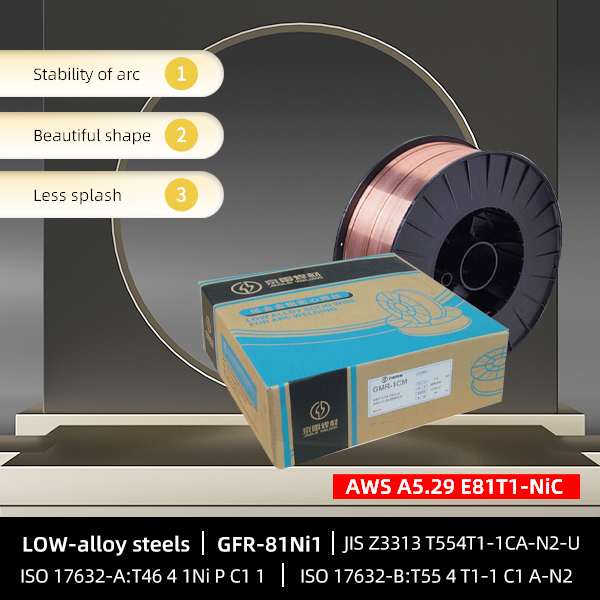

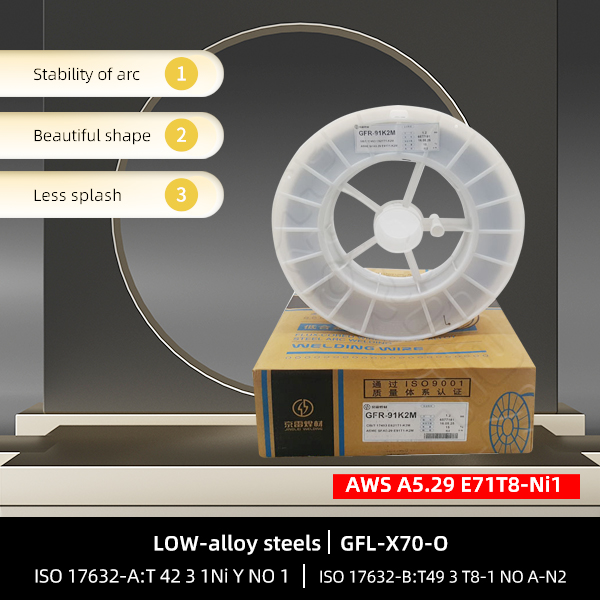

The arc is soft and stable, less splash, beautiful forming.

Good slag removal, less soot.

With excellent welding process performance.

-

Jiangsu Donghua Energy 80,000 m3 propane storage tank

-

Arctic LNG-2 project

-

Welding material for silencer

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S |

| GB/T RULES | 0.05-0.12 | 1.25 | 0.80 | 2.0-2.5 | - | 0.90-1.20 | 0.03 | 0.03 |

| AWS RULES | 0.05-0.12 | 1.25 | 0.80 | 2.0-2.5 | - | 0.90-1.20 | 0.03 | 0.03 |

| EXAMPLE VALUE | 0.055 | 0.63 | 0.32 | 2.2 | 0.02 | 1 | 0.01 | 0.005 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | Heat treatment°Cxh | |||||

| GB/T RULES | 540 | 620-760 | - | 15 | 690*1 | |||||

| AWS RULES | 540 | 620-760 | - | 17 | 690*1 | |||||

| EXAMPLE VALUE | 650 | 730 | 90/Normal temperature | 20 | 690*1 | |||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 1.2 | ||||

| Volt | 24-35 | ||||

| Amp | 160-320 | ||||

| Dry extension length(mm) | 15-20 | ||||

| Gas flow(l/min) | 15-25 | ||||

Write your message here and send it to us