Low-alloy steels Gas-shielded ER90S-G metal Jointing stuff

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu |

| GB/T RULES | 0.12 | 0.75-1.50 | 0.30-0.90 | 2.10-2.70 | - | 0.90-1.20 | 0.03 | 0.03 | 0.40 |

| AWS RULES | - | - | - | - | - | - | - | - | - |

| EXAMPLE VALUE | 0.075 | 0.85 | 0.60 | 2.5 | 0.03 | 1.00 | 0.01 | 0.005 | 0.05 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | Heat treatment°Cxh | |||||

| GB/T RULES | 540 | 620 | - | 15 | 690*1 | |||||

| AWS RULES | 540 | 620 | - | 17 | 690*1 | |||||

| EXAMPLE VALUE | 560 | 640 | 160/0Room temperature | 24 | 690*1 | |||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 1.0 | 1.2 | 1.6 | |||||||

| ELECTRICITY (Amp) |

H/W | 50-220 | 80-350 | 170-550 | ||||||

| O/W | 50-120 | 80-150 | - | |||||||

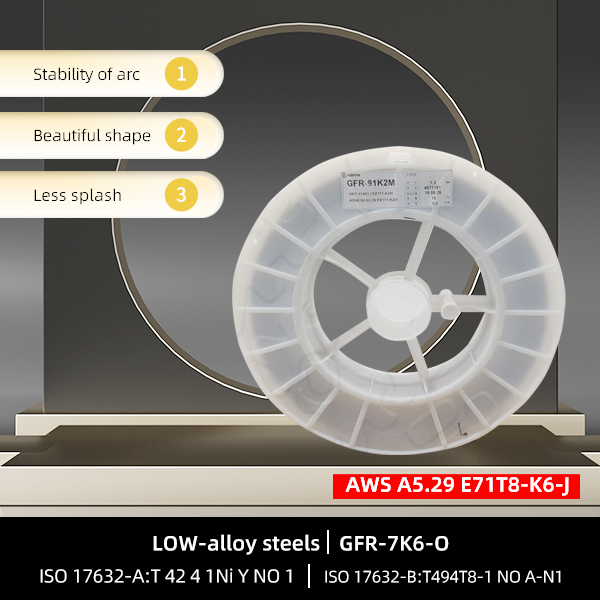

Gas shielded welding wire for heat resisting steel class 620MPa.

The wire is smooth, the arc is stable, the molding is beautiful, the molten iron is good, the welding technology is excellent.

The molten metal has good mechanical properties, has good porosity resistance and the weld forming.

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu |

| GB/T RULES | 0.12 | 0.75-1.50 | 0.30-0.90 | 2.10-2.70 | - | 0.90-1.20 | 0.03 | 0.03 | 0.40 |

| AWS RULES | - | - | - | - | - | - | - | - | - |

| EXAMPLE VALUE | 0.075 | 0.85 | 0.60 | 2.5 | 0.03 | 1.00 | 0.01 | 0.005 | 0.05 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | Heat treatment°Cxh | |||||

| GB/T RULES | 540 | 620 | - | 15 | 690*1 | |||||

| AWS RULES | 540 | 620 | - | 17 | 690*1 | |||||

| EXAMPLE VALUE | 560 | 640 | 160/0Room temperature | 24 | 690*1 | |||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 1.0 | 1.2 | 1.6 | |||||||

| ELECTRICITY (Amp) |

H/W | 50-220 | 80-350 | 170-550 | ||||||

| O/W | 50-120 | 80-150 | - | |||||||

Write your message here and send it to us