Low-alloy steels Manual electrode E7018-W1 Soldering connect

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Ni | Cr | Mo | V | Cu | P | S |

| GB/T RULES | 0.12 | 0.40-0.70 | 0.40-0.70 | 0.20-0.40 | 0.15-0.30 | - | 0.08 | 0.30-0.60 | 0.03 | 0.03 |

| AWS RULES | 0.12 | 0.40-0.70 | 0.40-0.70 | 0.20-0.40 | 0.15-0.30 | - | 0.08 | 0.30-0.60 | 0.03 | 0.03 |

| EXAMPLE VALUE | 0.052 | 0.55 | 0.5 | 0.33 | 0.27 | 0.008 | 0.03 | 0.43 | 0.015 | 0.008 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | Heat treatment°Cxh | |||||

| GB/T RULES | 420 | 490 | 27/-20 | 20 | AW | |||||

| AWS RULES | 415 | 490 | 27/-20 | 22 | AW | |||||

| EXAMPLE VALUE | 470 | 560 | 150/-20 | 26 | AW | |||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | ||||

| ELECTRICITY (Amp) |

H/W | 80-110 | 100-130 | 130-180 | 170-210 | |||

| O/W | 60-100 | 80-120 | 120-160 | - | ||||

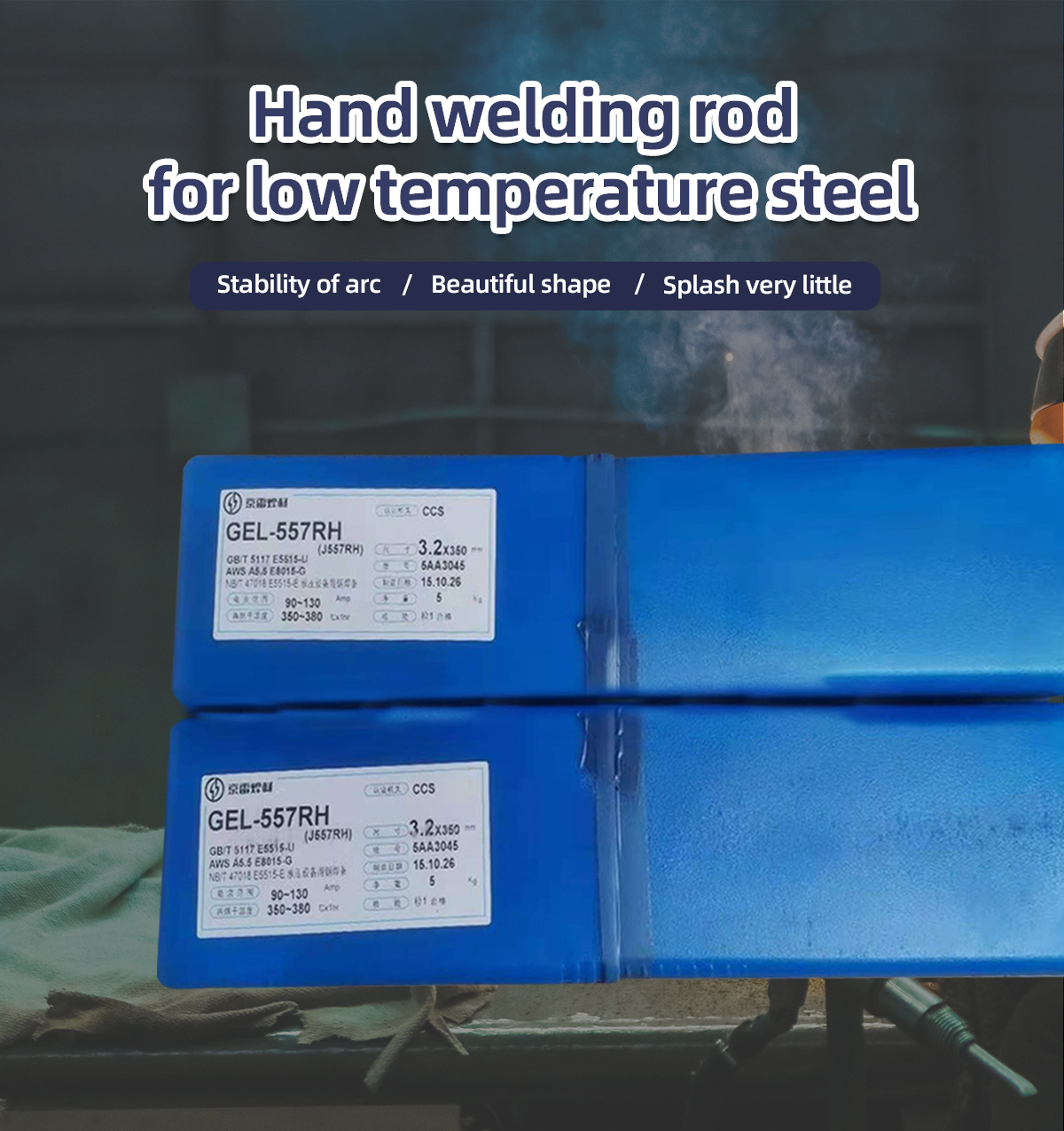

Iron powder low hydrogen type hand electrode, because its molten metal contains Cu, Ni, Cr.

So it has good atmospheric corrosion resistance, good cracking resistance.

Stable arc, less splash, good forming, easy slag removal, X-Ray performance is excellent.

-

Zhejiang Petrochemical 40 million tons/year refining and chemical integration project

-

Welding material for silencer

-

YAMAL LNG project

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Ni | Cr | Mo | V | Cu | P | S |

| GB/T RULES | 0.12 | 0.40-0.70 | 0.40-0.70 | 0.20-0.40 | 0.15-0.30 | - | 0.08 | 0.30-0.60 | 0.03 | 0.03 |

| AWS RULES | 0.12 | 0.40-0.70 | 0.40-0.70 | 0.20-0.40 | 0.15-0.30 | - | 0.08 | 0.30-0.60 | 0.03 | 0.03 |

| EXAMPLE VALUE | 0.052 | 0.55 | 0.5 | 0.33 | 0.27 | 0.008 | 0.03 | 0.43 | 0.015 | 0.008 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | Heat treatment°Cxh | |||||

| GB/T RULES | 420 | 490 | 27/-20 | 20 | AW | |||||

| AWS RULES | 415 | 490 | 27/-20 | 22 | AW | |||||

| EXAMPLE VALUE | 470 | 560 | 150/-20 | 26 | AW | |||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | ||||

| ELECTRICITY (Amp) |

H/W | 80-110 | 100-130 | 130-180 | 170-210 | |||

| O/W | 60-100 | 80-120 | 120-160 | - | ||||

Write your message here and send it to us