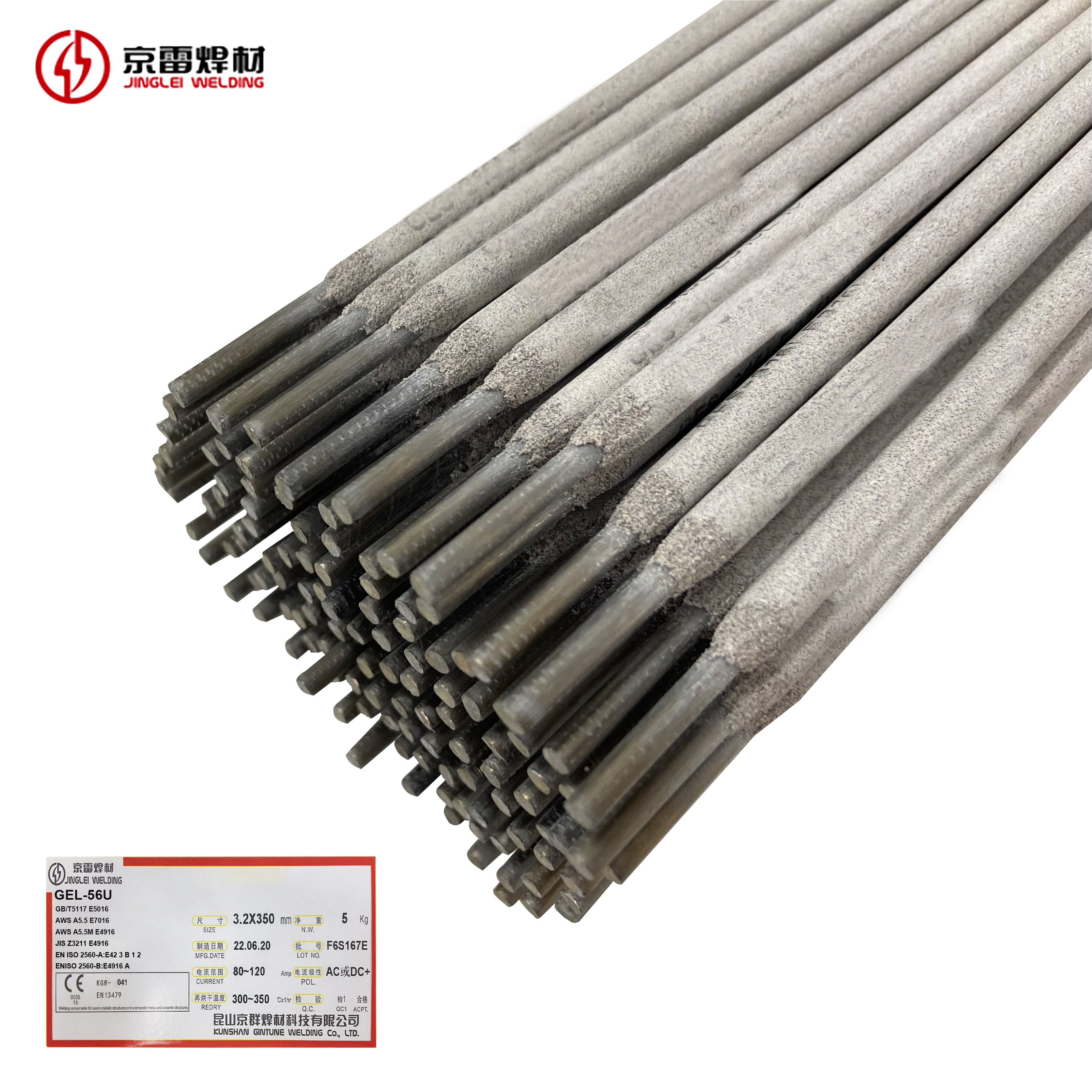

Low Carbon steels weld E7016 fabrication materials

It is suitable for double-sided forming during bottom welding. It is specially used for bottom welding to improve the working efficiency.

What are the characieristics?

●Low hydrogen potassium type hand electrode.

●Stable arc, small splash, easy slag removal, excellent fire resistance.

●Excellent cracking resistance, mechanical stability, plasticity, good impact toughness.

● It can be welded on one side and formed on both sides.

Product Parameter

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Si | Mn | P | S | Ni | Cr | Mo | Other |

| GB/T RULES | 0.06 | 0.50 | 0.95 | 0.009 | 0.01 | 0.01 | 0.012 | 0.005 | - |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | Heat treatment °C*h | ||||

| GB/T RULES | 445 | 540 | 34 | 100/-30 | - | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| ELECTRICITY (Amp) |

H/W | 55-85 | 90-130 | 130-180 | 180-240 | ||||

| O/W | 50-80 | 90-120 | 130-160 | - | |||||

Mode of transportation

●Motor transport

●Shipping

Our warehouse

We participate in the program

●300,000-ton Floating Production Storage Tanker (FPSO)

●Tangshan LNG export pipeline project

Our products to the world

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Si | Mn | P | S | Ni | Cr | Mo | Other |

| GB/T RULES | 0.06 | 0.50 | 0.95 | 0.009 | 0.01 | 0.01 | 0.012 | 0.005 | - |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | Heat treatment °C*h | ||||

| GB/T RULES | 445 | 540 | 34 | 100/-30 | - | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| ELECTRICITY (Amp) |

H/W | 55-85 | 90-130 | 130-180 | 180-240 | ||||

| O/W | 50-80 | 90-120 | 130-160 | - | |||||

Write your message here and send it to us