Low Carbon steels F6A0-EM12 SAW welding wire and welding flux welding accessories

Application & Standard

1. Suitable for welding of carbon steel and corresponding strength of boiler, pipeline, vehicle,

building, bridge and other structures, such as Q235.

2. The standard we met: GB/T5117 E4315, AWS, ISO2560-A:E 35 3 B 2 2, ISO 2560-B: E4315A

When welding carbon steel, the strength grade of the steel is typically chosen to match the electrode, taking into account the complex structure, thick plate, stiffness, dynamic load, and poor weldability. Low hydrogen type electrodes are typically chosen for their good plasticity, high impact toughness, and crack resistance. If the welding position requires a particular electrode, such as a bottom electrode, vertical downward electrode, or other special electrode, it must be utilized. The welding efficiency can be increased by using iron powder electrodes.

Features

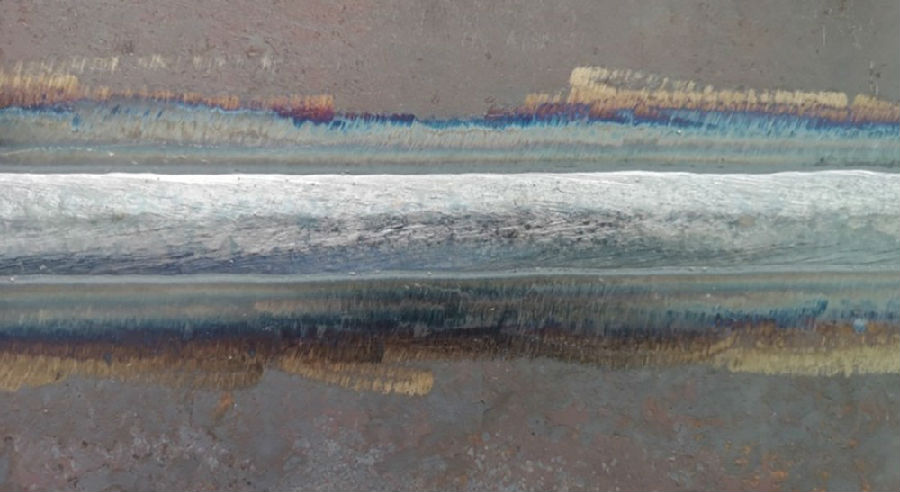

430Mpa grade low carbon steel single and multi-pass welding, suitable for -20°C impact requirement environment, shipbuilding, steel structure, heavy machinery and other uses.

Company & Factory

TYPICAL CASES

Certificates

CHEMICAL COMPONET(%):

| C | Si | Mn | P | S | Ni | Mo | Other |

| 0.057 | 0.32 | 1.02 | 0.023 | 0.007 | - | - | - |

MECHANICAL PROPERTY:

| YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | ELONGATION(%) | IMAPACT VALUE J/℃ | HEATTREAMENT℃xh |

| 404 | 483 | 30 | 85/-20 | AW |