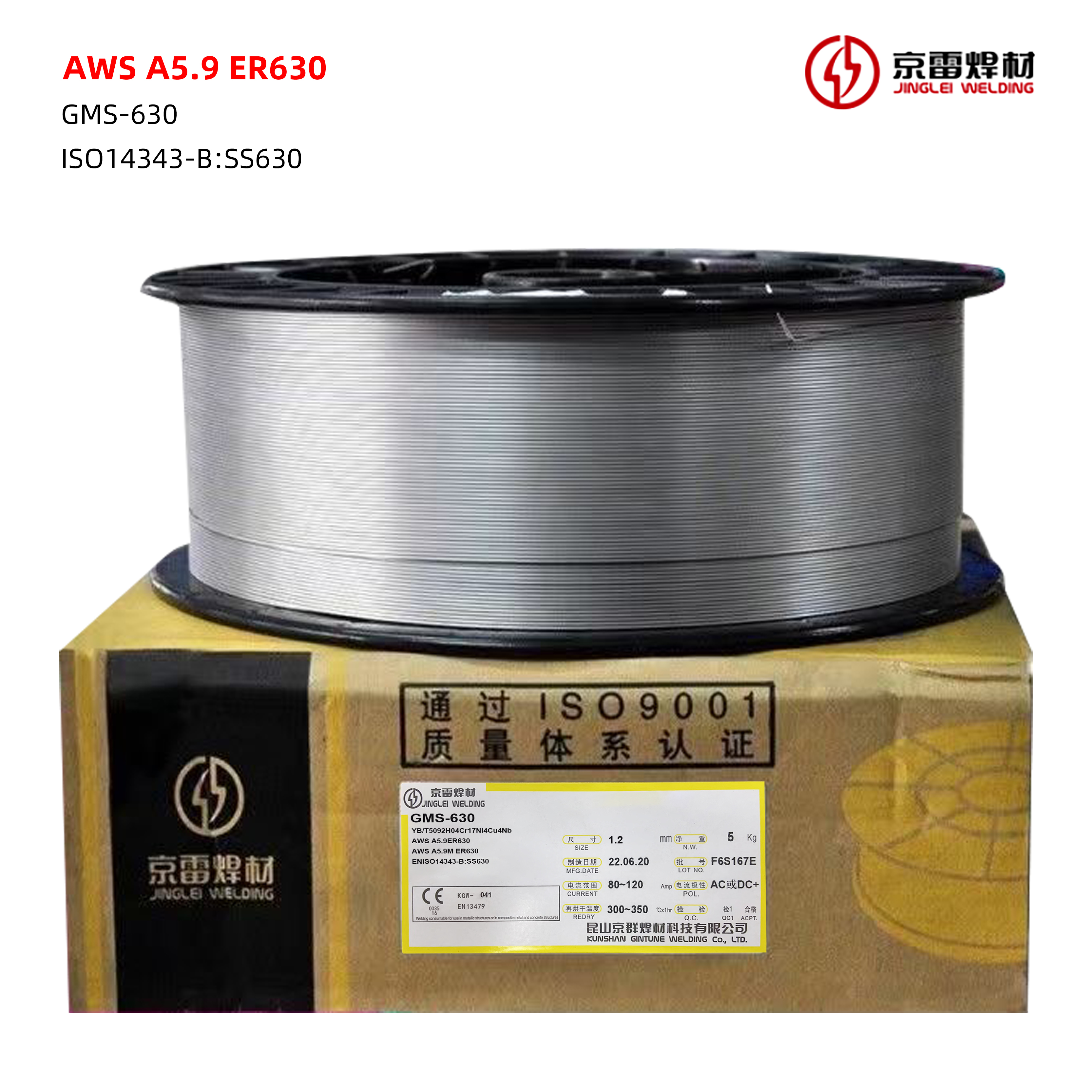

MIG Welding Wire For Stainless Steel ER630 VLCC ship crude oil soldering

WELDING TECHNOLOGY

Don't let the questions

Continue to haunt you

Arc instability

Unsightly molding

Excessive spatter

It is often used for welding golf balls

The mechanical properties of the fused metal are stable

Ripple fine

The X-Ray qualified rate is high, the wire feed is smooth

The arc is stable, the forming is beautiful, the spatter is less, and the welding process has excellent performance.

Easy slagging

Product Parameter

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | P | S | Ni | Cr | Mo | Other |

| GB/T RULES | 0.015 | 0.39 | 0.45 | 0.016 | 0.003 | 4.6 | 16.17 | 0.05 | Nb:0.19 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | Elongation/% | IMAPACT VALUE J/℃ | Heat treatment °C*h | |||||

| GB/T RULES | - | 955 | 17 | - | 1040*1 620*4 | |||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 0.8 | 1.0 | 1.2 | ||||

| ELECTRICITY (Amp) |

H/W | 70-150 | 100-200 | 140-220 | |||

| O/W | 50-120 | 80-150 | 120-180 | ||||

Factory support

The product is suitable for a

wide range of applications

WELDING TECHNOLOGY

-

Carbon steel,

stainless steel tower welding

-

China Global

demethane Tower

-

Xinjiang Kela 2

Central treatment plant project

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | P | S | Ni | Cr | Mo | Other |

| GB/T RULES | 0.015 | 0.39 | 0.45 | 0.016 | 0.003 | 4.6 | 16.17 | 0.05 | Nb:0.19 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | Elongation/% | IMAPACT VALUE J/℃ | Heat treatment °C*h | |||||

| GB/T RULES | - | 955 | 17 | - | 1040*1 620*4 | |||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 0.8 | 1.0 | 1.2 | ||||

| ELECTRICITY (Amp) |

H/W | 70-150 | 100-200 | 140-220 | |||

| O/W | 50-120 | 80-150 | 120-180 | ||||

Write your message here and send it to us