I. Overview

With the rapid development of international chemical and energy logistics, stainless steel storage tanks and containers are widely used in the transportation and storage of chemical, food and beverage, energy and other materials. Due to its excellent low temperature toughness and good corrosion resistance, austenitic stainless steel is widely used in the construction of cryogenic storage tanks, equipment and large cryogenic structures

Cryogenic storage tank

2.Brief introduction of our -196℃ low temperature impact stainless steel welding consumables

|

Category |

Name |

Model |

Standard |

Remark |

|

|

GB/YB |

AWS |

||||

|

Electrode |

GES-308LT |

A002 |

E308L-16 |

E308L-16 |

-196℃≥31J |

|

Flux wire |

GFS-308LT |

- |

TS 308L-F C11 |

E308LT1-1 |

-196℃≥34J |

|

Solid wire |

GTS-308LT (TIG) |

- |

H022Cr21Ni10 |

ER308L |

-196℃≥34J |

|

GMS-308LT (MIG) |

- |

H022Cr21Ni10 |

ER308L |

-196℃≥34J |

|

|

SAW |

GWS-308/ GXS-300 |

- |

S F308L FB-S308L |

ER308L |

-196℃≥34J |

3.Our electrode GES-308LT (E308L-16)

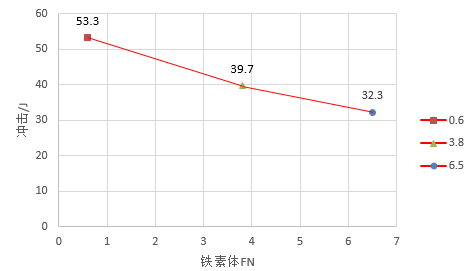

In order to meet the market demand, our company has developed a variety of ultra-low temperature, high toughness austenitic stainless steel electrodes, the chemical composition of the deposited metal (as shown in Table 1) and stable mechanical properties (as shown in Table 2), and has excellent all-position welding process Performance, and excellent low temperature impact toughness, the impact of its ferrite amount on the impact value (Table 3).

1.Chemical composition of deposited metal

|

E308L-16 |

C |

Mn |

Si |

P |

S |

Ni |

Cr |

Mo |

Cu |

N |

Fn |

|

NB (%) |

0.04 |

0.5-2.5 |

1.0 |

0.030 |

0.020 |

9.0-12.0 |

18.0-21.0 |

0.75 |

0.75 |

- |

- |

|

Sample1 |

0.022 |

1.57 |

0.62 |

0.015 |

0.006 |

10.25 |

19.23 |

0.020 |

0.027 |

0.046 |

6.5 |

|

Sample2 |

0.037 |

2.15 |

0.46 |

0.018 |

0.005 |

10.44 |

19.19 |

0.013 |

0.025 |

0.45 |

3.8 |

|

Sample3 |

0.032 |

1.37 |

0.49 |

0.017 |

0.007 |

11.79 |

18.66 |

0.021 |

0.027 |

0.048 |

0.6 |

Table 1

2.Mechanical properties of deposited metal

|

E308L-16 |

Yield MPa |

Tensile MPa |

Elongation % |

-196℃ imparct J/℃ |

GB/T4334-2020 E Intergranular corrosion |

Radiographic inspection |

Remark |

|

|

Single value |

Average value |

|||||||

|

NB |

- |

510 |

30 |

- |

- |

- |

I |

- |

|

Sample1 |

451 |

576 |

42 |

32/32/33 |

32.3 |

qualified |

I |

- |

|

Sample2 |

436 |

563 |

44 |

39/41/39 |

39.7 |

qualified |

I |

- |

|

Sample3 |

412 |

529 |

44.5 |

52/53/55 |

53.3 |

qualified |

I |

- |

Table 2

3.The effect of the amount of deposited metal ferrite on the impact

4.Display of welding process (φ3.2mm)

Upright welding before and after slag removal (DC+)

Pipeline welding before and after slag removal (DC+)

4. Precautions for vertical welding

1. Low current welding should be used;

2. Keep the arc as low as possible;

3. When the arc swings to both sides of the groove, stop for a while, and the swing width is controlled within 3 times the diameter of the electrode.

5.Pipeline picture of welding consumables application

For -196℃ low-temperature impact stainless steel welding consumables, after years of research and development of welding consumables, we already have corresponding supporting welding consumables for welding rods, solid cores, flux cores and submerged arcs, and have developed hand electrode continuous arc welding consumables for all-position welding , and has many engineering application achievements, welcome customers to consult and choose!

Post time: Dec-16-2022