During the hardfacing process, cracks often cause troubles such as rework and customer return. Hardfacing surfacing is different from general structural welding, and the judgment and attention direction of cracks are also quite different. This article analyzes and discusses the common appearance of cracks in the process of hardfacing wear-resistant surfacing.

1. Determination of cracks

At present, domestically and even internationally, there is no general standard for cracks caused by hard surface wear. The main reason is that there are too many types of working conditions for hard surface wear products, and it is difficult to define various Applicable crack judgment criteria under the conditions. However, according to the experience in the application of hard-facing wear-resistant welding materials in various fields, several crack degrees can be roughly sorted out, as well as the acceptance standards in various industries:

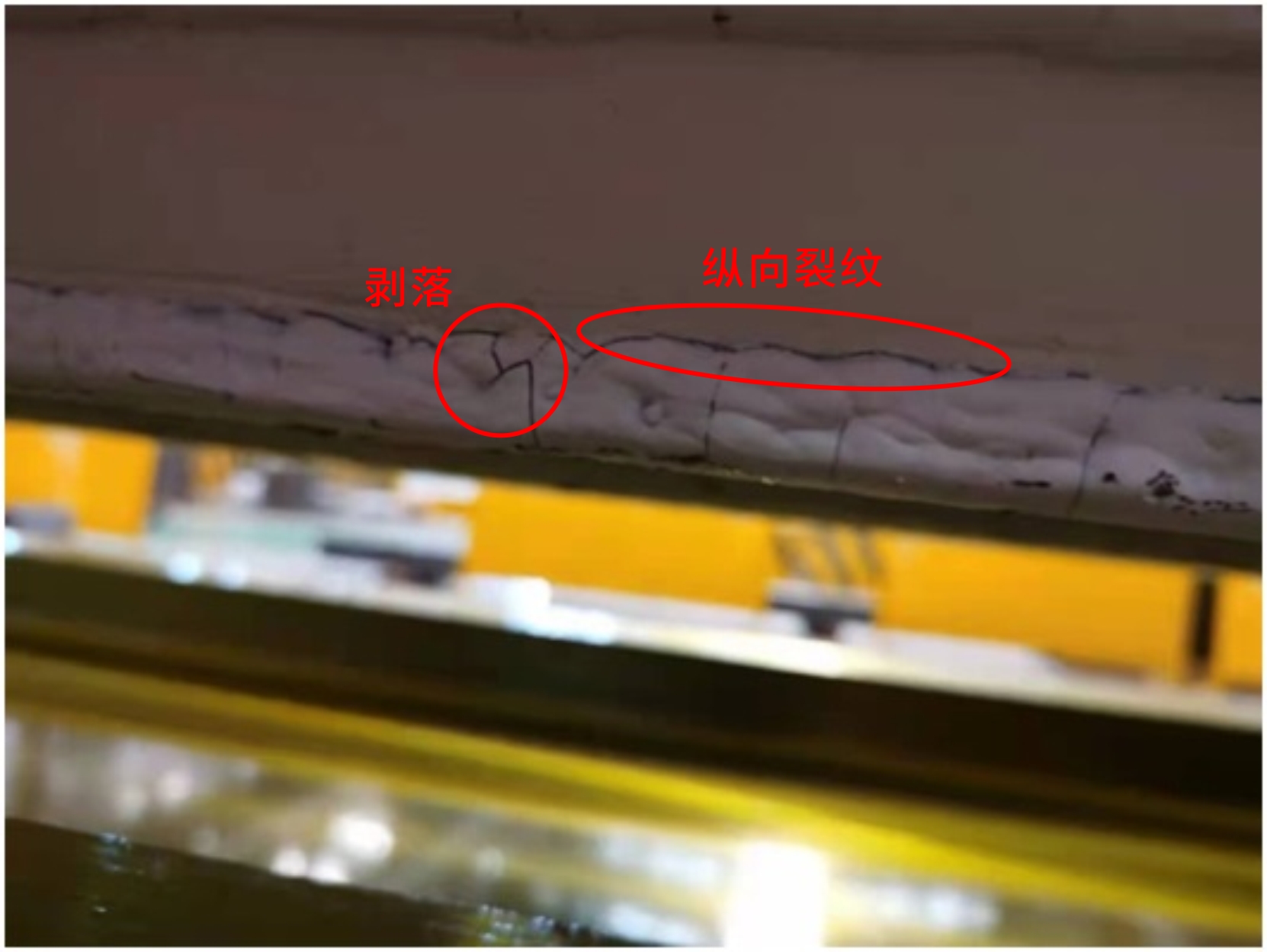

1. The direction of the crack is parallel to the weld bead (longitudinal crack), continuous transverse crack, crack extending to the base metal, spalling

As long as one of the above-mentioned crack levels is met, there is a risk that the entire surfacing layer will fall off. Basically, no matter what the product application is, it is unacceptable and can only be reworked and re-soldered.

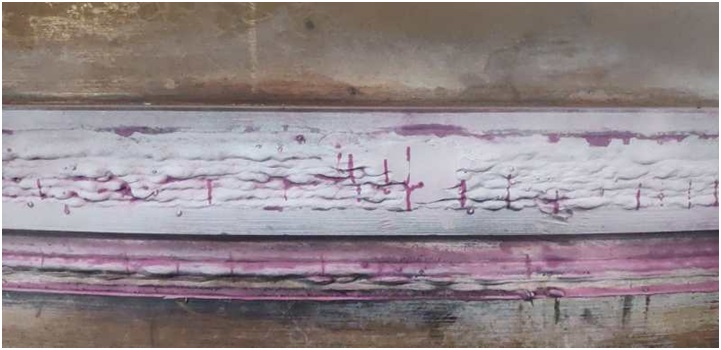

2. There are only transverse cracks and discontinuity

For workpieces that are in contact with solid materials such as ore, sandstone, and coal mines, the hardness is required to be high (HRC 60 or more), and high-chromium welding materials are generally used for surfacing welding. The chromium carbide crystals formed in the weld bead will be produced due to stress release. Cracks are acceptable provided that the crack direction is only perpendicular to the weld bead (transverse) and is discontinuous. However, the number of cracks will still be used as a reference to compare the advantages and disadvantages of welding consumables or surfacing processes.

3. No crack weld bead

For workpieces such as flanges, valves, and pipes, where the main contact substances are gases and liquids, the requirements for cracks in the weld bead are more cautious, and it is generally required that the appearance of the weld bead should not have cracks.

Slight cracks on the surface of workpieces such as flanges and valves need to be repaired or reworked

Use our company's GFH-D507Mo valve special welding consumables for surfacing, no cracks on the surface

2. The main causes of hard surface wear-resistant surfacing cracks

There are many factors that cause cracks. For hard surface wear-resistant surfacing welding, it can be mainly divided into hot cracks that can be found after the first or second pass, and cold cracks that appear after the second pass or even after all welding.

Hot crack:

During the welding process, the metal in the weld seam and heat-affected zone cools to the high-temperature zone near the solidus line to produce cracks.

Cold crack:

Cracks generated at temperatures below the solidus (approximately at the martensitic transformation temperature of steel) mainly occur in medium-carbon steels and high-strength low-alloy steels and medium-alloy steels.

As the name suggests, hard surface products are known for their high surface hardness. However, the pursuit of hardness in mechanics also results in a decrease in plasticity, that is, an increase in brittleness. Generally speaking, surfacing above HRC60 does not pay much attention to the thermal cracks generated during the welding process. However, hard surfacing welding with a hardness between HRC40-60, if there is a requirement for cracks, The intergranular cracks in the welding process or the liquefaction and multilateral cracks caused by the upper weld bead to the heat-affected zone of the lower weld bead are very troublesome.

Even if the problem of hot cracks is well controlled, the threat of cold cracks will still be faced after surfacing welding, especially the highly brittle material such as hard surface weld bead, which is more sensitive to cold cracks. Severe cracking is mostly caused by cold cracks

3. Important factors affecting wear-resistant cracks on hard surfaces and strategies to avoid cracks

The important factors that can be explored when cracks occur in the hard surface wear process are as follows, and corresponding strategies are proposed for each factor to reduce the risk of cracks:

1. Base material

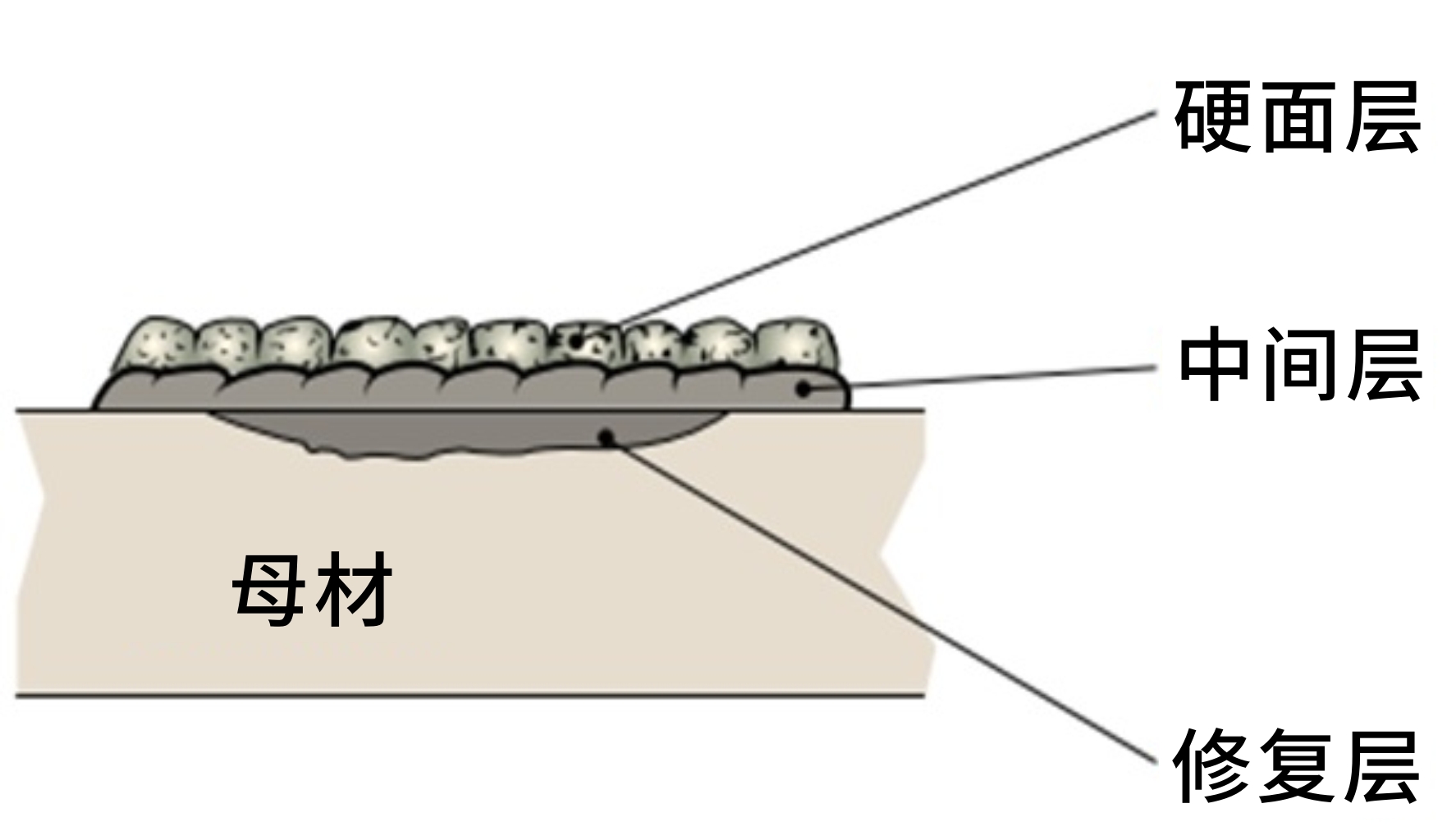

The influence of the base metal on hard surface wear-resistant surfacing is very important, especially for workpieces with less than 2 layers of surfacing welding. The composition of the base metal directly affects the properties of the weld bead. Material selection is a detail that needs to be paid attention to before starting work. For example, if a valve workpiece with a target hardness of about HRC30 is surfacing with a cast iron base material, it is recommended to use a welding material with a slightly lower hardness, or add a layer of stainless steel intermediate layer, so as to avoid the carbon content in the base material from increasing the risk of weld bead cracks.

Add an intermediate layer on the base material to reduce the risk of cracking

2. Welding consumables

For the process that requires no cracks, high-carbon and high-chromium welding consumables are not suitable. It is recommended to use martensitic system welding consumables, such as our GFH-58. It can weld a crack-free bead surface when the hardness is as high as HRC58~60, especially suitable for non-planar workpiece surfaces that are highly abrasive by soil and stone.

3. Heat input

On-site construction tends to use higher current and voltage due to the emphasis on efficiency, but moderately reducing the current and voltage can also effectively reduce the occurrence of thermal cracks.

4. Temperature control

Multi-layer and multi-pass hardfacing welding can be regarded as a process of continuous heating, cooling and reheating for each pass, so temperature control is very important, from preheating before welding to pass temperature during surfacing Control, and even the cooling process after welding, require great attention.

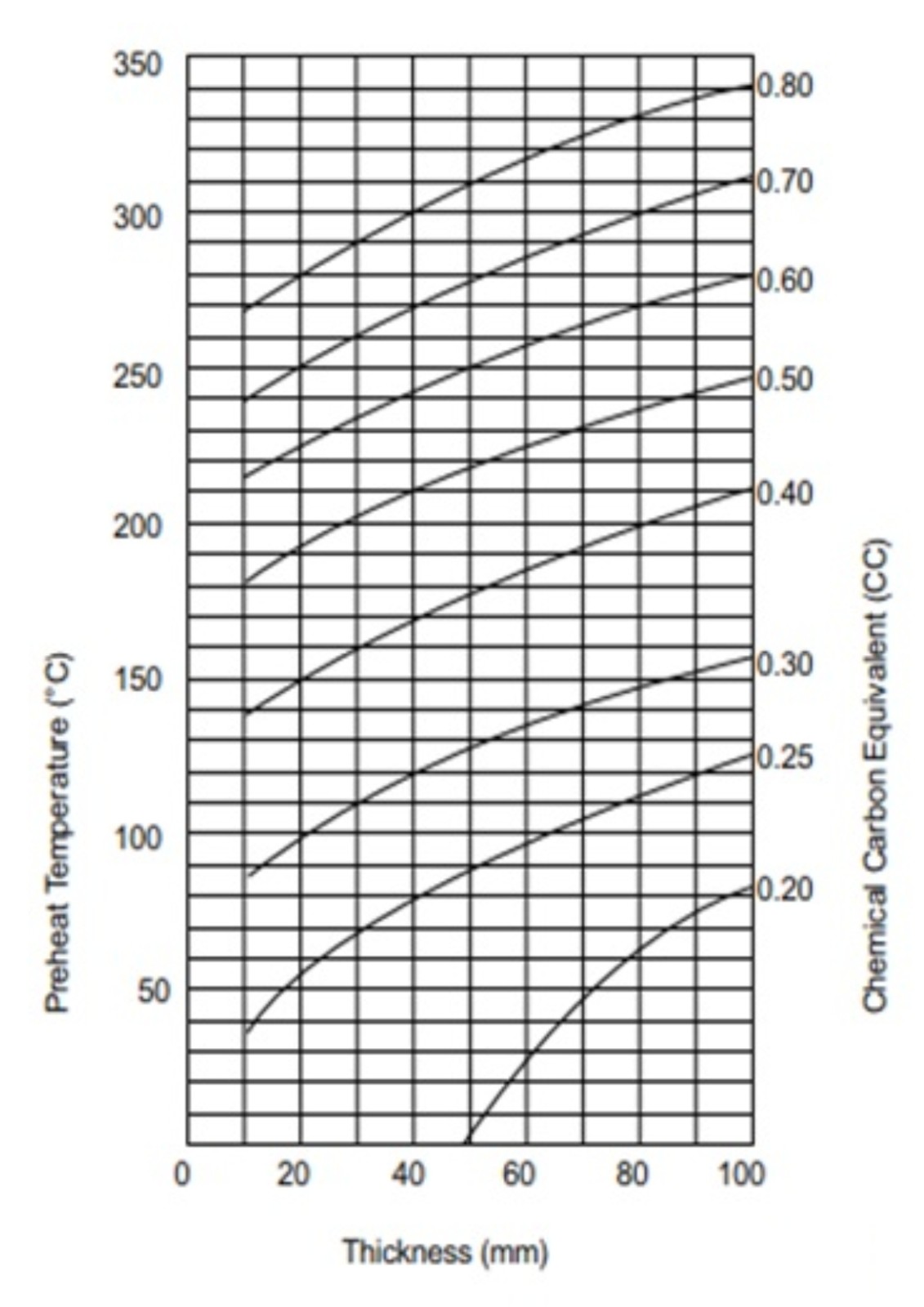

The preheating and track temperature of surfacing welding are closely related to the carbon content of the substrate. The substrate here includes the base material or intermediate layer, and the bottom of the hard surface. Generally speaking, due to the carbon content of the hard surface deposited metal If the content is high, it is recommended to maintain the road temperature above 200 degrees. However, in actual operation, due to the long length of the weld bead, the front part of the weld bead has been cooled by the end of one pass, and the second pass will easily produce cracks in the heat-affected zone of the substrate. Therefore, in the absence of proper equipment to maintain the channel temperature or preheat before welding, it is recommended to operate in multiple sections, short welds, and continuous surfacing welding in the same section to maintain the channel temperature.

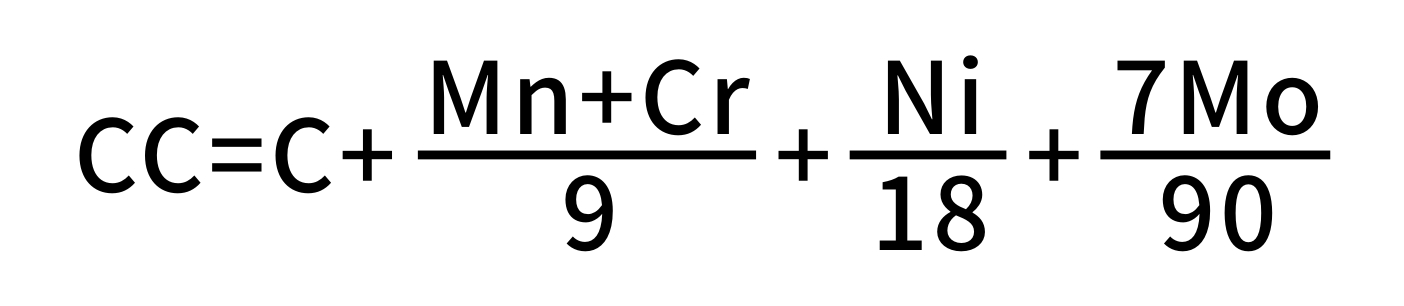

Relationship between carbon content and preheating temperature

The slow cooling after surfacing is also a very critical but often neglected step, especially for large workpieces. Sometimes it is not easy to have appropriate equipment to provide slow cooling conditions. If there is really no way to solve this situation, we can only recommend using it again The method of segmented operation, or avoid surfacing welding when the temperature is low, to reduce the risk of cold cracks.

Four. Conclusion

There are still many individual manufacturers' differences in the requirements of hardfacing for cracks in practical applications. This article only makes a rough discussion based on limited experience. Our company's hard surface wear-resistant series of welding consumables have corresponding products for customers to choose for various hardness and applications. Welcome to consult with the business in each district.

Application of wear-resistant composite board factory

|

Item |

Protect gas |

size |

Main |

HRC |

Using |

|

GFH-61-0 |

Self protect |

1.6 2.8 3.2 |

C:5.0 Si:0.6 Mn:1.2 Cr:28.0 |

61 |

Suitable for grinding wheels, cement mixers, bulldozers, etc. |

|

GFH-65-0 |

Self protect |

1.6 2.8 3.2 |

C:5.0 Cr:22.5 Mo:3.2 V:1.1 W:1.3 Nb:3.5 |

65 |

Suitable for high temperature dust removal fan blades, blast furnace feeding equipment, etc. |

|

GFH-70-O |

Self protect |

1.6 2.8 3.2 |

C:5.0 Cr:30.0 B:0.3 |

68 |

Applicable to coal roller, ghost red, receiving gear, blast coal cover, grinder, etc. |

Application in cement industry

|

Item |

Protect gas |

size |

Main |

HRC |

Using |

|

GFH-61-0 |

Self protect |

1.6 2.8 3.2 |

C:5.0 Si:0.6 Mn:1.2 Cr:28.0 |

61 |

Suitable for grinding stone rollers, cement mixers, etc |

|

GFH-65-0 |

Self protect |

1.6 2.8 3.2 |

C:5.0 Cr:22.5 Mo:3.2 V:1.1 W:1.3 Nb:3.5 |

65 |

Suitable for high temperature dust removal fan blades, blast furnace feeding equipment, etc. |

|

GFH-70-O |

Self protect |

1.6 2.8 3.2 |

C:5.0 Cr:30.0 B:0.3 |

68 |

Suitable for grinding stone rollers, ghost teeth, receiving teeth, grinders, etc. |

|

GFH-31-S |

GXH-81 |

2.8 3.2 |

C:0.12 Si:0.87 Mn:2.6 Mo:0.53 |

36 |

Applicable to metal-to-metal wear parts such as crown wheels and axles |

|

GFH-17-S |

GXH-81 |

2.8 3.2 |

C:0.09 Si:0.42 Mn:2.1 Cr:2.8 Mo:0.43 |

38 |

Applicable to metal-to-metal wear parts such as crown wheels and axles |

Steel Plant Application

|

Item |

Protect gas |

size |

Main |

HRC |

Using |

|

GFH-61-0 |

Self protect |

1.6 2.8 3.2 |

C:5.0 Si:0.6 Mn:1.2 Cr:28.0 |

61 |

Suitable for sintering plant furnace bars, ghost teeth, wear-resistant plates, etc. |

|

GFH-65-0 |

Self protect |

1.6 2.8 3.2 |

C:5.0 Cr:22.5 Mo:3.2 V:1.1 W:1.368 Nb:3.5 |

65 |

|

|

GFH-70-0 |

Self protect |

1.6 2.8 3.2 |

C:5.0 Cr:30.0 B:0.3 |

68 |

|

|

GFH-420-S |

GXH-81 |

2.8 3.2 |

C:0.24 Si:0.65 Mn:1.1 Cr:13.2 |

52 |

Suitable for casting rolls, conveying rolls, steering rolls, etc. in continuous casting plants and hot rolling plants |

|

GFH-423-S |

GXH-82 |

2.8 3.2 |

C:0.12 Si:0.42 Mn:1.1 Cr:13.4 Mo:1.1 V:0.16 Nb:0.15 |

45 |

|

|

GFH-12-S |

GXH-81 |

2.8 3.2 |

C:0.25 Si:0.45 Mn:2.0 Cr:5.8 Mo:0.8 V:0.3 W:0.6 |

51 |

Anti-adhesive wear properties, suitable for steel plate factory steering rolls, pinch rolls and wear parts between metals |

|

GFH-52-S |

GXH-81 |

2.8 3.2 |

C:0.36 Si:0.64 Mn:2.0 Ni:2.9 Cr:6.2 Mo:1.35 V:0.49 |

52 |

Miner Application

|

Item |

Protect gas |

size |

Main |

HRC |

Using |

|

GFH-61-0 |

Self protect |

1.6 2.8 3.2 |

C:5.0 Si:0.6 Mn:1.2 Cr:28.0 |

61 |

Applicable to excavators, roadheaders, picks, etc. |

|

GFH-58 |

CO2 |

1.6 2.4 |

C:0.5 Si:0.5 Mn:0.95 Ni:0.03 Cr:5.8 Mo:0.6 |

58 |

Suitable for surfacing welding on the side of the stone delivery trough |

|

GFH-45 |

CO2 |

1.6 2.4 |

C:2.2 Si:1.7 Mn:0.9 Cr:11.0 Mo:0.46 |

46 |

Suitable for wearing parts between metals |

Valve application

|

Item |

Protect gas |

size |

Main |

HRC |

Using |

|

GFH-D507 |

CO2 |

1.6 2.4 |

C:0.12 S:0.45 Mn:0.4 Ni:0.1 Cr:13 Mo:0.01 |

40 |

Suitable for surfacing welding of valve sealing surface |

|

GFH-D507Mo |

CO2 |

1.6 2.4 |

C:0.12 S:0.45 Mn:0.4 Ni:0.1 Cr:13 Mo:0.01 |

58 |

Suitable for surfacing welding of valves with high corrosiveness |

|

GFH-D547Mo |

Manual rods |

2.6 3.2 4.0 5.0 |

C:0.05 Mn:1.4 Si:5.2 P:0.027 S:0.007 Ni:8.1 Cr:16.1 Mo:3.8 Nb:0.61 |

46 |

Suitable for high temperature, high pressure valve surfacing welding |

More information send to E-mail: export@welding-honest.com

Post time: Dec-26-2022