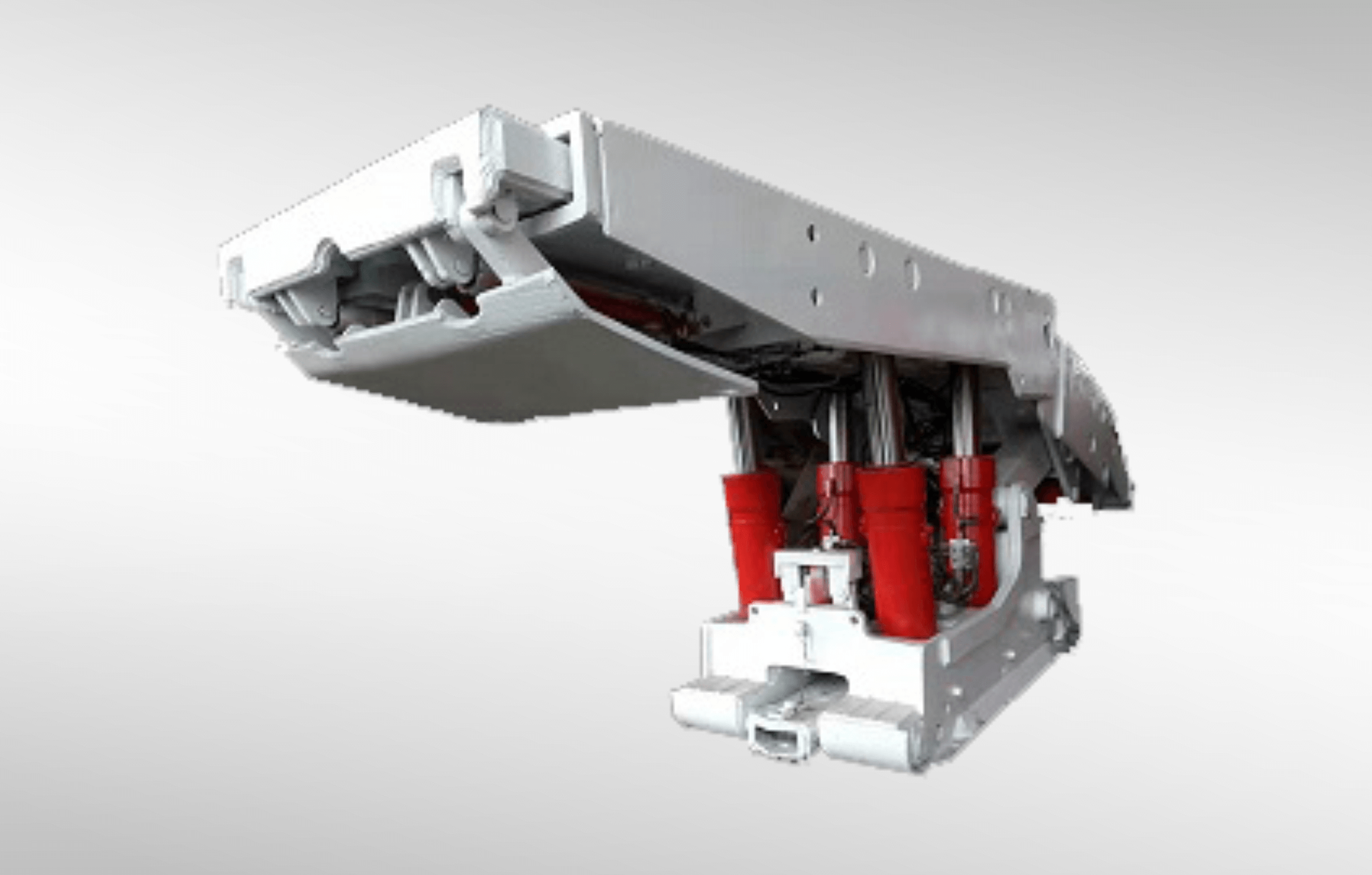

With the rapid development of construction machinery manufacturing and the popularization of lightweight design of steel structural parts, Q890 high-strength steel plates are gradually applied to steel structural parts such as coal mine hydraulic supports, heavy vehicles, and construction machinery, and are mostly used in mines and various engineering constructions. Drilling rigs, electric shovels, electric wheel dump trucks, mining vehicles, excavators, loaders, bulldozers, various types of cranes and other mechanical equipment.

Q890 high-strength steel base material (GB T 16270-2009)

1.Chemical composition of base material

|

Model |

Q890C |

Q890D |

Q890E |

Q890F |

|

|

Metal Wt% |

C |

0.20 |

|||

|

Si |

0.80 |

||||

|

Mn |

2.00 |

||||

|

P |

0.025 |

0.020 |

|||

|

S |

0.015 |

0.010 |

|||

|

Cu |

0.50 |

||||

|

Cr |

1.50 |

||||

|

Ni |

2.00 |

||||

|

Mo |

0.70 |

||||

|

B |

0.005 |

||||

|

V |

0.12 |

||||

|

Nb |

0.06 |

||||

|

Ti |

0.05 |

||||

2.Mechanical properties of base metal

|

Model |

Q890C |

Q890D |

Q890E |

Q890F |

|||

|

Metal Wt% |

Thickness mm |

≤50 |

Yield Strength Mpa |

890 |

|||

|

>50-100 |

830 |

||||||

|

>100-150 |

- |

||||||

|

Thickness mm |

≤50 |

tensile strength Mpa |

940-1100 |

||||

|

>50-100 |

880-1100 |

||||||

|

>100-150 |

- |

||||||

|

elongation after break % |

11 |

||||||

|

Impact absorption energy J/℃ |

34/0 |

24/-20 |

27/-40 |

27/-60 |

|||

Supporting welding consumables

|

Wire category |

Copper-free solid wire |

Metal powder cored wire |

|

product name |

GMR-W80 |

GCR-130GM |

|

Executive standard |

AWS A5.28 ER120S-G |

- |

3.Typical composition (deposited metal 80%Ar+20%CO2)

|

Model |

GMR-W80 |

GCR-130GM |

|

|

Metal Wt% |

C |

0.08 |

0.06 |

|

Mn |

1.81 |

1.92 |

|

|

Si |

0.79 |

0.33 |

|

|

Ni |

2.36 |

2.70 |

|

|

Cr |

4.Typical mechanical properties (80%Ar+20%CO2)

0.35 |

0.54 |

|

|

Mo |

0.60 |

0.50 |

|

|

P |

0.007 |

0.008 |

|

|

S |

0.009 |

0.005 |

|

|

Note |

filler metal |

deposited metal |

|

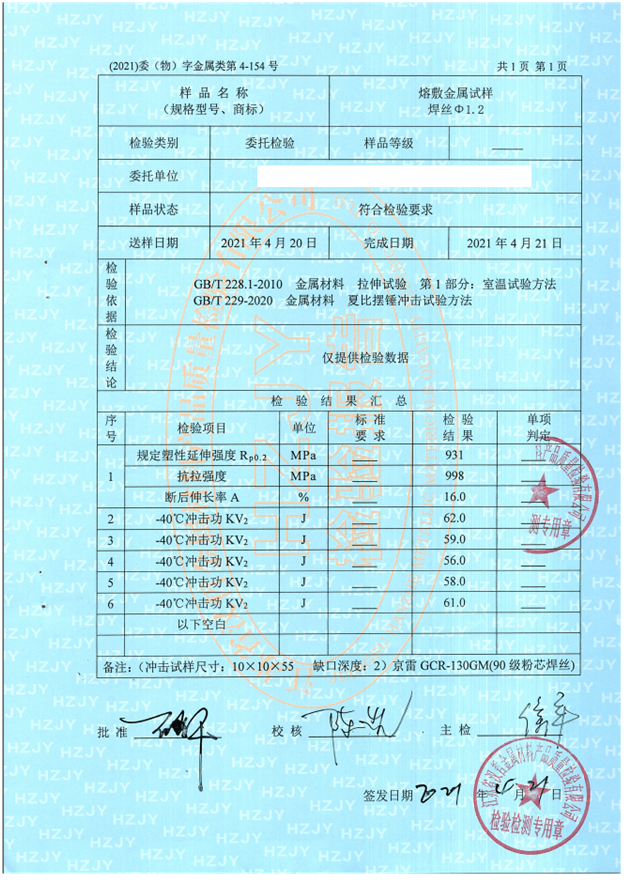

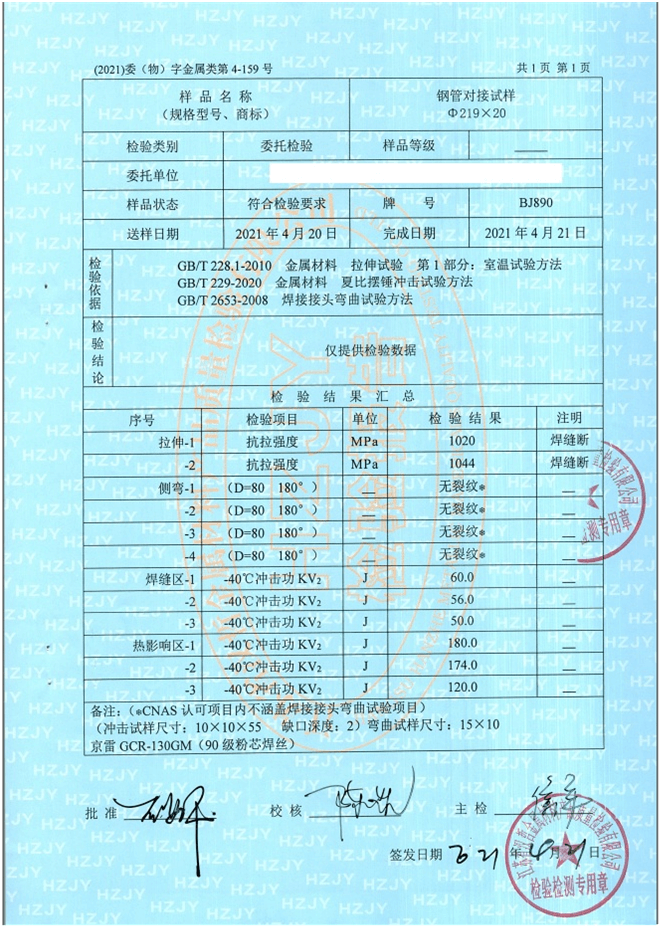

4.Typical mechanical properties (80%Ar+20%CO2)

|

Name |

GMR-W80 |

GCR-130GM |

|

Yield Strength Mpa |

900 |

930 |

|

tensile strength Mpa |

950 |

990 |

|

elongation after break % |

17 |

16 |

|

Impact absorption energy J/℃ |

80/-40 |

60/-40 |

6.Recommended welding parameters

|

Name |

GMR-W80 |

GCR-130GM |

|

|

Weld specification |

electric current A |

260±20 |

270±20 |

|

Voltage V |

27±1 |

28±1 |

|

|

welding speed Mm/min |

350±50 |

350±50 |

|

|

Temporature ℃ |

150±15 |

150±15 |

|

For the wide application of Q890 high-strength steel, after years of research and development of welding consumables, we have two series of corresponding supporting welding consumables, solid and metal powder core, and have many engineering application achievements. Welcome customers to consult and choose!

More information send to E-mail: export@welding-honest.com

Post time: Jan-18-2023