In 2010, South Korea’s POSCO, Daewoo Shipbuilding and the world’s five major classification societies started the project of “joint development of high manganese steel and welding materials for ultra-low temperature”, and achieved mass production of high manganese steel for LNG storage tanks in 2015. By June 2022, to break through the technical bottleneck, South Korea’s Daewoo Shipbuilding & Marine Engineering (DSME) and POSCO will hold the first in the world to install high-manganese steel LNG fuel storage tanks on LNG-powered very large crude carriers (VLCCs) Ceremony, and said that it has developed fuel tank manufacturing technology from steel pretreatment to welding and forming.

1. What is high manganese steel?

High manganese steel for LNG storage tanks is an alloy steel with manganese content between 22-25%, which has good low temperature resistance and high wear resistance, which is more obvious than traditional LNG storage tank materials It is the new darling of LNG storage tank materials that South Korea has devoted to research and development for more than ten years.

2.Brief analysis of steel types and their advantages and disadvantages for LNG storage tanks Our matching welding consumables can meet these stringent requirements: Since large LNG fuel storage tanks are the core equipment of environmentally friendly fuel-powered ships and the entire LNG industry chain, the technical standards are extremely strict and the cost is expensive. LNG is usually stored and transported under the ultra-low temperature environment of -163°C. The “International Code for the Construction and Equipment of Ships Carrying Liquefied Gases in Bulk” is referred to as the “IGC Code”. The four low-temperature materials that can be used for LNG construction include: aluminum alloy steel, Austria Tensitic stainless steel, austenitic Fe-Ni alloy steel (also known as Invar steel) and 9%Ni steel (see Table 1 for details), while 9%Ni steel is the most commonly used and widely used for LNG fuel storage tanks. But the disadvantages are that the price is still high, the processing procedures are cumbersome, the strength is relatively low, and the nickel content in the product is high. In recent years, the nickel price has continued to rise, and the product cost has increased significantly.

4 cryogenic materials that can be used in LNG construction under the “IGC Code”

|

Minimum design temperature |

Main steel types and heat treatment |

Impact test temperature |

|

-165℃ |

9%Ni steel NNT or QT |

-196℃ |

|

austenitic stainless steel – 304, 304L, 316/316L, 321 and 347 solution treated |

-196℃ |

|

|

Aluminum alloy – 5083 annealed |

NO |

|

|

austenitic iron-nickel alloy (36%Ni) |

Strength comparison between commonly used LNG materials and new high manganese steel

|

Item |

Commonly alloy |

high manganese steel |

||||

|

9% Ni steel |

304 S.S |

Alu 5083-O |

Invar steel |

MC |

||

|

Base materials |

Chemical Composition |

Fe-9Ni |

Fe-18.5Cr-9.25Ni |

Al-4.5Mg |

Fe-36Ni |

M C-H mn |

|

Microstructure |

α1(+Y) |

γ(FCC) |

FCC |

FCC |

FCC |

|

|

Yield Strength Mpa |

≥585 |

≥205 |

124-200 |

230-350 |

≥400 |

|

|

Tensile Strength Mpa |

690-825 |

≥515 |

276-352 |

400-500 |

800-970 |

|

|

-196℃ Impact J |

≥41 |

≥41 |

NO |

NO |

≥41 |

|

|

Weldments |

welding consumables |

Inconal |

Type308 |

ER5356 |

- |

FCA,SA,GTA |

|

Yield Strength Mpa |

- |

- |

- |

- |

≥400 |

|

|

Tensile Strength Mpa |

≥690 |

≥550 |

- |

- |

≥660 |

|

|

-196℃ Impact J |

≥27 |

≥27 |

- |

- |

27 |

|

Ultra-low temperature high-manganese steel, which combines high strength, high toughness, and low cost, has a very broad application prospect in the future LNG fuel storage tank and environmental protection alternative fuel storage tank markets such as liquid ammonia, liquid hydrogen, and methanol.

Composition and performance requirements of high manganese steel

Chemical Composition (ASTM Draft)

|

|

C |

Mn |

p |

s |

Cr |

Cu |

|

% |

0.35-0.55 |

22.5-25.5 |

<0.03 |

<0.01 |

3.0-4.0 |

0.3-0.7 |

Mechanical behavior

● Crystal structure: face centered cubic lattice (γ-Fe)

● Permissible temperature>-196℃

● Yield strength>400MPa (58ksi)

● Tensile strength: 800~970MPa (116-141ksi)

● Charpy V-notch impact test >41J at -196℃(-320℉)

Introduction of our company’s high manganese steel matching welding consumables

In recent years, we have devoted ourselves to the research and development of high-manganese steel matching welding consumables for LNG storage tanks, and successfully developed welding consumables that can match the properties of high-manganese steel base materials for LNG storage tanks. The specific properties are shown in Table 2.

Mechanical properties of high manganese steel matching welding consumables deposited metal

|

Name |

Position |

mechanical properties |

||||

|

YP |

TS |

EL |

-196℃impact |

radiographic tests |

||

|

Design goals |

≥400 |

≥660 |

≥25 |

≥41 |

I |

|

|

GER-HMA Φ3.2mm |

Manual electrode |

488 |

686 |

46.0 |

73.3 |

I |

|

GCR-HMA-S Φ3.2mm |

Metal cored wire |

486 |

700 |

44.5 |

62.0 |

I |

Ps.Metal powder core submerged arc welding wire for high manganese steel adopts matching flux GXR-200 for high manganese steel

Weldability and sample display of high manganese steel welding consumables for LNG storage tanks

The weldability of welding consumables for high manganese steel is shown as follows

Electrode (GER-HMA) flat fillet welding after slag removal

Electrode (GER-HMA) elevation angle welding after slag removal

Welding rod (GER-HMA) before and after fillet welding slag removal

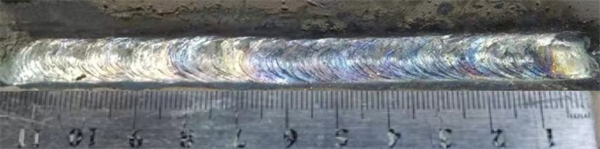

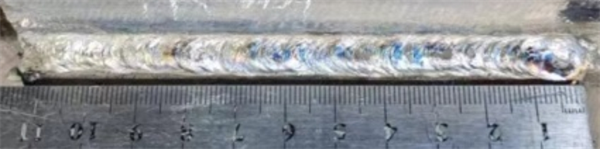

Metal powder core submerged arc (GCR-HMA-S) weld display

The samples of high manganese steel welding rod welding joints are shown as follows

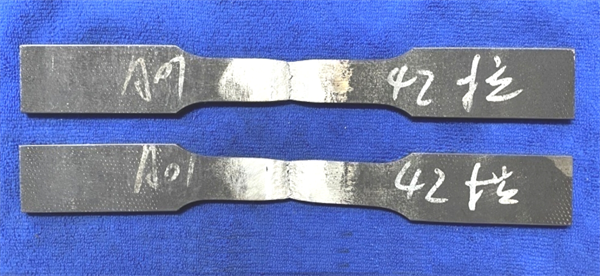

Flat welding (1G) tensile sample display

Vertical welding (3G) tensile sample display

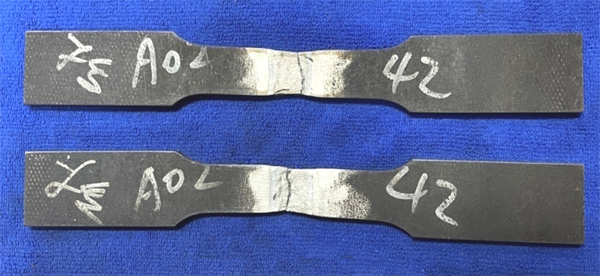

Flat welding (1G) bending sample display

Flat welding (1G) bending sample display

PS.High manganese steel is welded with welding rods 1G and 3G, no cracks in the face bending and back bending samples, and the crack resistance is good

Post time: Nov-22-2022