Tower is used for distillation, purification, absorption, distillation and other chemical equipment, most of the tower devices need to contact acid, alkali, salt, organic solvents and other corrosive media, so it is necessary to surfacing a large area of corrosion resistant layer in the cylinder and sealing parts. As an efficient way of surfacing, strip surfacing is widely used in tower welding of chemical equipment.

The traditional electrode surfacing technology is double-layer submerged arc surfacing technology with transition layer and corrosion resistant layer, but this technology has long manufacturing cycle and high manufacturing cost. In order to solve this problem, JingQunCo has developed single-layer surfacing welding materials (GDS-309LA welding strip, GXS-ED308L electroslag flux), which can achieve the effect of two-layer surfacing with only single-layer surfacing, and can simplify the surfacing process from two-layer surfacing to one-layer surfacing.

Introduction of the welding materials

1.The Chemical component

|

Rules/Name |

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Note |

|

NB/T47018.5 EQ309LA |

≤0.030 |

≤1.00 |

0.5-2.5 |

≤0.025 |

≤0.015 |

21.0-23.0 |

9.0-12.0 |

solder strip |

|

GDS-309LA |

0.018 |

0.34 |

1.90 |

0.017 |

0.001 |

21.96 |

11.17 |

solder strip |

| Rules/Name | NB/T47018.5 FZ308-D |

GDS-309LA+GXS-ED308L solder strip+ Flux combination |

|||

| C | ≤0.05 | 0.028 | 0.028 | 0.029 | 0.029 |

| Si | ≤1.00 | 0.58 | 0.64 | 0.62 | 0.64 |

| Mn | ≤2.5 | 1.33 | 1.33 | 1.35 | 1.33 |

| P | ≤0.030 | 0.018 | 0.018 | 0.018 | 0.017 |

| S | ≤0.020 | 0.004 | 0.004 | 0.004 | 0.004 |

| Cr | 18.0-21.0 | 18.21 | 18.47 | 18.39 | 18.28 |

| Ni | 8.0-11.0 | 10.12 | 10.31 | 10.27 | 10.30 |

| Note | deposited metal | Welding surface | Under surface 1mm | Under surface 2mm | Under surface 3mm |

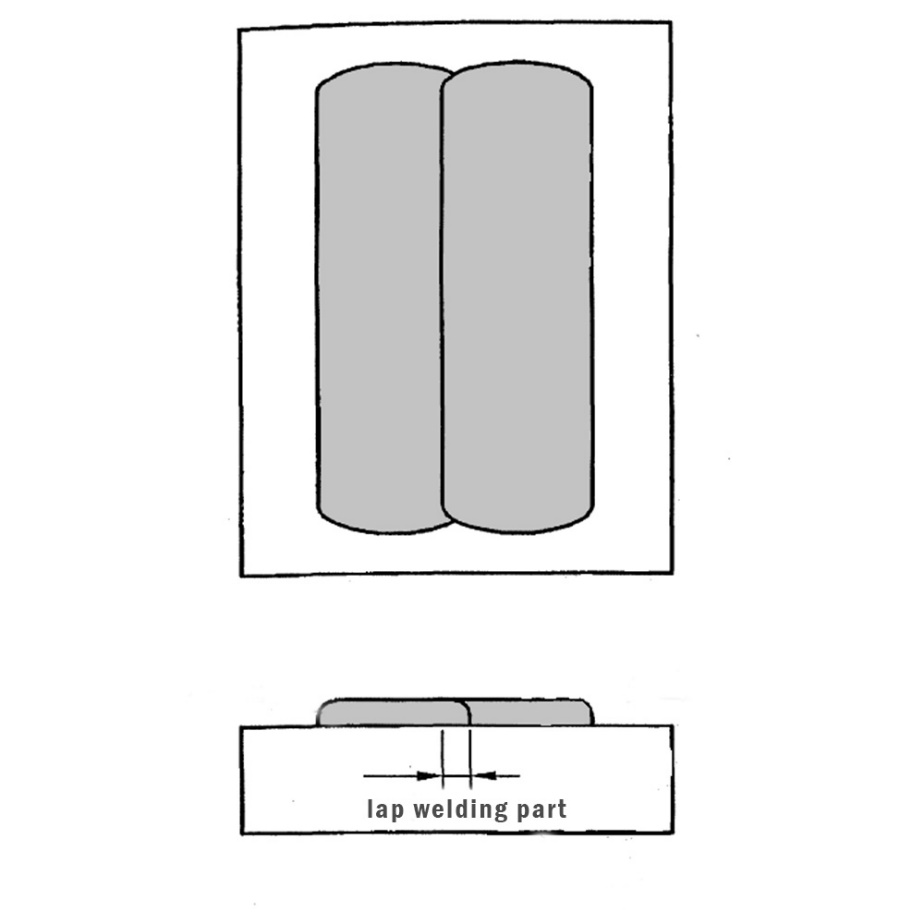

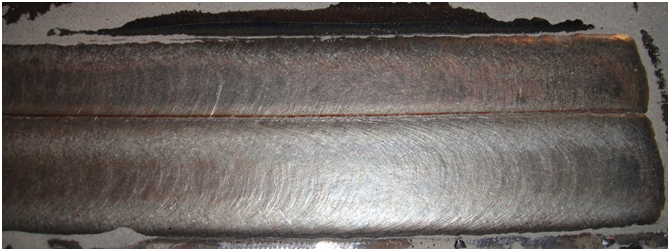

2.Weld appearance

Recommended welding parameters

| Specification(mm) | 0.5*60 |

| Electricity(A) | 850-950 |

| Voltage(V) | 26-30 |

| Welding Speed(mm/min) | 150 |

| Length(mm) | 35-40 |

| Lap welding(mm/min) | 6-10 |

| Thickness of flux spread(mm/min) | About 25 |

Weld pass thickness: about 4.7mm

Weld width: about 62.5mm

Weld pass appearance: beautiful shape, weld surface is flat, lap transition is smooth.

3.Mechanical capacity

Ferrite content (welded state)

| Solder strip+ Flux combination | GDS-309LA+GXS-ED308L |

| Measured value | The ferrite content is about 7FN, and the ferrite percentage content is about 8% |

| Measuring position | Weld surface |

Test method: GB/T 1954-2008 "chromium-nickel austenitic stainless steel weld ferrite content measurement method"

Bending test:

as

620℃*20h

Test results: lateral bending, indenter diameter 4T (40mm), bending Angle 180° without crack.

Intergranular corrosion test

As welded

620℃*20h

Test method: GB/T 4334-2020 Method E

Test solution: copper - copper sulfate -16% sulfuric acid

Test results: No intergranular corrosion crack

Micro metallography of surfacing layer

As welded

As welded

620℃*20h heat treatment

620℃*20h heat treatment

Engineering application

1.Customer welding process evaluation process

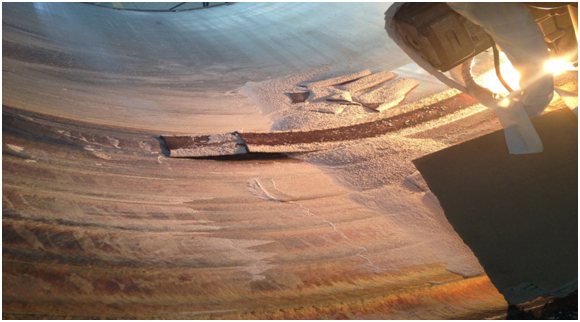

2.Customer site construction

After years of research and development, Jingqun single-layer electroslag surfacing welding material performance is stable and reliable, has many engineering application achievements.

Welcome customers to consult and choose!

More information add whatsapp+86 13252436578

E-Mail:sale@welding-honest.com

Post time: Nov-04-2022