G115 steel is a new type of heat-resistant steel material with excellent high-temperature performance independently developed in China, which is mainly used in the manufacture of large-diameter thick-walled pipes and other heat-resistant parts at 630~650 °C, and is the key material to improve the efficiency level of coal-fired thermal power units.

Since 2016, we have been continuously developing and optimizing the welding consumables for G115 steel, and have worked closely with various research institutions and users in this process, and achieved fruitful results. In August 2020, he successfully assisted in holding the "G115 Heat-resistant Steel Welding Process Technology Seminar" in Kunshan, after which the minutes of the meeting were formed (see the figure below), and important guiding documents such as "G115 Steel Welding Process Evaluation Performance Qualified Indicators" and "G115 Steel Welding Process Route and Key Parameters" were formulated.

After clarifying the performance requirements and parameter details at the meeting, we continued to invest more in development, and have developed a full range of welding materials for G115 with excellent welding process (electrode and TIG welding wire can meet the full position welding), stable performance, and meet the requirements of various performance indicators set by the meeting. The specific models and characteristics are shown in Table 1 below.

List of the main welding consumables for G115 steel

|

ITEM |

PRODUCT NAME |

FEATURE |

|

Manual rod |

GER-93 |

Core wire transition type electrode, the main component is 9% Cr-3% W-3% Co-Cu-V-Nb-B, stable impact resistance at room temperature, and there is a margin |

|

GTAW wire |

GTR-W93 |

The main ingredients are the same as above, for priming, stable performance and good workmanship |

|

Argon free back protection GTWA rods |

GTR-E93 |

Coated argon arc welding wire, the back side can be free of argon filling, double-sided molding is excellent |

|

SAW wire |

GWR-W93 |

The weld bead is formed well, the flaw detection qualification rate is high, and the impact performance is stable |

|

Flux |

GXR-93 |

At the same time, we actively carry out technical exchanges, welding consumables performance testing and process exchanges with various user units, and seek opportunities for G115 tube assessment to fully verify the compliance of welding consumables to the actual process.

In February 2022, Guangdong Thermal Power Welding Company evaluated our G115 steel welding rod (product name: GER-93) for 115mm thick pipe welding process.

The following is a brief demonstration of the assessment process:

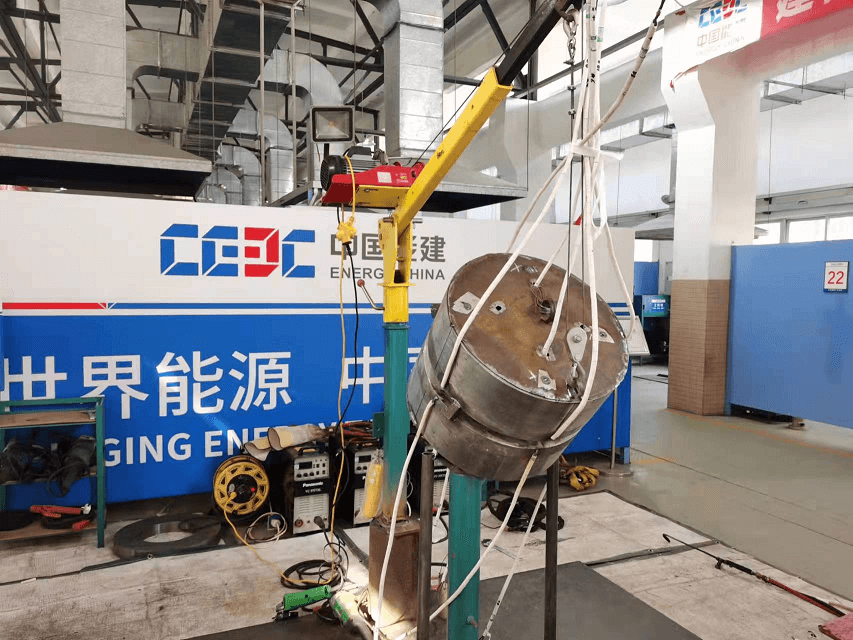

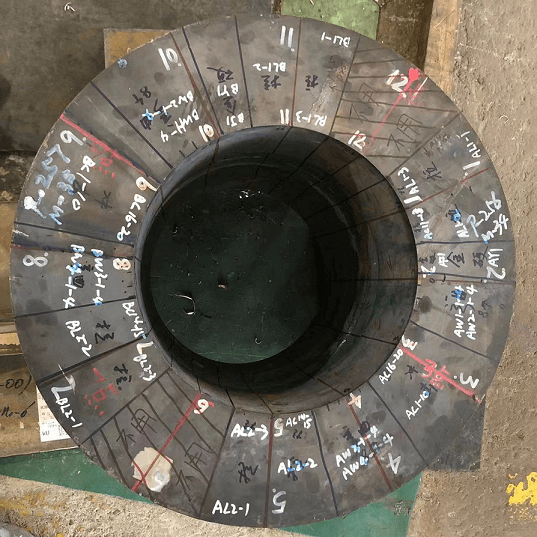

Figure 1 is a preliminary photo of the pipe fittings for this evaluation, and the pipe fitting size: φ530×115mm.

Preparation of pipe fittings before welding

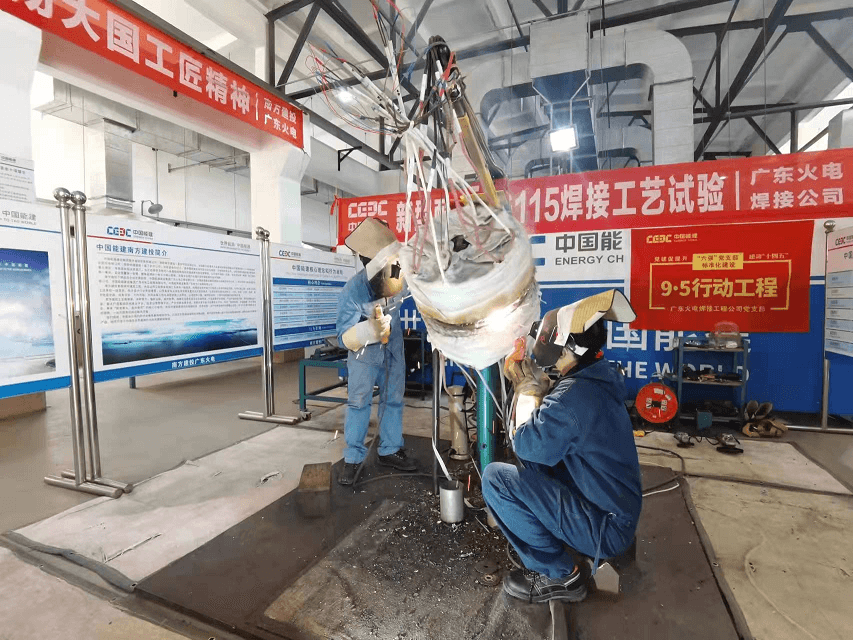

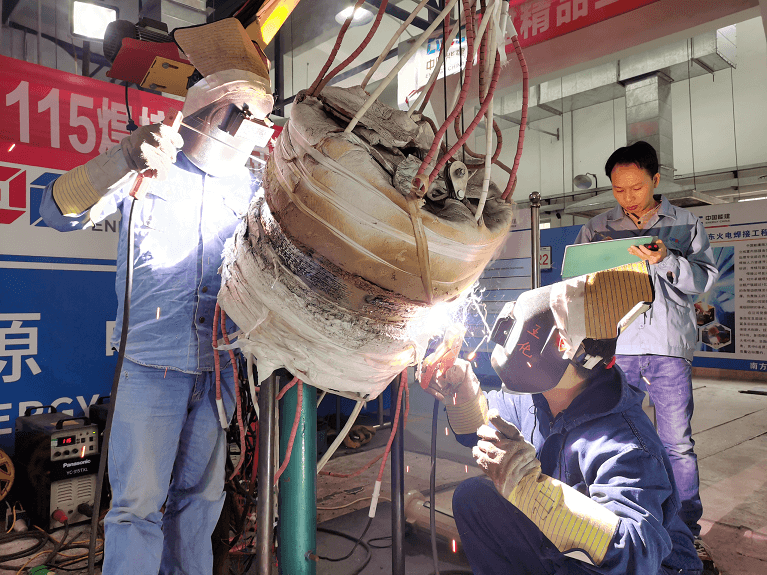

Figures 2 and 3 are photo examples of the welding process, the welding position is 6G, and the process parameters are strictly recorded and controlled by its process personnel.

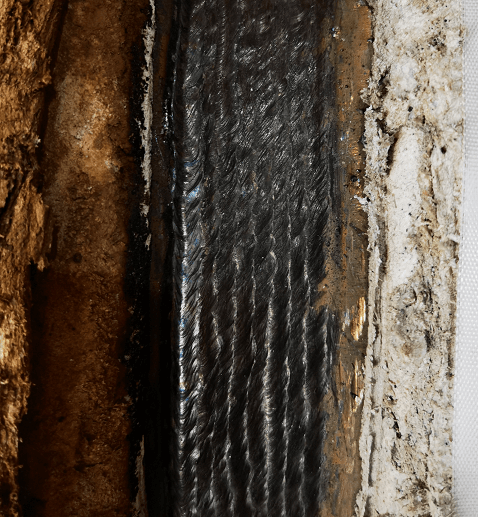

Fig. 4 and Figure 5 show the weld after welding, it can be seen that the weld bead is flat, the molten pool is suitable, and the corrugation is fine, showing that the welding consumables have good all-position welding operation performance.

Figure 6 shows the remaining length of our electrode after welding, it can be seen that the residual after welding is basically less, showing the good fire resistance of the electrode, in the high heat state of welding can always maintain the arc and molten pool state, the utilization rate of a single electrode is high, to avoid waste.

The subsequent heat treatment temperature is 775 °C, constant temperature for 12 hours, Figure 7 is a schematic photo of each test sample.

The test results of each sample of the pipe welding assessment have been released, the tensile performance is excellent, and the tensile plates are broken in the position of the base metal; The impact absorption work is good and there is a certain margin; The hardness value is in line; The bent pieces taken are free of cracks and other defects. The overall results are satisfactory and meet the expected requirements of the assessment.

If you need more information, please feel free to call us!

We will continue to work on the localization process of high-end welding consumables. To contribute to the national energy strategy, energy conservation and emission reduction, I hope to have the opportunity to learn from more like-minded enterprises and friends, and work together!

Post time: Dec-01-2022