Whatsapp:+8613252436578 E-mail:sale@welding-honest.com

1. classification

According to the amount of carbon content, carbon steel can be divided into the following three categories:

1) Low carbon steel C% ≤ 0.25

2) Medium carbon steel 0.25<C%≤0.6

3) High carbon steel C% > 0.6

Low Carton

Mid-Carbon

High-Carbon

2. weldability analysis

The amount of carbon content is an important reference for the development of welding processes. As the carbon content increases, the strength and hardness increase, while the plasticity and toughness decrease, while the stress increases. Relatively speaking, the lower the carbon content, the better the weldability, therefore, the carbon content is the standard for judging the difficulty of carbon steel welding, and different welding processes should be adopted for different carbon content.

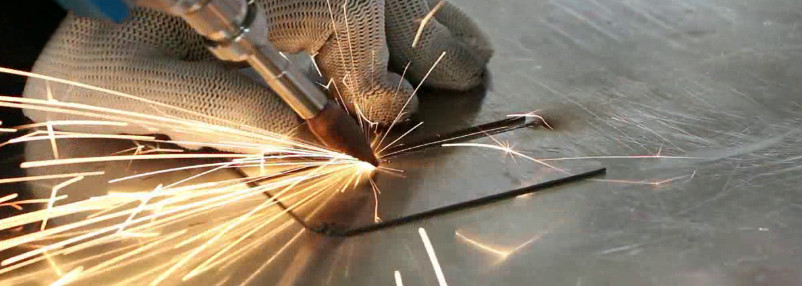

3. Welding process

The selection of carbon steel welding materials follows the principle of "equal strength"

1. Low carbon steel (commonly known as mild steel)

Common steel grades such as Q235 (early commonly known as A3 steel), Q255, etc., generally do not take special measures when welding, neither preheating nor postheating.

2. Medium carbon steel

Commonly used steel such as 30#, 45#, etc., 45# is the material for manufacturing saw blades and files, it is best to use low-hydrogen welding materials with good crack resistance, preheating 100-200 °C; If it is not convenient to preheat, Cr-Ni austenitic stainless steel welding material can be selected.

3. High carbon steel

Commonly used steel grades such as 60Si2Mn, T8, T10 and so on. 60Si2Mn is a typical spring steel, generally do not carry out welding treatment, mostly used as re-welding, should be 250-350 °C preheating, welding must be hammered to eliminate stress, and 650 °C post-heat treatment, can also choose Cr-Ni austenitic stainless steel welding materials

Fourth, mild steel hand electrode general welding essentials:

Electrode drying temperature

|

Item |

Skin type |

Product |

Temperature |

Time |

|

Low carbon steel and high strength steel |

Low hydrogen type |

E7016、E7048、E7015、E7015-G |

300-350℃ |

60min |

|

E7015、E8015-G、E9016-G、E9015-D1、E10015-D2、E12015-G |

330-380℃ |

|||

| High toughness and low hydrogen type |

E7016-G、E7015-G、E8015-G、E9015-G、E10015-G |

350-380℃ |

60min |

|

| Iron powder low hydrogen type |

E7018、E7018-1 |

300-350℃ |

60min |

|

|

E8018-G、E918-G、E9018-M、E10018-D2、E10018M、E11018-G、E11018M、E12018-G |

350-380℃ |

60min |

2. The moisture, oil, rust, etc. on the surface of the base material should be removed

3. Use the backward forward method to weld to avoid stomata at the starting point

Short arc welding should be used, such as oscillating strips, and the oscillation amplitude should not exceed 3 times the wire diameter.

Post time: Oct-13-2022