Web:www.welding-honest.com Whatsapp:+86 13252436578

In the process of crude oil storage and transportation, due to the high sulfur content in crude oil, ordinary steel is exposed to wet H2S environment for a long time, which is prone to hydrogen-induced cracks and hydrogen sulfide stress corrosion cracking, burying a major safety hazard for safe production.

In response to the above problems, hydrogen-resistant steel has been widely used in major domestic petrochemical, thermal power, desulfurization tower and other projects due to its good resistance to hydrogen-induced cracking and sulfide stress corrosion cracking. Common grades are 16MnR (HIC), Q345/Q355 (HIC), API 5L X52, ASTM A516 Gr.70 (HIC).

At present, Chinese steel mills have completed independent production of hydrogen-resistant steel, successfully replacing imported products. With the gradual development of large-scale petrochemical equipment, in order to improve production efficiency, the market urgently needs a high-efficiency welding material for production welding. Our company has launched a submerged arc welding wire and flux that match the base metal with excellent resistance to hydrogen-induced cracking and sulfide stress corrosion cracking.

The physical and chemical properties of the hydrogen-resistant steel submerged arc welding wire GWL-W10KHMSHA with flux GXL-121 developed by our company are as follows:

product introduction

|

Category |

Product name |

Standards compliant |

|

Welding wire |

GWL-W10KHMSHA |

AWS A5.17 EH10K GB/T 5293 SU10 |

|

Flux |

GB/T 36037 S A FB1 ISO 14174 SA FB1 |

|

|

Features |

||

| 1.Submerged arc welding wire and flux for 490Mpa class hydrogen-resistant steel;

2. The wire composition is pure, and the P.S impurity content is low 3. Fluorine-alkali flux, low impurity, suitable pH, taking into account manufacturability and mechanical properties 4.HIC SSC test can meet the requirements |

||

Chemical Composition of Welding Wire

|

Category/Nmae |

GWL-W10KHMSHA |

|

|

Chemical Composition(wt %) |

C |

0.045 |

|

Mn |

1.05 |

|

|

Si |

0.40 |

|

|

P |

0.008 |

|

|

S |

0.003 |

|

|

Cu |

0.008 |

|

|

Mo |

0.20 |

|

Typical values of mechanical properties of deposited metal

|

Category/Nmae |

GWL-W10KHMSHA GXL-121 |

|

|

Sample status |

AW |

620℃*12h |

|

Yield Strength(Mpa) |

455 |

425 |

|

tensile strength(Mpa) |

535 |

510 |

|

Elongation(%) |

30.0 |

29.5 |

|

-20℃ impact KV2(J) |

280 |

290 |

|

HB |

180 |

170 |

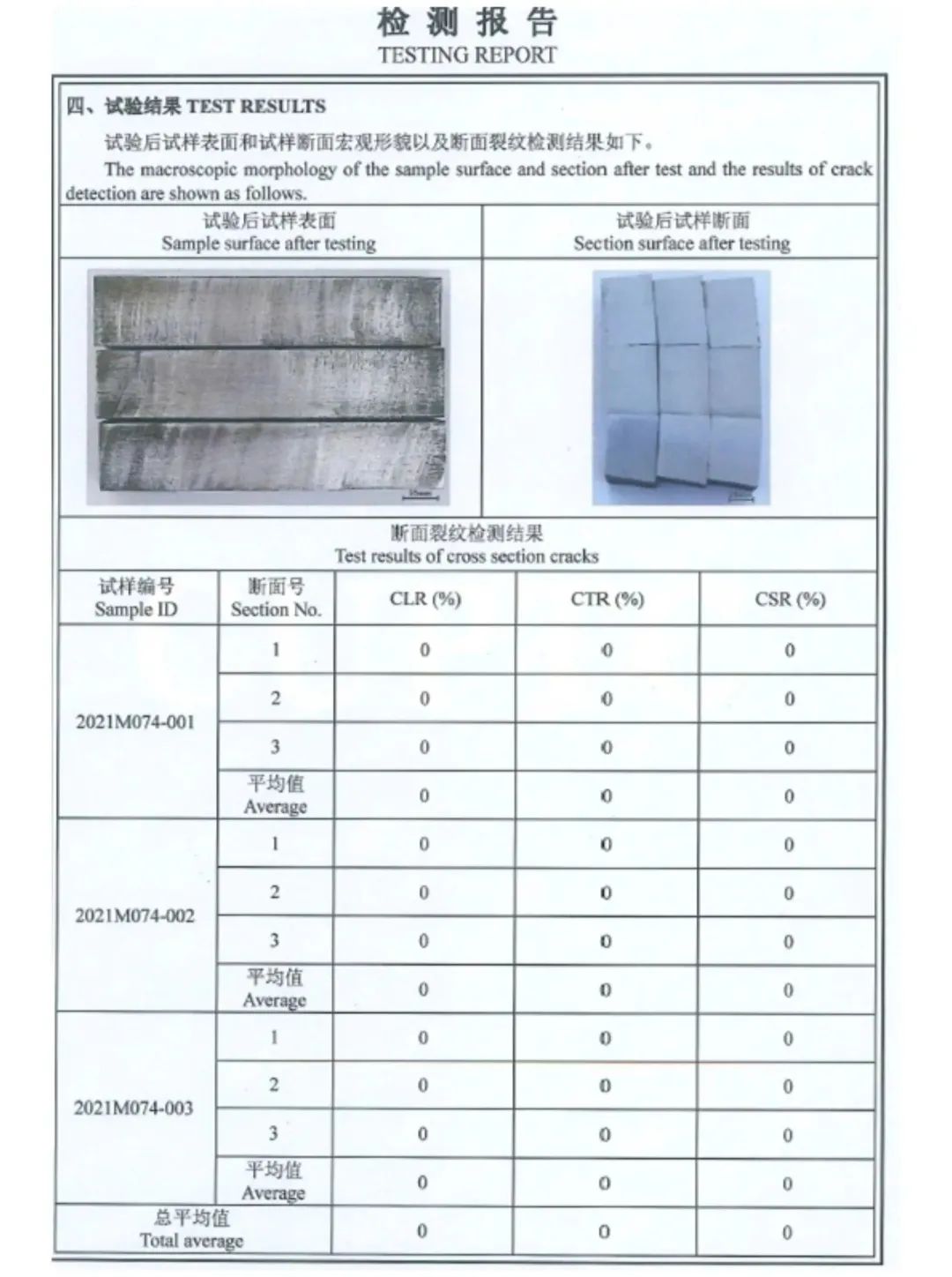

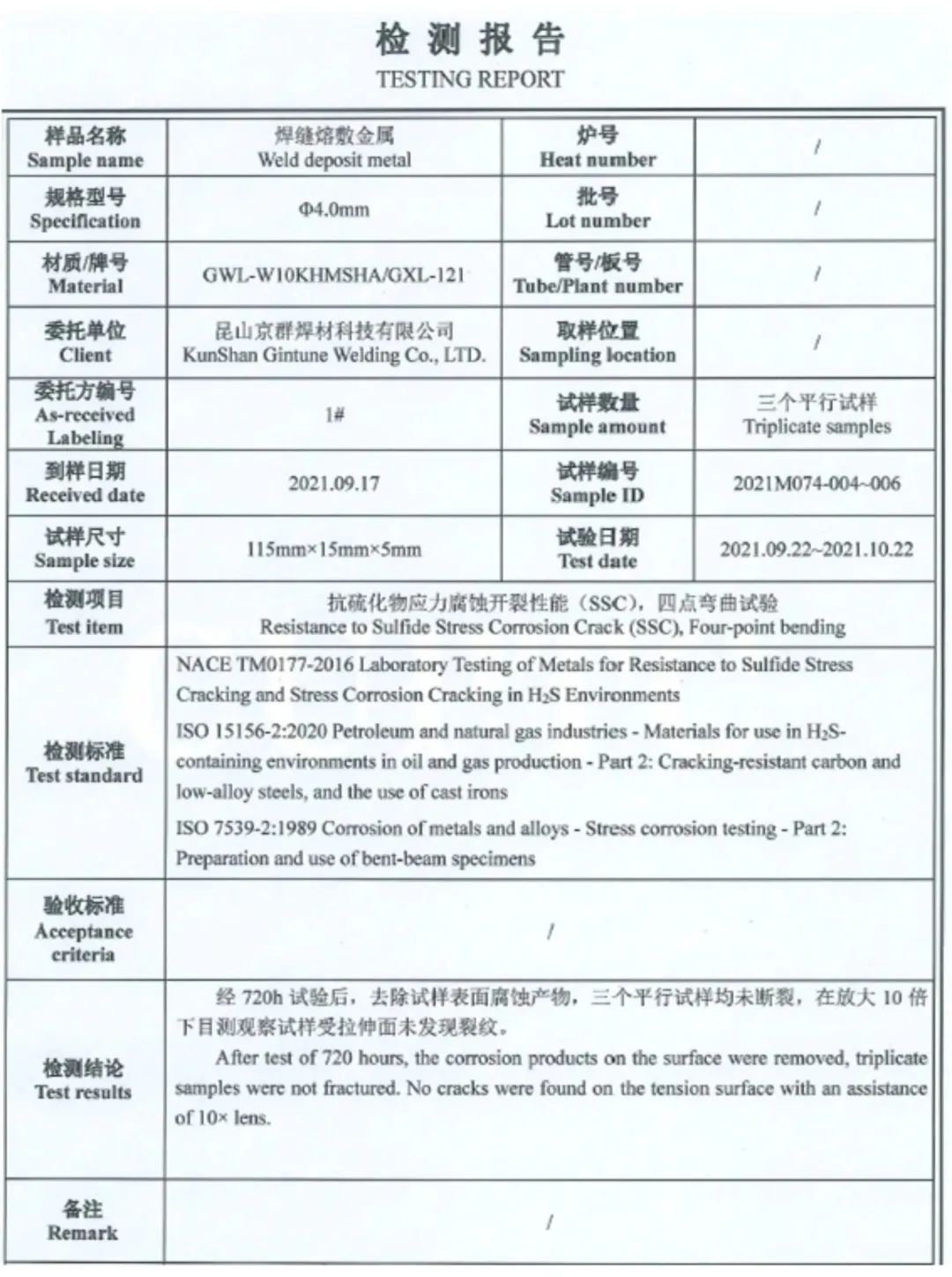

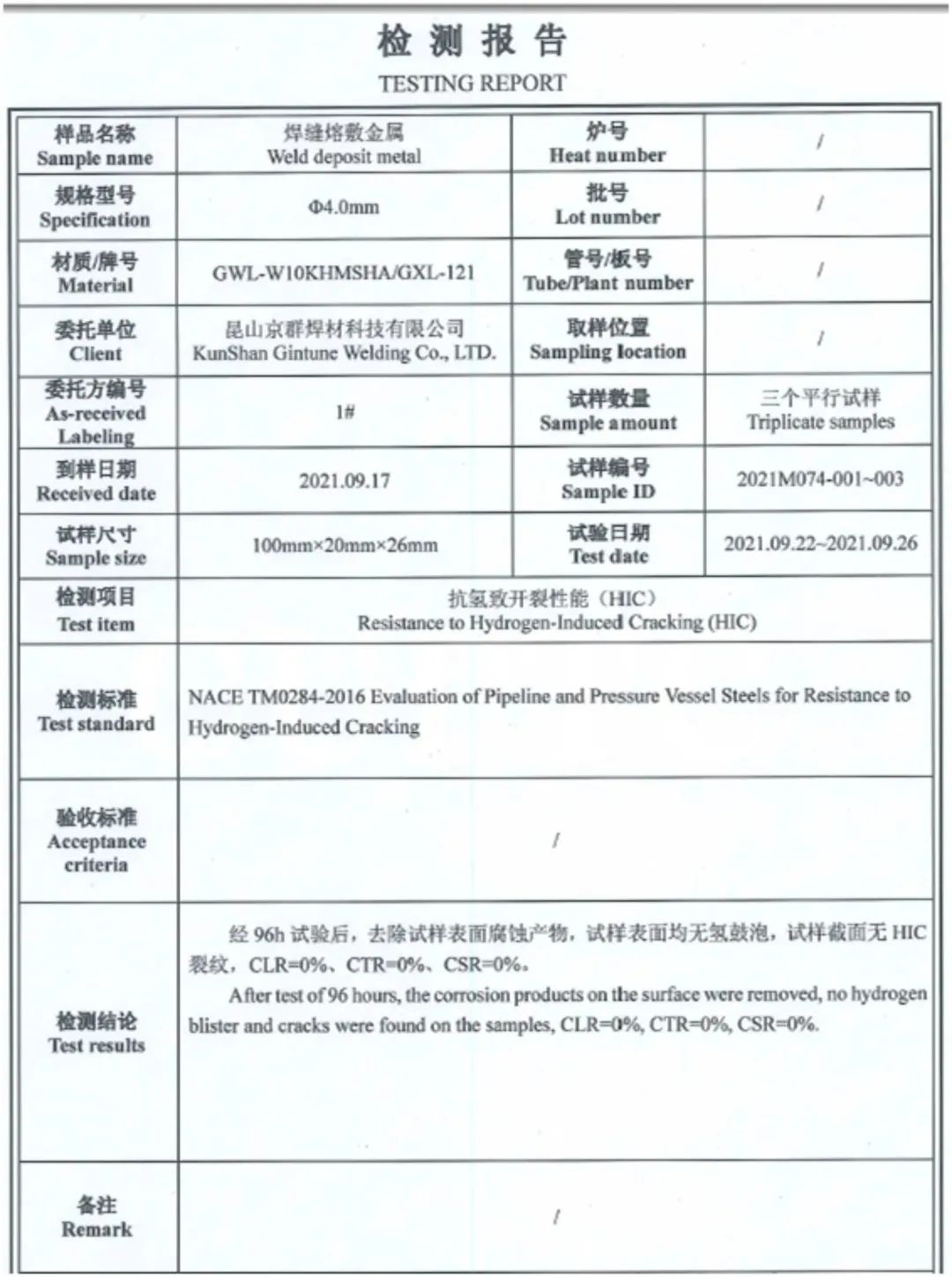

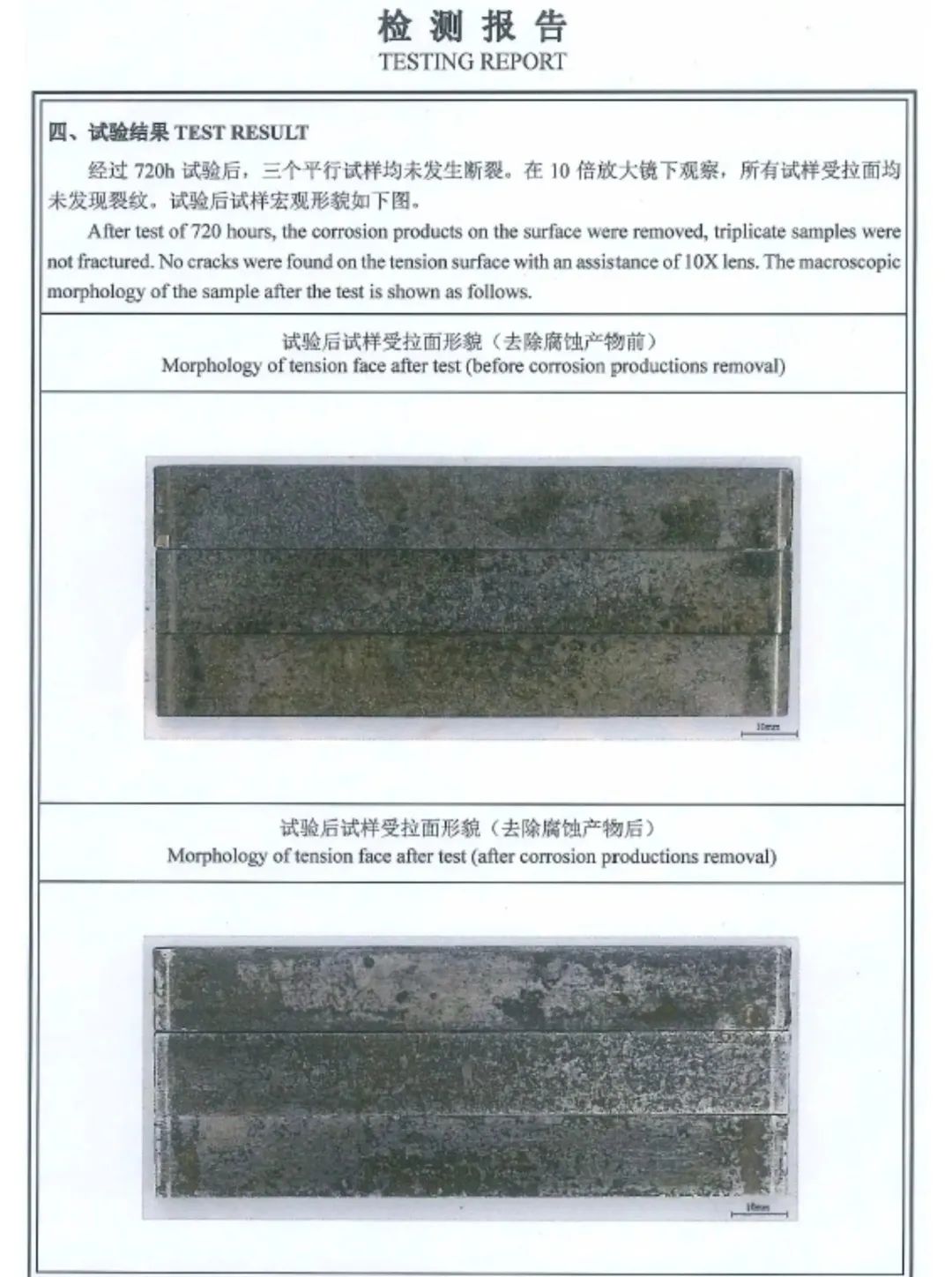

The hydrogen-resistant steel submerged arc welding wire GWL-W10KHMSHA combined with flux GXL-121 developed by our company has excellent welding workability. The performance of HIC and SSC has passed the third-party inspection. The welding pictures and inspection reports are shown in the figure below:

Scrubber

Picture of welding operation in groove

Ningbo Honest Metal Materials Co., Ltd. Hydrogen-resistant steel welding consumables include metal powder cored wire, hand electrode, and solid wire, with a complete range and excellent performance, which can be used in different welding methods and under various working conditions. Welcome to buy.

More information send to E-mail: export@welding-honest.com

Post time: Feb-14-2023