Nickel alloys TIG ERNiCrFe-7A Soldering jointing

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | Fe | Nb+Ta | P | S |

| GB/T RULES | - | - | - | - | - | - | - | - | - | - |

| AWS RULES | 0.04 | 1.00 | 0.50 | 28.0-31.5 | Rem | 0.50 | 7.0-11.0 | 0.5-1.0 | 0.02 | 0.015 |

| EXAMPLE VALUE | 0.028 | 0.15 | 0.11 | 29.8 | 59.03 | 0.06 | 9.8 | 0.86 | 0.001 | 0.002 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | Heat treatment | ||||||

| GB/T RULES | - | - | - | - | - | ||||||

| AWS RULES | - | - | - | - | - | ||||||

| EXAMPLE VALUE | - | 760 | 133/Room temperature | 37 | 607°C*25h | ||||||

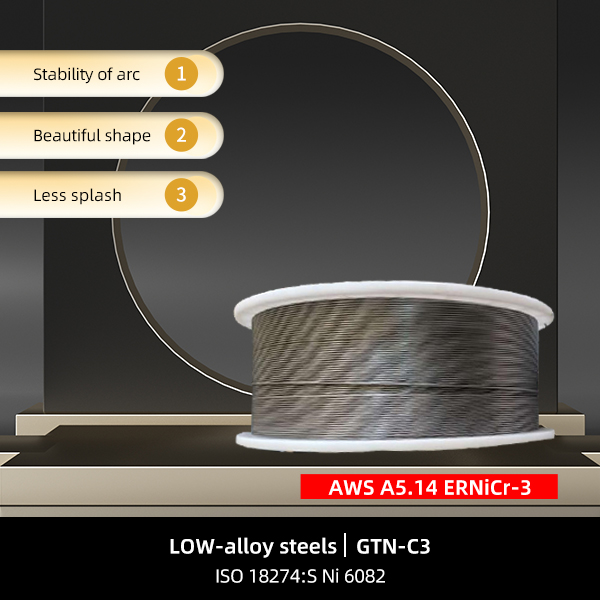

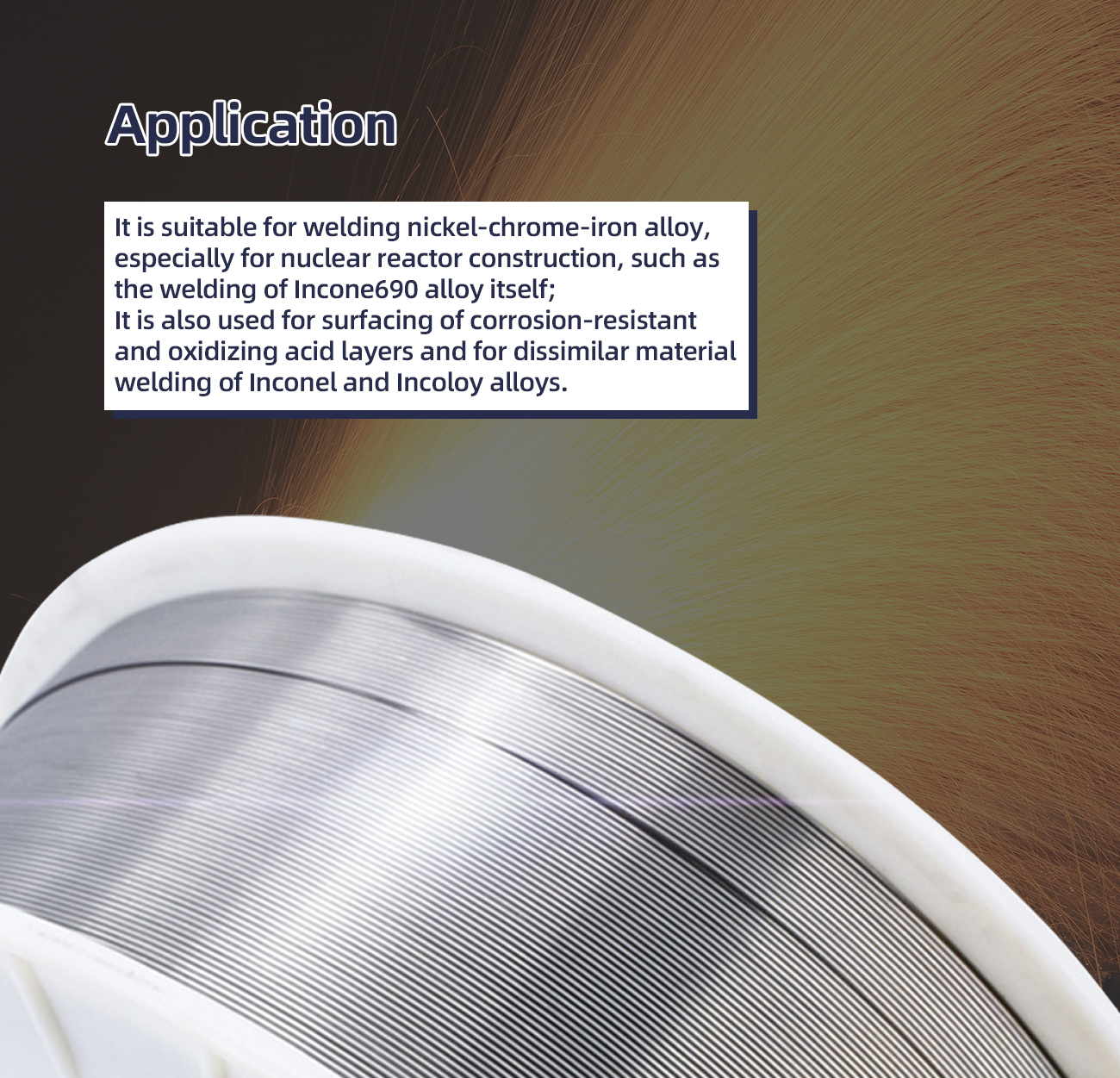

Nickel-chromium-iron nickel-base alloy gas welding wire, nominal composition is 60%Ni-29%Cr-9%Fe-0.75%Nb.

Good mechanical properties of molten metal, especially resistance to low plastic cracking (DDC).

High Cr content makes it have excellent stress corrosion cracking resistance in pure water environment under radiation condition. Stable arc, beautiful forming, good flow of molten iron, with excellent welding process performance.

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | Fe | Nb+Ta | P | S |

| GB/T RULES | - | - | - | - | - | - | - | - | - | - |

| AWS RULES | 0.04 | 1.00 | 0.50 | 28.0-31.5 | Rem | 0.50 | 7.0-11.0 | 0.5-1.0 | 0.02 | 0.015 |

| EXAMPLE VALUE | 0.028 | 0.15 | 0.11 | 29.8 | 59.03 | 0.06 | 9.8 | 0.86 | 0.001 | 0.002 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | Heat treatment | ||||||

| GB/T RULES | - | - | - | - | - | ||||||

| AWS RULES | - | - | - | - | - | ||||||

| EXAMPLE VALUE | - | 760 | 133/Room temperature | 37 | 607°C*25h | ||||||

Write your message here and send it to us