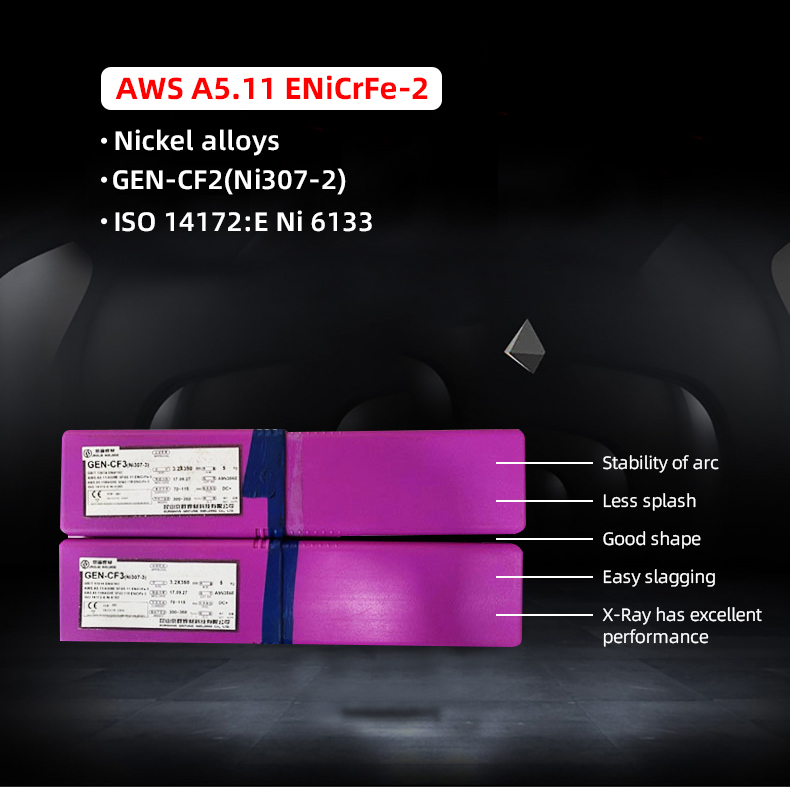

Nickel alloys Manual electrode ENiCrFe-2 Welding stuff

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Fe | Nb+Ta | P | S | Mo | ||

| GB/T RULES | 0.10 | 1.0-3.5 | 0.80 | 13.0-17.0 | ≥62 | 12.00 | 0.5-3.0 | 0.02 | 0.015 | 0.5-3.0 | ||

| AWS RULES | 0.10 | 1.0-3.5 | 0.75 | 13.0-17.0 | ≥62 | 12.00 | 0.5-3.0 | 0.03 | 0.02 | 0.5-2.5 | ||

| EXAMPLE VALUE | 0.036 | 3.19 | 0.48 | 14.6 | 70.8 | 7.04 | 1.67 | 0.009 | 0.003 | 1.63 | ||

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 360 | 550 | - | 27 | ||||

| AWS RULES | - | 550 | - | 30 | ||||

| EXAMPLE VALUE | 430 | 660 | - | 44 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*300 | 3.2*350 | 4.0*350 | ||||||||

| ELECTRICITY (Amp) |

H/W | 69-95 | 70-115 | 95-145 | |||||||

| O/W | 55-80 | 65-110 | 80-130 | ||||||||

Low hydrogen type hand electrode, nominal composition (weight percent) is 7ONi-15Cr-8Fe-2Mn-2Nb+Ta-1.5Mo, for nickel-chrome-iron alloy electrode.

The base metal can be forged or cast (weldable grade) and can be adapted to temperatures ranging from low temperatures to 980 ° C; However, when the temperature is higher than 820℃, the oxidation resistance and strength will deteriorate.

Stable arc, beautiful forming, little splash, easy slag removal, good porosity resistance, the mechanical properties of the molten metal is stable, and has excellent low temperature impact and high temperature oxidation resistance.

-

10000TEU container ship

-

Thermal power application

Zhangjiagang CIMC Sundayin Cryogenic Equipment Co., LTD. Cryogenic Container (LNG Filling station)

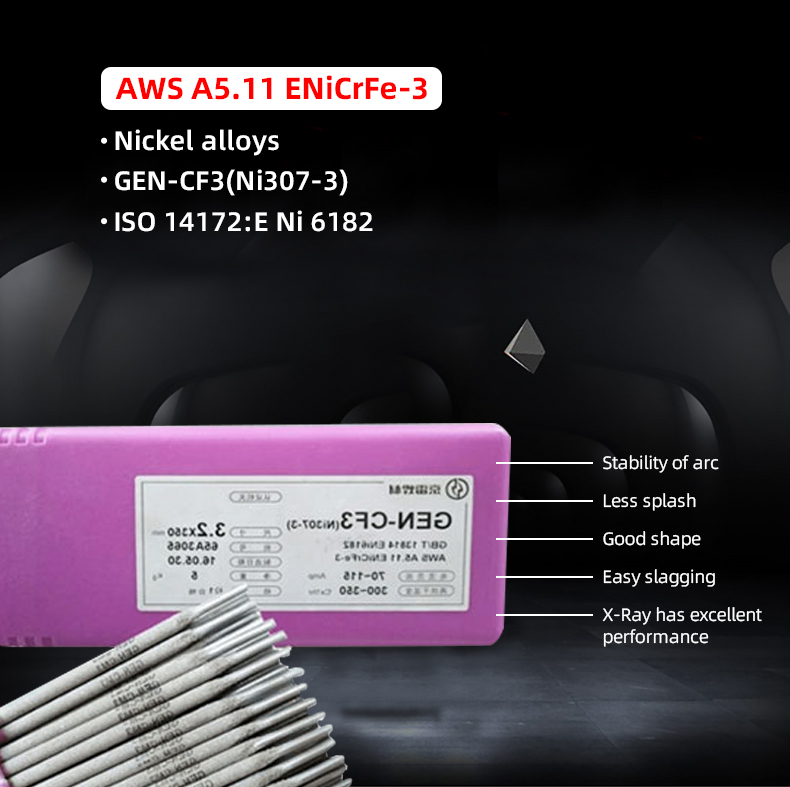

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Fe | Nb+Ta | P | S | Mo | ||

| GB/T RULES | 0.10 | 1.0-3.5 | 0.80 | 13.0-17.0 | ≥62 | 12.00 | 0.5-3.0 | 0.02 | 0.015 | 0.5-3.0 | ||

| AWS RULES | 0.10 | 1.0-3.5 | 0.75 | 13.0-17.0 | ≥62 | 12.00 | 0.5-3.0 | 0.03 | 0.02 | 0.5-2.5 | ||

| EXAMPLE VALUE | 0.036 | 3.19 | 0.48 | 14.6 | 70.8 | 7.04 | 1.67 | 0.009 | 0.003 | 1.63 | ||

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 360 | 550 | - | 27 | ||||

| AWS RULES | - | 550 | - | 30 | ||||

| EXAMPLE VALUE | 430 | 660 | - | 44 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*300 | 3.2*350 | 4.0*350 | ||||||||

| ELECTRICITY (Amp) |

H/W | 69-95 | 70-115 | 95-145 | |||||||

| O/W | 55-80 | 65-110 | 80-130 | ||||||||