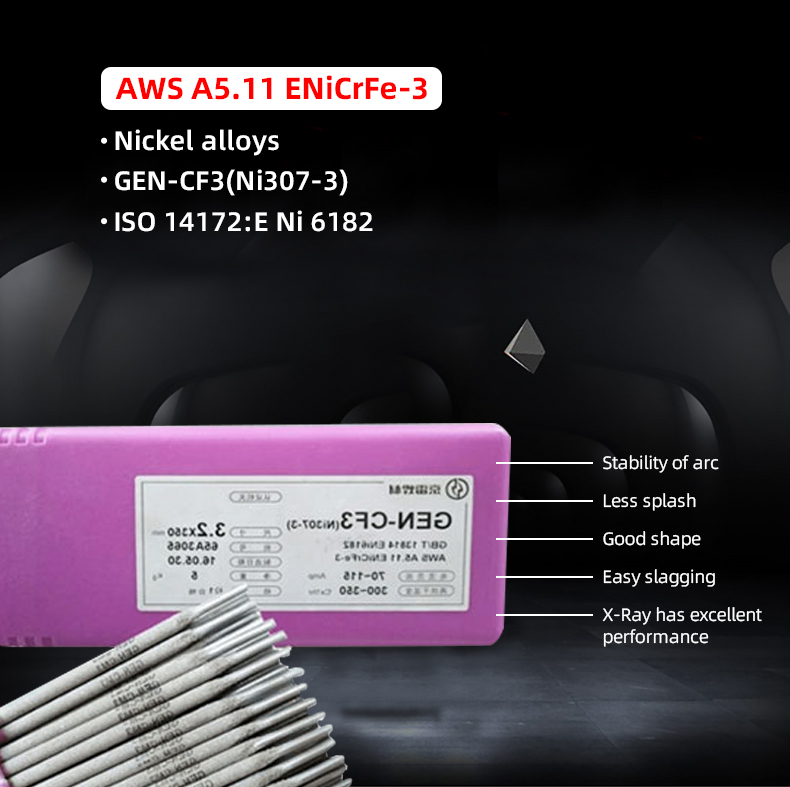

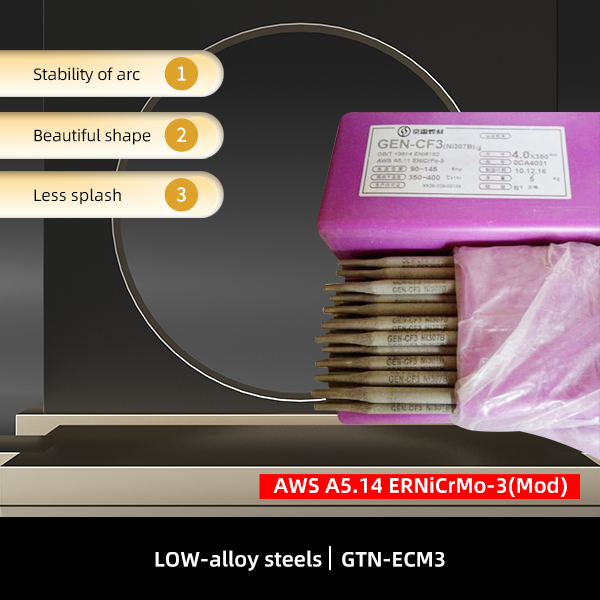

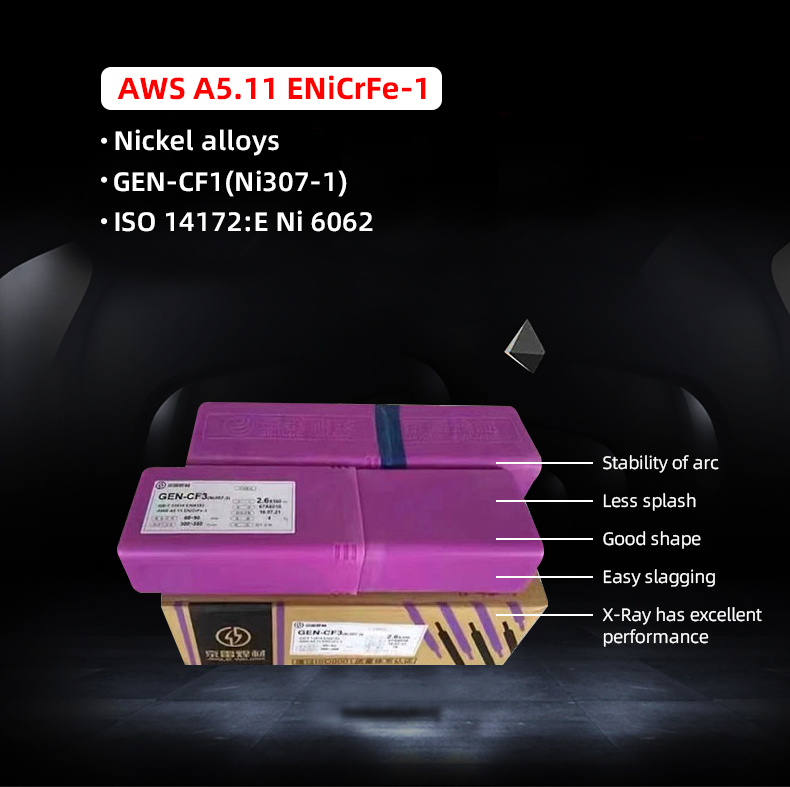

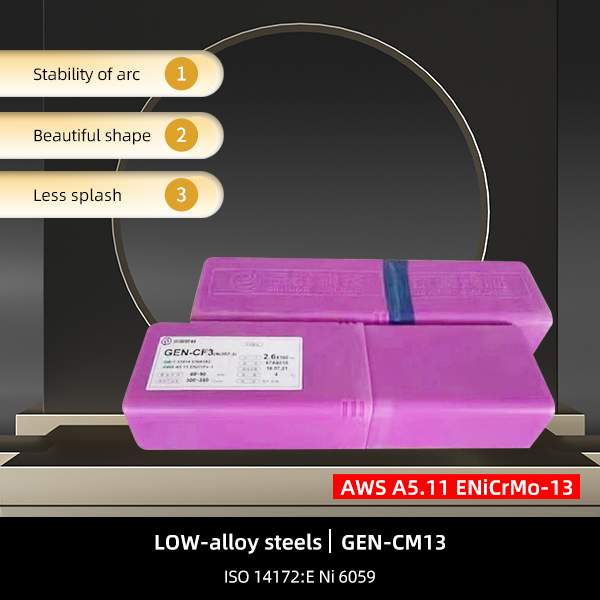

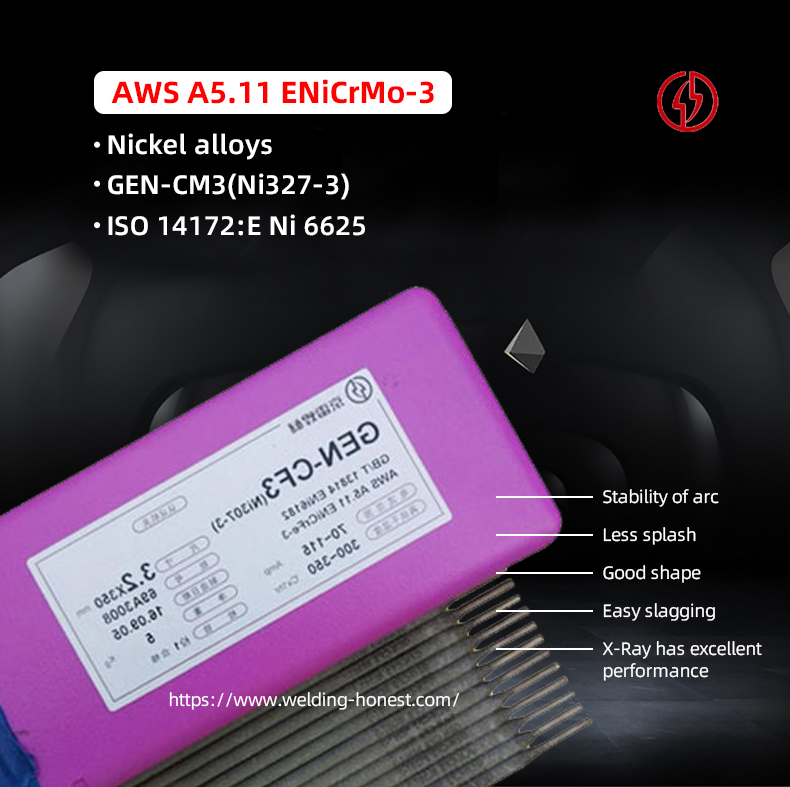

Nickel alloys Manual electrode ENiCrFe-3 Welding jointing

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Fe | Nb+Ta | P | S | |

| GB/T RULES | 0.10 | 5.0-10.0 | 1.00 | 13.0-17.0 | ≥60 | 10.00 | 1.0-3.5 | 0.02 | 0.015 | |

| AWS RULES | 0.10 | 5.0-9.5 | 1.00 | 13.0-17.0 | ≥59 | 10.00 | 1.0-2.5 | 0.03 | 0.015 | |

| EXAMPLE VALUE | 0.046 | 7.6 | 0.45 | 15.7 | 15.7 | 3.56 | 1.76 | 0.005 | 0.004 | |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 360 | 550 | - | 27 | ||||

| AWS RULES | - | 550 | - | 30 | ||||

| EXAMPLE VALUE | 410 | 650 | - | 40 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*300 | 3.2*350 | 4.0*350 | ||||||||

| ELECTRICITY (Amp) |

H/W | 69-95 | 70-115 | 95-145 | |||||||

| O/W | 55-80 | 65-110 | 80-130 | ||||||||

Low hydrogen type hand electrode, nominal composition (weight percent) is 65Ni-15Cr-8Fe-7.5Mn-2Nb+Ta, for nickel-chrome-iron alloy electrode.

Due to the high content of the alloy, it has high high temperature strength and oxidation resistance and can adapt to the temperature range from low temperature to 480℃.

Stable arc, beautiful forming, little splash, easy slag removal, good porosity resistance, the mechanical properties of molten metal is stable.

-

300,000-ton offshore Floating Production and Storage Tanker (FPSO)

Harbin electric three door CMT

-

Zhejiang Satellite Energy 3× 60,000 m³LPG storage tank

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Fe | Nb+Ta | P | S | |

| GB/T RULES | 0.10 | 5.0-10.0 | 1.00 | 13.0-17.0 | ≥60 | 10.00 | 1.0-3.5 | 0.02 | 0.015 | |

| AWS RULES | 0.10 | 5.0-9.5 | 1.00 | 13.0-17.0 | ≥59 | 10.00 | 1.0-2.5 | 0.03 | 0.015 | |

| EXAMPLE VALUE | 0.046 | 7.6 | 0.45 | 15.7 | 15.7 | 3.56 | 1.76 | 0.005 | 0.004 | |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 360 | 550 | - | 27 | ||||

| AWS RULES | - | 550 | - | 30 | ||||

| EXAMPLE VALUE | 410 | 650 | - | 40 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*300 | 3.2*350 | 4.0*350 | ||||||||

| ELECTRICITY (Amp) |

H/W | 69-95 | 70-115 | 95-145 | |||||||

| O/W | 55-80 | 65-110 | 80-130 | ||||||||

Write your message here and send it to us