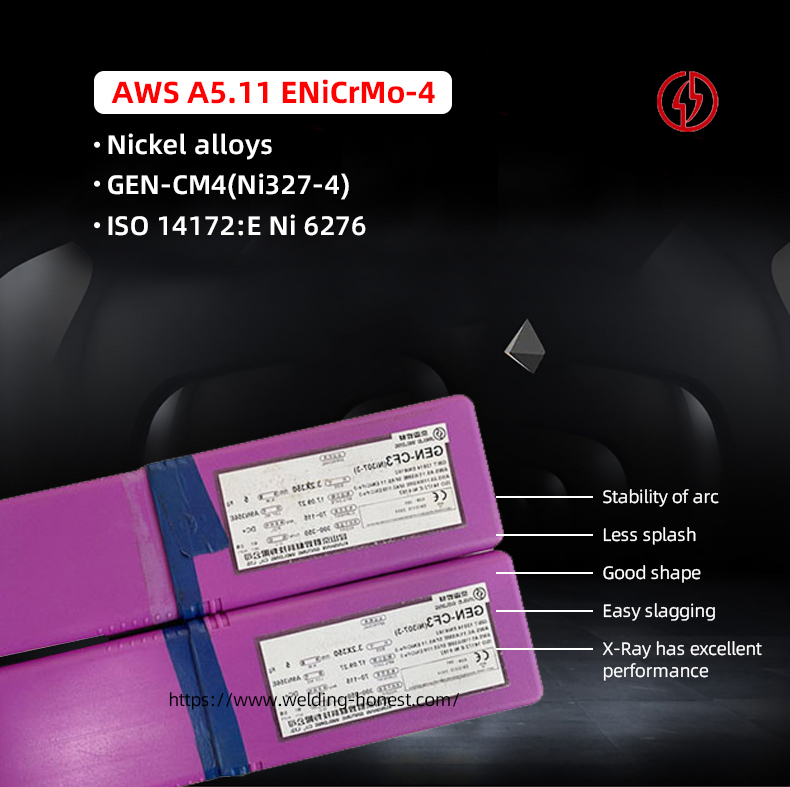

Nickel alloys Manual electrode ENiCrFe-4 Welding data

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Fe | Nb+Ta | P | S | Mo | ||

| GB/T RULES | 0.20 | 1.0-5.0 | 1.00 | 13.0-17.0 | ≥60 | 12.00 | 1.0-3.5 | 0.02 | 0.015 | 1-3.5 | ||

| AWS RULES | 0.20 | 1.0-3.5 | 1.00 | 13.0-17.0 | ≥60 | 12.00 | 1.0-3.5 | 0.03 | 0.02 | 1-3.5 | ||

| EXAMPLE VALUE | 0.09 | 2.8 | 0.37 | 15.35 | 70.75 | 6.05 | 1.82 | 0.070 | 0.005 | 2.43 | ||

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 360 | 650 | - | 18 | ||||

| AWS RULES | - | 650 | - | 20 | ||||

| EXAMPLE VALUE | 464 | 727 | - | 38 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*300 | 3.2*350 | 4.0*350 | ||||||||

| ELECTRICITY (Amp) |

H/W | 69-95 | 70-115 | 95-145 | |||||||

| O/W | 55-80 | 65-110 | 80-130 | ||||||||

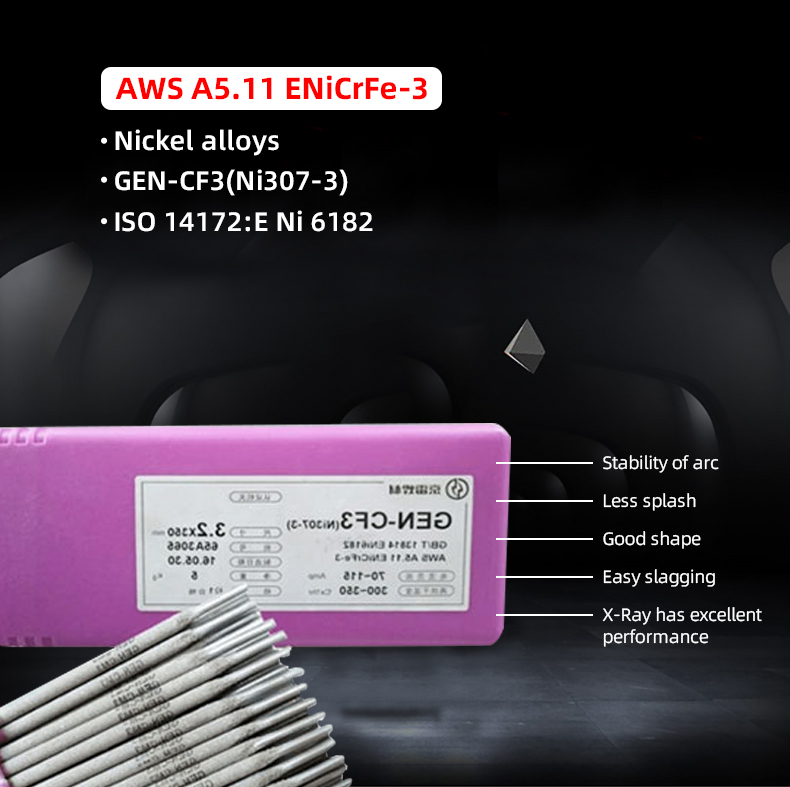

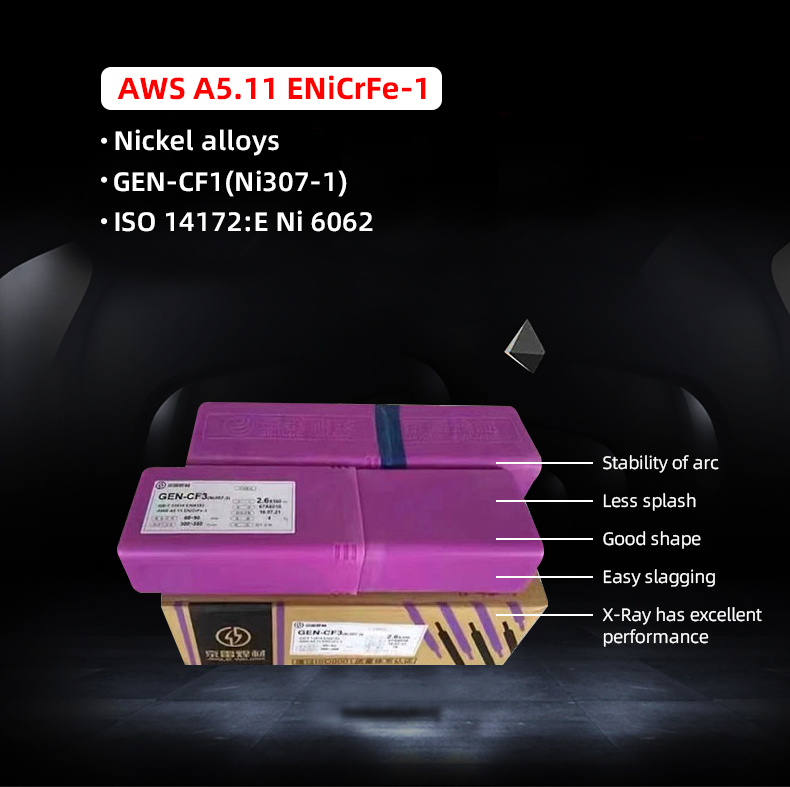

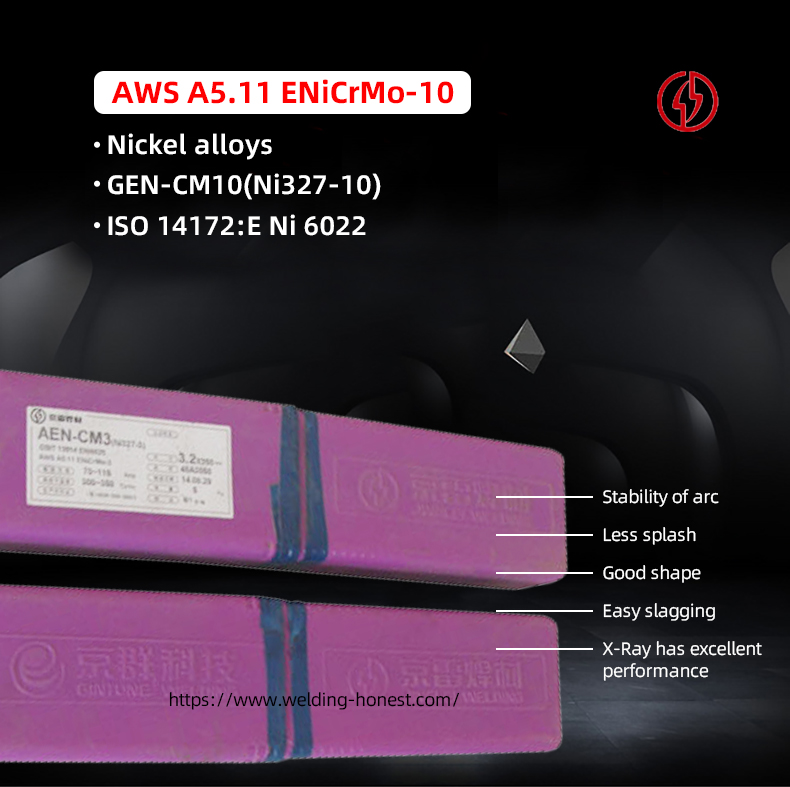

Low H hydrogen type hand electrode, nominal composition (weight white fraction) is 7UNI-15ur-ore-2.OMIl -2. uiWu+Ta-2.5Mo, nickel - chromium - iron alloy electrode.

Stable arc, beautiful forming, little splash, easy slag removal, good porosity resistance.

The mechanical properties of the molten metal is stable, its strength is higher than ENiCrFe-2 category.

-

GDS-2209/GXS-E330 tube surfacing site

-

Welding materials for LNG vehicle bottles

-

Shanghai Morimatsu Storage tank

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Fe | Nb+Ta | P | S | Mo | ||

| GB/T RULES | 0.20 | 1.0-5.0 | 1.00 | 13.0-17.0 | ≥60 | 12.00 | 1.0-3.5 | 0.02 | 0.015 | 1-3.5 | ||

| AWS RULES | 0.20 | 1.0-3.5 | 1.00 | 13.0-17.0 | ≥60 | 12.00 | 1.0-3.5 | 0.03 | 0.02 | 1-3.5 | ||

| EXAMPLE VALUE | 0.09 | 2.8 | 0.37 | 15.35 | 70.75 | 6.05 | 1.82 | 0.070 | 0.005 | 2.43 | ||

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 360 | 650 | - | 18 | ||||

| AWS RULES | - | 650 | - | 20 | ||||

| EXAMPLE VALUE | 464 | 727 | - | 38 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*300 | 3.2*350 | 4.0*350 | ||||||||

| ELECTRICITY (Amp) |

H/W | 69-95 | 70-115 | 95-145 | |||||||

| O/W | 55-80 | 65-110 | 80-130 | ||||||||

Write your message here and send it to us