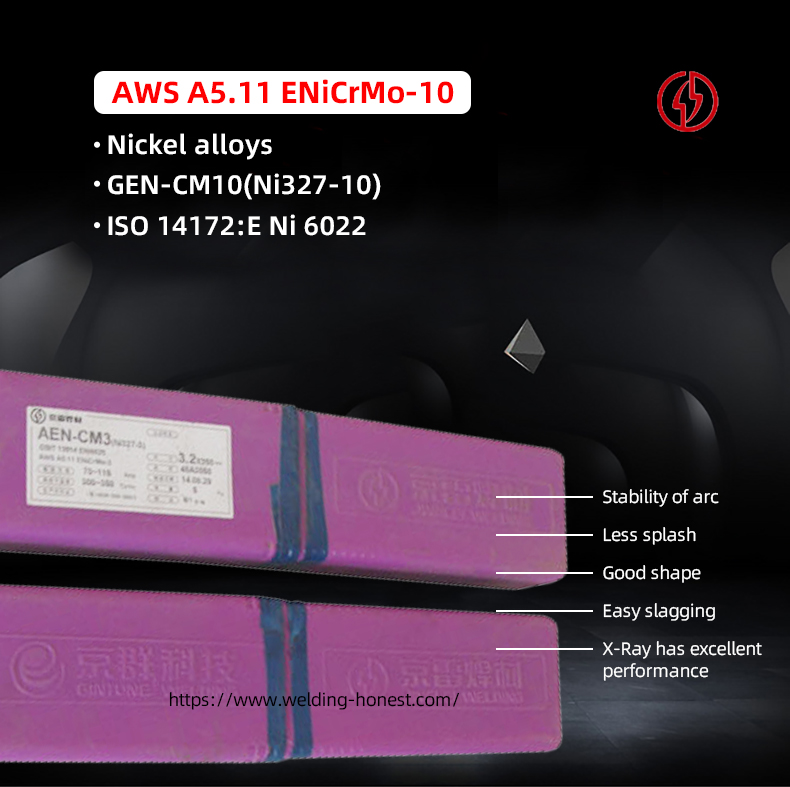

Nickel alloys Manual electrode ENiCrMo-10 weld fabrication data

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Fe | W | Mo | V | Cu | P | S | |

| GB/T RULES | 0.02 | 1.00 | 0.20 | 20.0-22.5 | ≥49 | 2.0-6.0 | 2.5-3.5 | 12.5-14.5 | 0.4 | 0.5 | 0.02 | 0.015 | |

| AWS RULES | 0.02 | 1.00 | 0.20 | 20.0-22.5 | Margin | 2.0-6.0 | 2.5-3.5 | 12.5-14.5 | 0.35 | 0.5 | 0.03 | 0.015 | |

| EXAMPLE VALUE | 0.015 | 0.31 | 0.18 | 21.7 | 55.3 | 4.82 | 3.35 | 13.400 | 0.05 | 0.05 | 0.01 | 0.003 | |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 350 | 690 | - | 22 | ||||

| AWS RULES | - | 690 | - | 25 | ||||

| EXAMPLE VALUE | 530 | 749 | - | 40 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*300 | 3.2*350 | 4.0*350 | ||||||

| ELECTRICITY (Amp) |

H/W | 65-95 | 70-115 | 95-145 | |||||

| O/W | 55-80 | 65-110 | 80-130 | ||||||

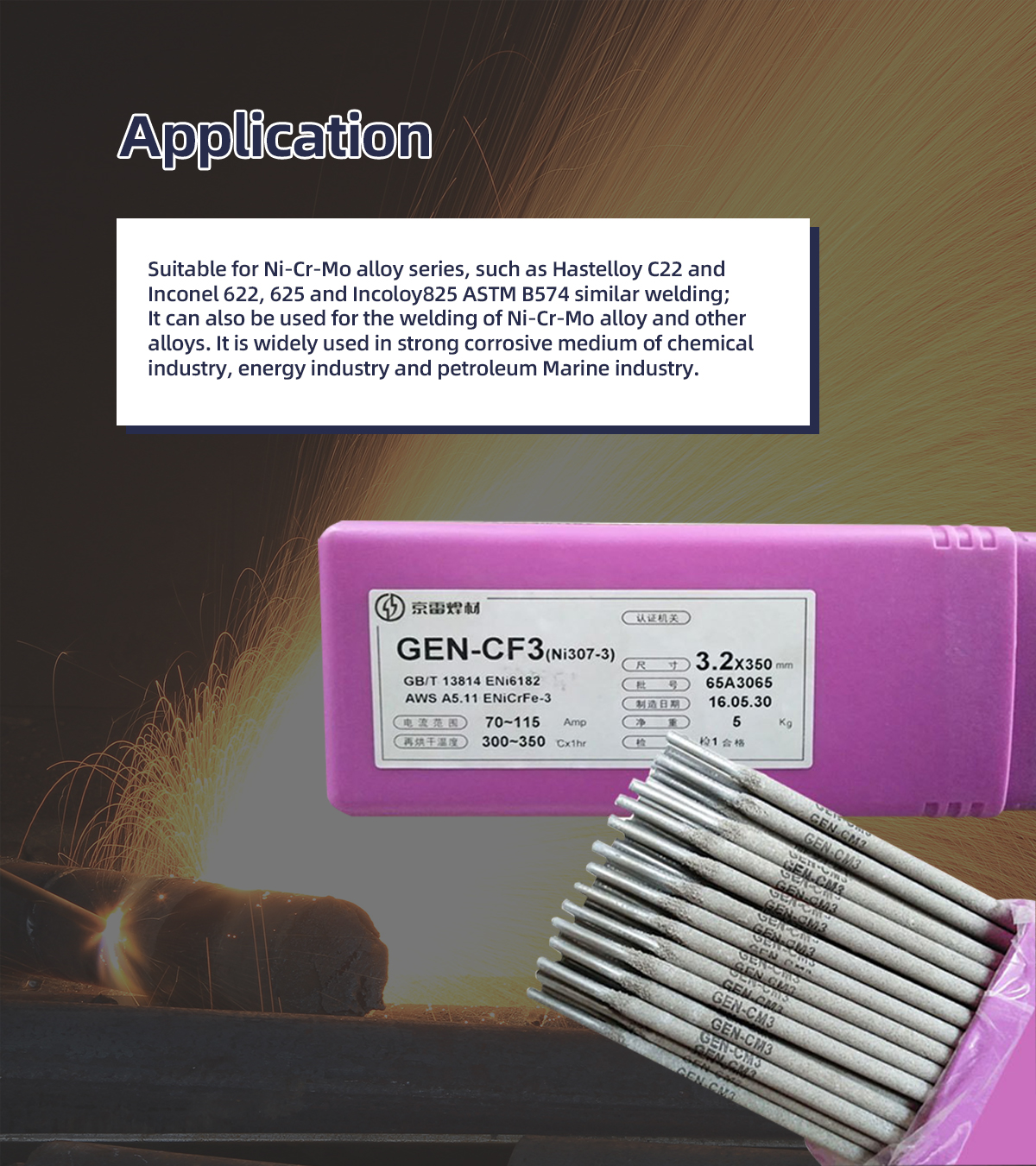

Low hydrogen type hand electrode, nominal composition (weight percent) is 56Ni-22Cr-13Mo-4F-e-3w, nickel-chrome-molybdenum alloy electrode.

Stable arc, beautiful forming, little splash, easy slag removal, good porosity resistance.

The mechanical properties of molten metal is stable.

-

YAMAL LNG project

-

Shandong Nuclear power CV20

-

Hengli Petrochemical 20 million tons/year refining and chemical integration project

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Fe | W | Mo | V | Cu | P | S | |

| GB/T RULES | 0.02 | 1.00 | 0.20 | 20.0-22.5 | ≥49 | 2.0-6.0 | 2.5-3.5 | 12.5-14.5 | 0.4 | 0.5 | 0.02 | 0.015 | |

| AWS RULES | 0.02 | 1.00 | 0.20 | 20.0-22.5 | Margin | 2.0-6.0 | 2.5-3.5 | 12.5-14.5 | 0.35 | 0.5 | 0.03 | 0.015 | |

| EXAMPLE VALUE | 0.015 | 0.31 | 0.18 | 21.7 | 55.3 | 4.82 | 3.35 | 13.400 | 0.05 | 0.05 | 0.01 | 0.003 | |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 350 | 690 | - | 22 | ||||

| AWS RULES | - | 690 | - | 25 | ||||

| EXAMPLE VALUE | 530 | 749 | - | 40 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*300 | 3.2*350 | 4.0*350 | ||||||

| ELECTRICITY (Amp) |

H/W | 65-95 | 70-115 | 95-145 | |||||

| O/W | 55-80 | 65-110 | 80-130 | ||||||

Write your message here and send it to us