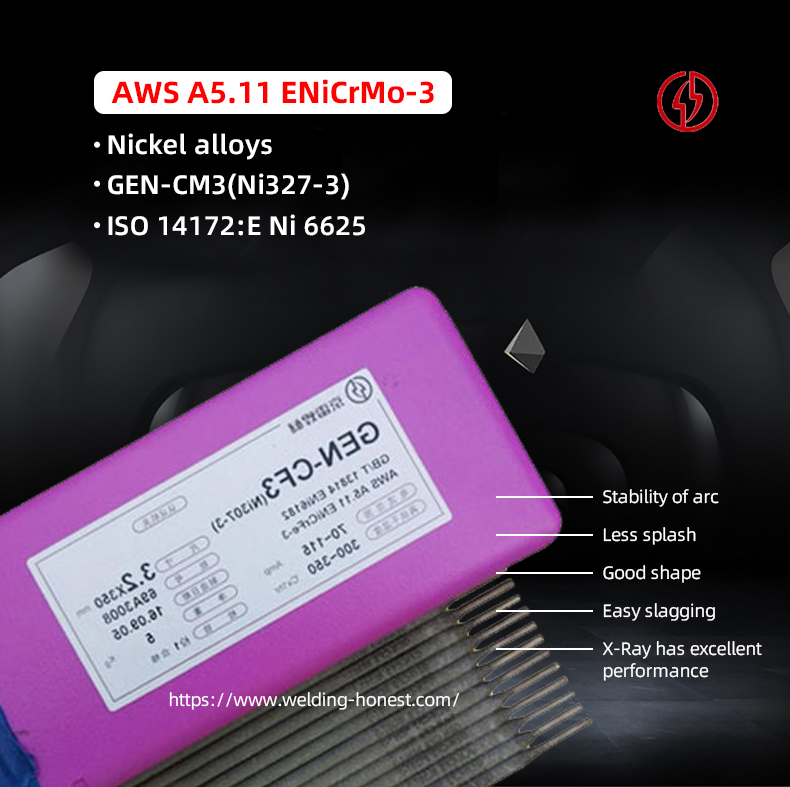

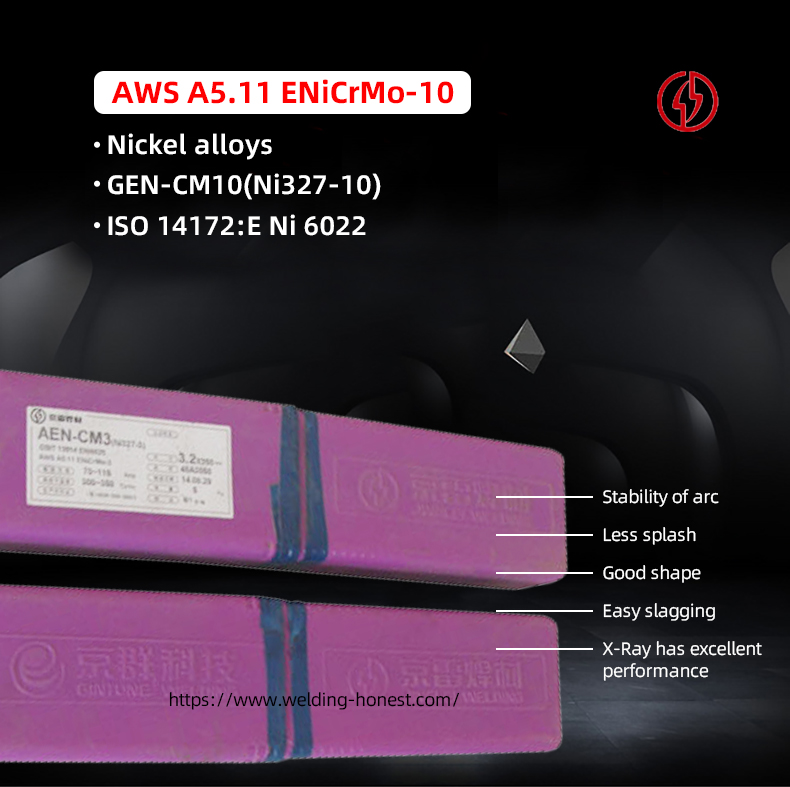

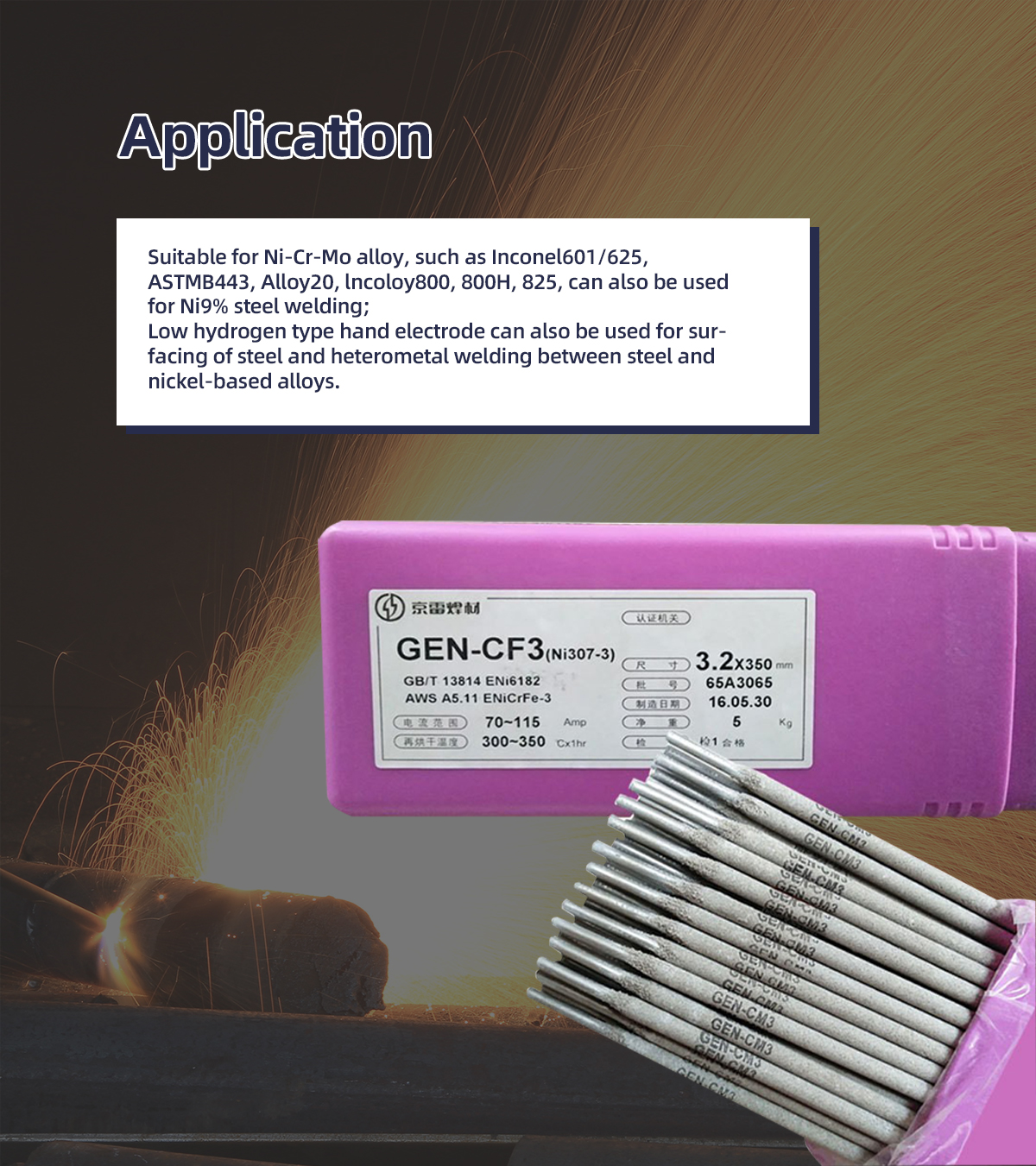

Nickel alloys Manual electrode ENiCrMo-3 weld fabrication accessories

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Fe | Nb+Ta | Mo | P | S | ||

| GB/T RULES | 0.10 | 2.00 | 0.80 | 20.0-23.0 | ≥55 | 7.00 | 3.0-4.2 | 8.0-10.0 | 0.02 | 0.02 | ||

| AWS RULES | 0.10 | 1.00 | 0.75 | 20.0-23.0 | ≥55 | 7.00 | 3.15-4.15 | 8.0-10.0 | 0.03 | 0.02 | ||

| EXAMPLE VALUE | 0.052 | 0.7 | 0.5 | 21.3 | 62.6 | 2.67 | 3.2 | 9.210 | 0.007 | 0.050 | ||

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 420 | 760 | - | 27 | ||||

| AWS RULES | - | 760 | - | 30 | ||||

| EXAMPLE VALUE | 545 | 790 | - | 40.5 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*300 | 3.2*350 | 4.0*350 | ||||||||

| ELECTRICITY (Amp) |

H/W | 69-95 | 70-115 | 95-145 | |||||||

| O/W | 60-80 | 65-105 | 80-135 | ||||||||

Nominal composition (percent by weight) is 60Ni-22Cr-9Mo-Fe-3.5Nb+Ta, a nickel-chrome-molybdenum alloy electrode.

Due to the high content of alloy, it can adapt to the temperature range from low temperature to 540℃.

It has high strength and corrosion resistance at room temperature and high temperature, including pitting corrosion resistance, crack corrosion and stress corrosion in polysulfurous acidic media.

Stable arc, beautiful forming, little splash, easy slag removal, good porosity resistance, the mechanical properties of molten metal is stable.

-

Three door 2# is not active

-

3000m deepwater semi-submersible drilling platform "Haiyang Shiyou 981"

-

9,000 tons of chemicals

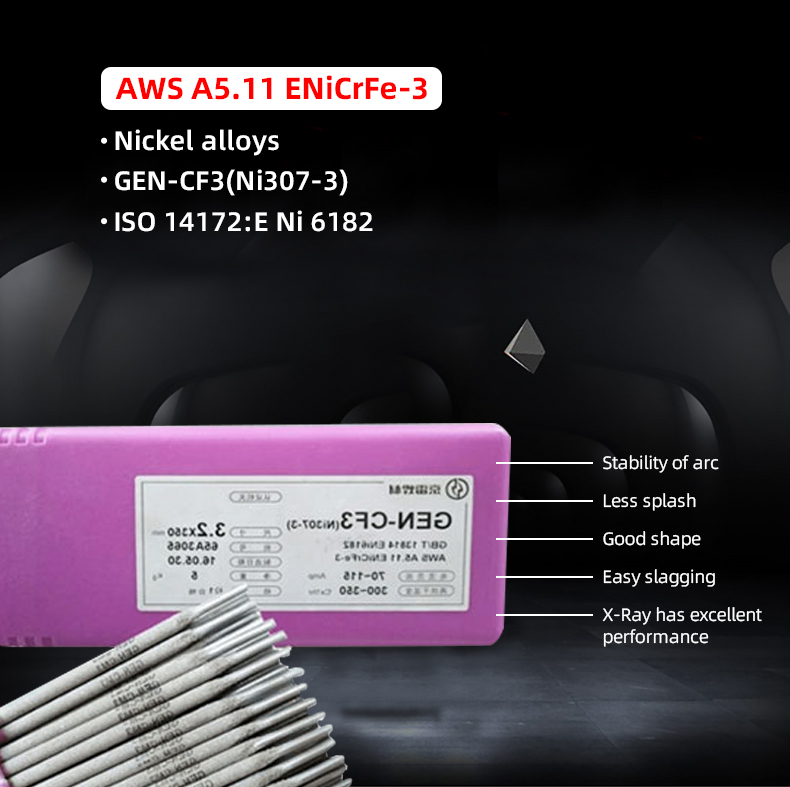

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Fe | Nb+Ta | Mo | P | S | ||

| GB/T RULES | 0.10 | 2.00 | 0.80 | 20.0-23.0 | ≥55 | 7.00 | 3.0-4.2 | 8.0-10.0 | 0.02 | 0.02 | ||

| AWS RULES | 0.10 | 1.00 | 0.75 | 20.0-23.0 | ≥55 | 7.00 | 3.15-4.15 | 8.0-10.0 | 0.03 | 0.02 | ||

| EXAMPLE VALUE | 0.052 | 0.7 | 0.5 | 21.3 | 62.6 | 2.67 | 3.2 | 9.210 | 0.007 | 0.050 | ||

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 420 | 760 | - | 27 | ||||

| AWS RULES | - | 760 | - | 30 | ||||

| EXAMPLE VALUE | 545 | 790 | - | 40.5 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*300 | 3.2*350 | 4.0*350 | ||||||||

| ELECTRICITY (Amp) |

H/W | 69-95 | 70-115 | 95-145 | |||||||

| O/W | 60-80 | 65-105 | 80-135 | ||||||||