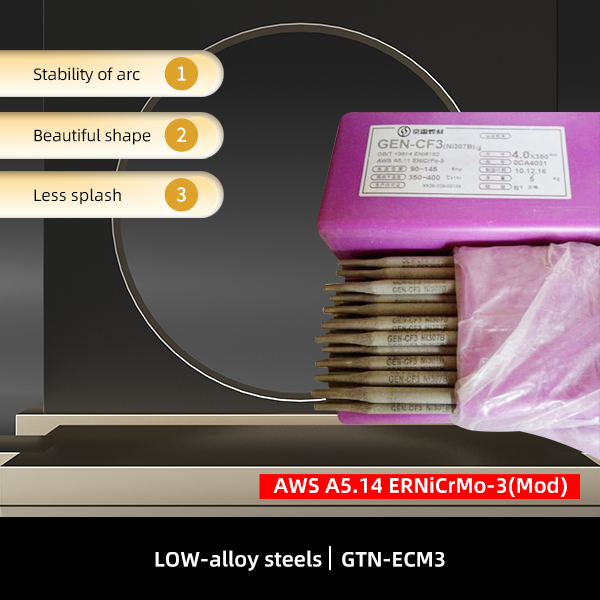

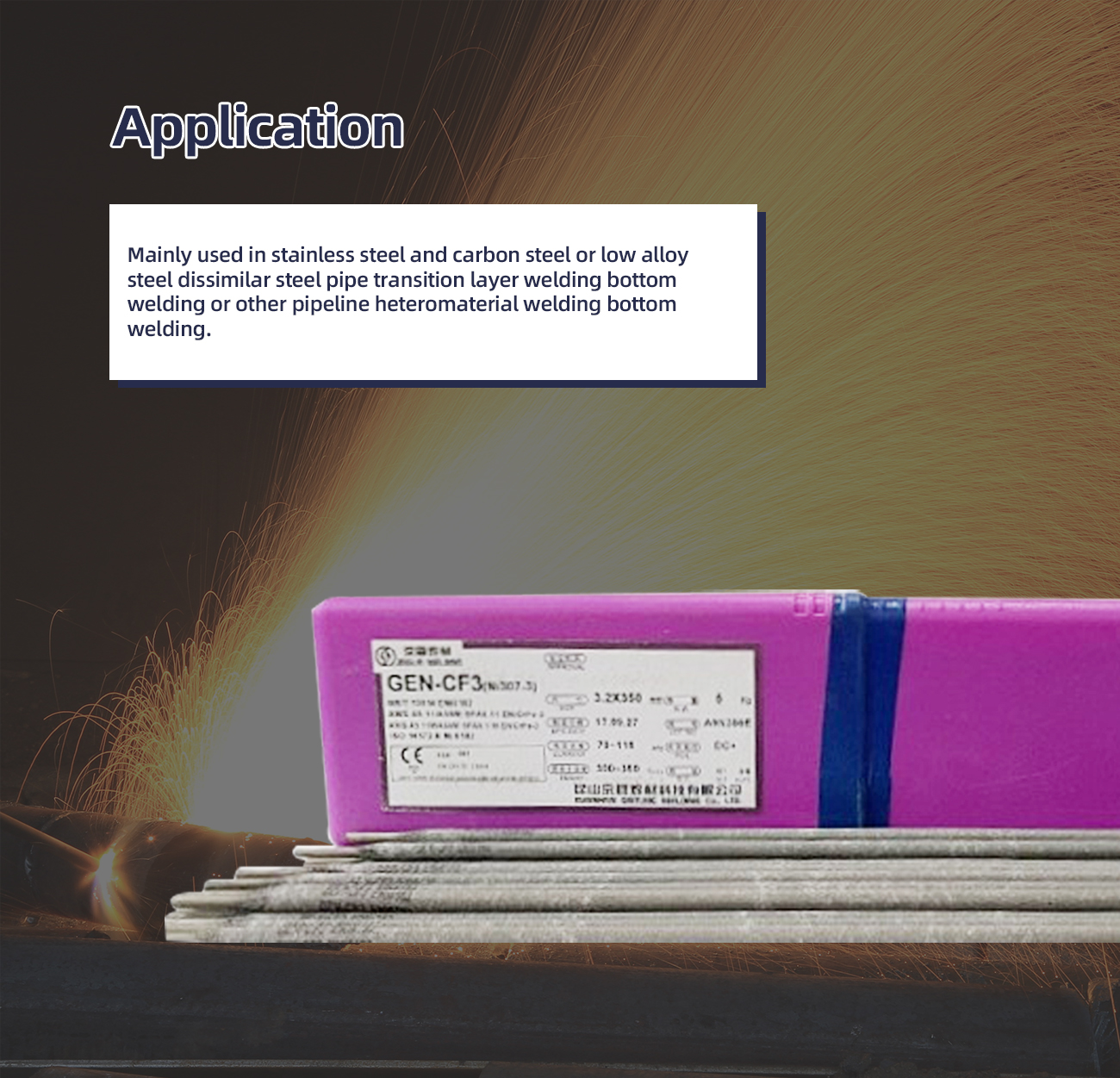

Nickel alloys Manual electrode ERNiCrMo-3(Mod) Soldering connection

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Fe | Nb+Ti |

| EXAMPLE VALUE | 0.01 | 0.12 | 0.44 | 21.7 | 62.7 | 8.25 | 0.003 | 0.003 | 0.9 | 3.41 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| EXAMPLE VALUE | - | 765 | - | 38 | ||||

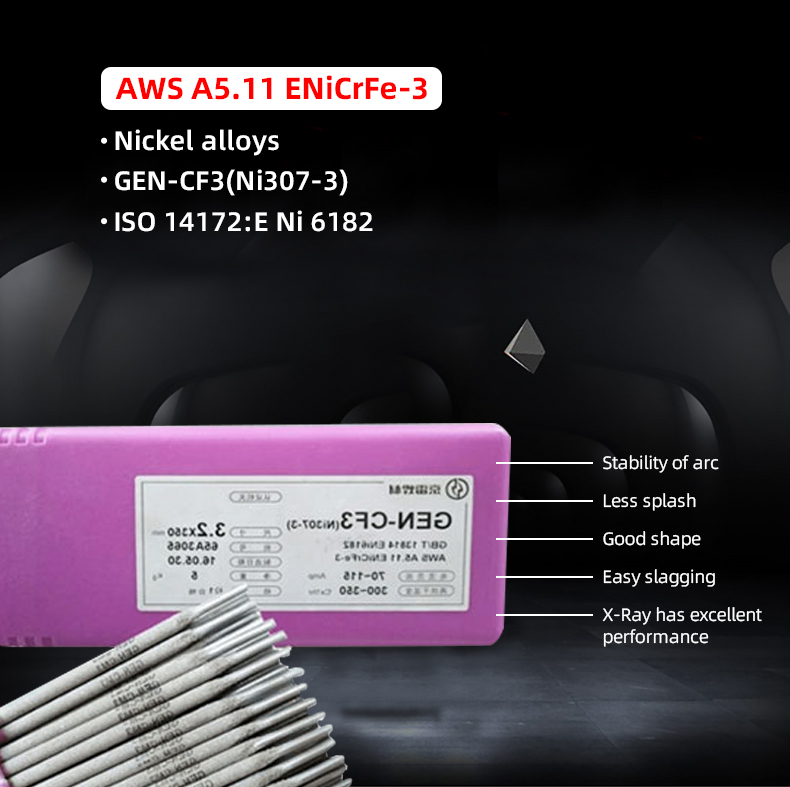

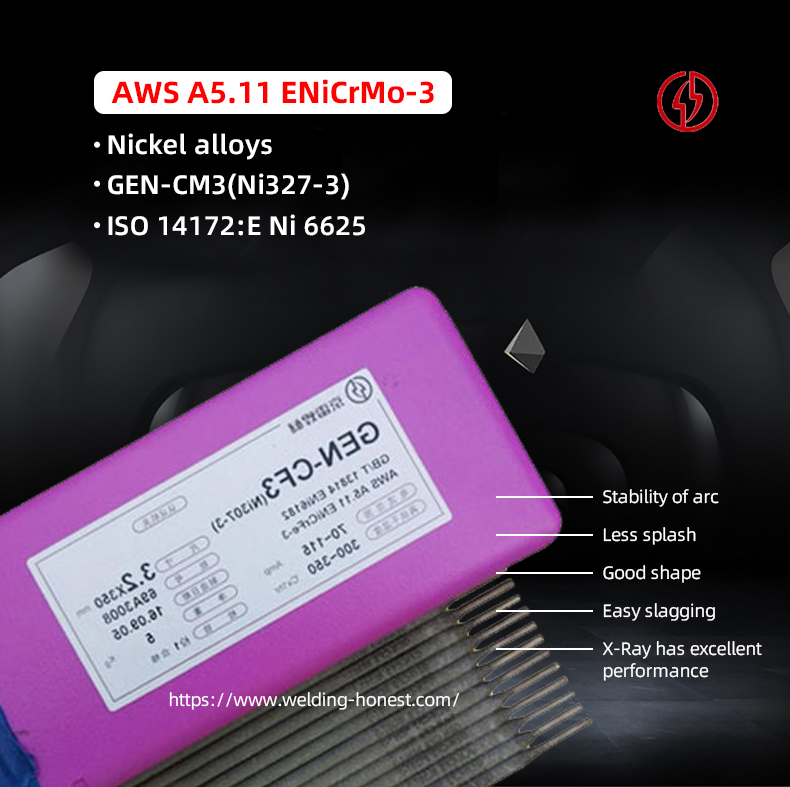

The main composition is 61Ni-22Cr-9Mo-3.5Nb+Ta, which is the most widely used nickel-chromium-molybdenum welding material.

When the self-protective TIG welding wire is welding, the protective coating will penetrate into the back of the weld pool, and form a dense protective layer uniformly on the front and back of the weld passage, so that both sides of the weld passage are not oxidized. The single-side welding is formed on both sides, and the welding slag will automatically fall off after the weld passage is cooled.

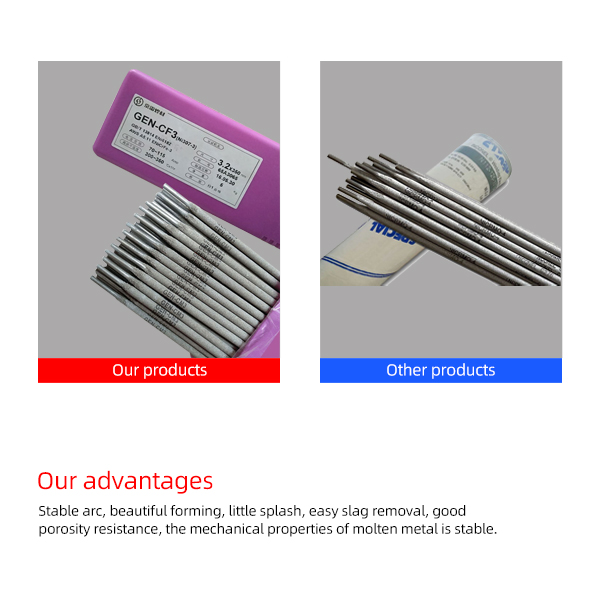

The welding method of the wire is exactly the same as that of the ordinary nickel based argon arc welding wire. The special coating on the surface has no adverse effect on the weldability and mechanical properties. The arc is stable, the forming is beautiful, and the flow of hot metal is good.

-

Shaanxi Pucheng -50℃ propane spherical tank project

-

2.3 million barrels of SBM Fast4ward FPSO

-

Shandong Nuclear power CV20

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Fe | Nb+Ti |

| EXAMPLE VALUE | 0.01 | 0.12 | 0.44 | 21.7 | 62.7 | 8.25 | 0.003 | 0.003 | 0.9 | 3.41 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| EXAMPLE VALUE | - | 765 | - | 38 | ||||